A resource treatment process of domestic organic waste

A technology of organic waste and treatment process, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., to achieve the effect of improving utilization rate, solving material corruption and odor, and avoiding soil and water pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

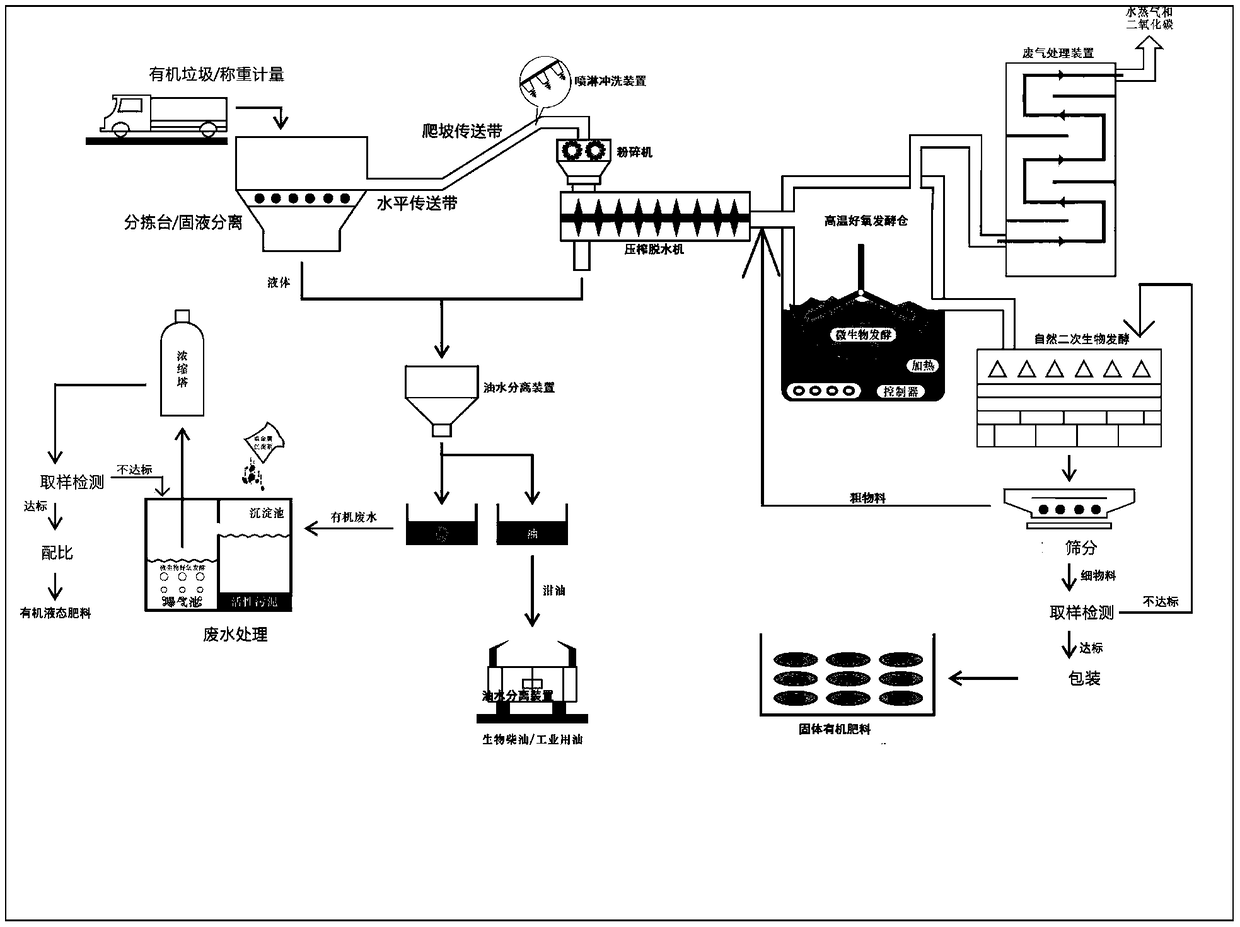

[0028] A recycling process for domestic organic waste, comprising the following steps:

[0029] (1) Domestic organic waste is collected, measured and weighed and dumped on a sorting table with a solid-liquid separator to achieve preliminary solid-liquid separation. Eliminate unprocessable non-organic substances visible to the naked eye, including porcelain, glass, and metal;

[0030] (2) The domestic organic waste after preliminary separation and sorting by the sorting table enters the horizontal conveyor belt, and the domestic organic waste is spread out on the horizontal conveyor belt, and can be sorted again to remove the non-organic matter hidden in the domestic organic waste;

[0031] (3) After the domestic organic waste passes through the horizontal conveyor belt, it enters the climbing conveyor belt. The top of the climbing conveyor belt is equipped with a spray washing device, which can reduce the oil stains and adhered metal cations on the surface of the domestic orga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com