A new method for the synthesis of reduced direct black rb

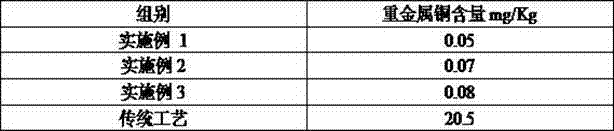

A new method and direct technology, applied in the field of reduction direct black RB dye synthesis process, can solve the problems of excessive heavy metals, containing refined naphthalene, change, etc., achieve the effect of environmental protection crystal form, performance improvement, and solve the effects of heavy metals exceeding the standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A kind of new method of synthetic reduction direct black RB is characterized in that, it comprises the following steps:

[0017] (1) Preparation of crude product: 80 kg of anhydrous sodium acetate, 500 kg of refined naphthalene, 50 kg of tetrabromogold orange, 100 kg of aminoviolanthrone, 50 kg of 1-aminoanthraquinone, 25 kg of copper oxide, and 5 kg of anhydrous sodium carbonate Put it into the reactor for condensation reaction. The reaction conditions are to heat up to 130°C and then start to stir at 60r / min. When the temperature continues to rise to 180°C, stir at 180r / min. When the temperature reaches 180-250°C, keep warm for 10-20 hours , the crude product is obtained after steaming naphthalene after the heat preservation is over;

[0018] (2) Refining of crude product: Put the crude product obtained in step (1) into the reactor, then add 300 kg of 98% sulfuric acid, mix and stir for 15 minutes, then slowly add 5 kg of sodium chlorate, heat up, and keep warm at 60-...

Embodiment 2

[0021] A kind of new method of synthetic reduction direct black RB is characterized in that, it comprises the following steps:

[0022] (1) Preparation of crude product: 100 kg of anhydrous sodium acetate, 800 kg of refined naphthalene, 100 kg of tetrabromogolden orange, 200 kg of aminoviolanthrone, 100 kg of 1-aminoanthraquinone, 60 kg of copper oxide, and 10 kg of anhydrous sodium carbonate Put it into the reactor for condensation reaction. The reaction conditions are to heat up to 130°C first, then start stirring at 100r / min, continue to heat up to 180°C and stir at 200r / min, and keep warm for 10-20 hours when the temperature reaches 180-250°C. After the heat preservation is over, the crude product is obtained after distilling naphthalene;

[0023] (2) Refining of crude product: Put the crude product obtained in step (1) into the reactor, then add 300-800 kg of 98% sulfuric acid, mix and stir for 15 minutes, then slowly add 5 kg of sodium chlorate, heat up, and cool at 60-1...

Embodiment 3

[0026] A kind of new method of synthetic reduction direct black RB is characterized in that, it comprises the following steps:

[0027] (1) Preparation of crude product: Add 90 kg of anhydrous sodium acetate, 700 kg of refined naphthalene, 80 kg of tetrabromogolden orange, 150 kg of aminoviolanthrone, 80 kg of 1-aminoanthraquinone, 50 kg of copper oxide, and 7 kg of anhydrous sodium carbonate Condensation reaction is carried out in the reactor, the reaction condition is to heat up to 130°C and start stirring at 80r / min, continue to heat up to 180°C and stir at 190r / min, keep warm for 10-20 hours when the temperature reaches 180-250°C, keep warm The crude product is obtained after distilling naphthalene at the end;

[0028] (2) Refining of crude product: Put the crude product obtained in step (1) into the reactor, then add 300-800 kg of 98% sulfuric acid, mix and stir for 15 minutes, then slowly add 5 kg of sodium chlorate, heat up, and cool at 60-100°C Heat preservation react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com