Method for removing organic matters in decarburization unit of coal-to-liquid device

A coal-to-oil and organic matter technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of solution foaming, flooding of liquid, affecting the safe operation of decarbonization effect devices, etc. Simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

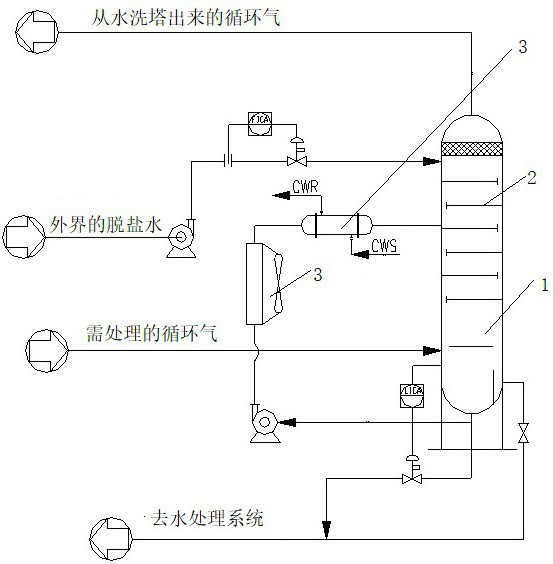

Image

Examples

Embodiment 1

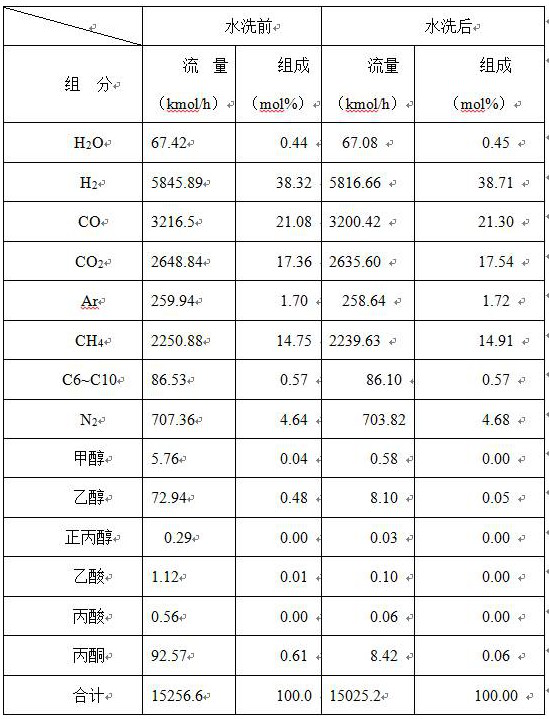

[0028] Three layers of trays are installed on the top of the water washing tower, and the total gas volume of the circulating gas before entering the tray washing is about 15256.6Kmol / h, and the main components are hydrogen, carbon monoxide, water and carbon dioxide. The specific components are shown in Table 1 (before washing), The operating pressure is about 1.7MpaG, the gas temperature is about 40°C, and 3 tons of regeneration gas condensate is introduced on the tray. After the regeneration gas is washed with washing water, the concentration of organic matter drops by about 91%. The specific composition after washing is shown in Table 1 ( after washing). After the circulating gas is washed with water, the content of organic matter in the subsequent absorption tower is greatly reduced. In addition, the washing water rich in organic matter is sent to water treatment. The concentration of organic matter is high and the water volume is small, which is convenient for treatment. ...

Embodiment 2

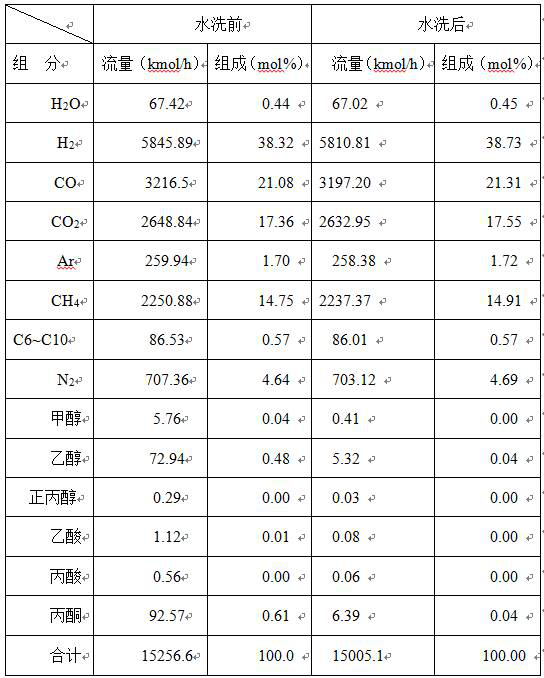

[0031] Three layers of trays are installed on the top of the water washing tower, and the total gas volume of the circulating gas before entering the tray washing is about 15256.6Kmol / h, and the main components are hydrogen, carbon monoxide, water and carbon dioxide. The specific components are shown in Table 2 (before washing), The operating pressure is about 1.9MpaG, the gas temperature is about 40°C, and 3 tons of regeneration gas condensate is introduced on the tray. After the regeneration gas is washed with washing water, the concentration of organic matter drops by about 93%. The specific composition after washing is shown in Table 2 ( after washing). After the circulating gas is washed with water, the content of organic matter in the subsequent absorption tower is greatly reduced. In addition, the washing water rich in organic matter is sent to water treatment. The concentration of organic matter is high and the water volume is small, which is convenient for treatment. ...

Embodiment 3

[0034] A layer of packing is set on the top of the water washing tower, in which the total gas volume of the circulating gas is about 15256.6Kmol / h before entering the tray washing, the main components are hydrogen, carbon monoxide, water and carbon dioxide, the operating pressure is about 1.9MpaG, and the gas temperature is about At 40°C, 3 tons of regeneration gas condensate was introduced on the tray. After the regeneration gas was washed with washing water, the concentration of organic matter dropped by about 92%. After the circulating gas is washed with water, the content of organic matter in the subsequent absorption tower is greatly reduced. In addition, the washing water rich in organic matter is sent to water treatment. The concentration of organic matter is high and the water volume is small, which is convenient for treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com