Method for preparing bricks from stale refuse landfill humus soil

A landfill and humus soil technology, applied to clay products, applications, household appliances, etc., can solve the difficult problems of large-scale landscaping soil and backfill soil, and achieve a high degree of utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The content of the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

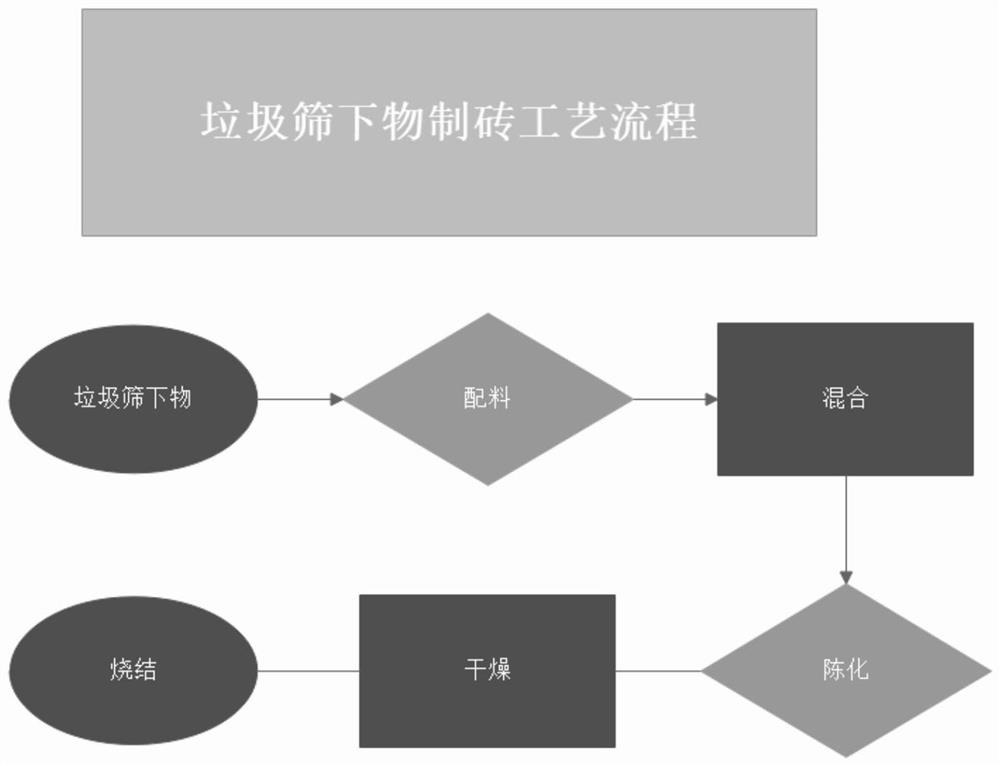

[0026] When concretely implementing the method for making bricks with the humus soil of the stale landfill provided by the present invention, the following steps are adopted:

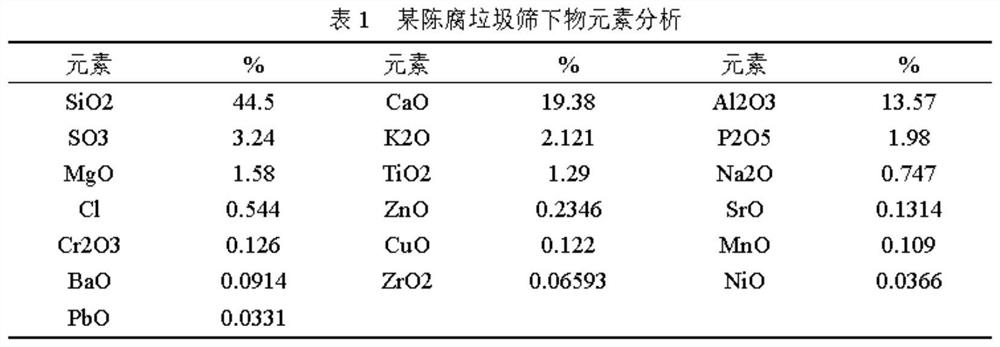

[0027] (1) Analyze and test the composition of the humus, and select a suitable humus

[0028] like figure 2 According to the analysis of the composition and phase composition of the humus soil in the garbage plant, silicon mainly exists in the form of silicon dioxide; calcium mainly exists in the form of carbon calcium; aluminum mainly exists in the form of halloysite , the iron element mainly exists in the form of iron oxide and ferric oxide.

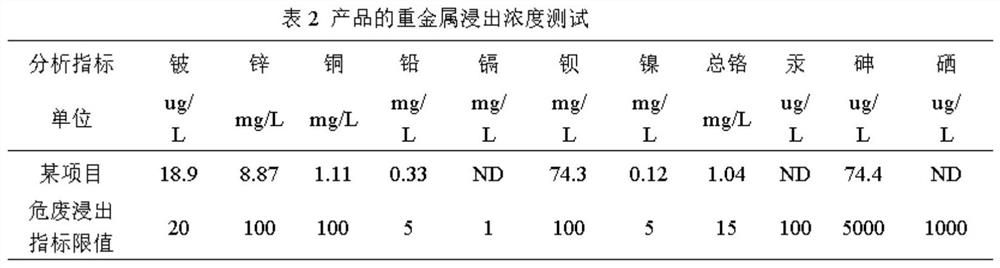

[0029] Combined with the chemical composition analysis of humus, the chemical composition of humus in the mineralized waste is relatively close to the raw materials for sintered bricks. Adding some mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com