Liquid phase purification method and purification device for Bayer process aluminum oxide production system

A technology of production system and purification device, which is applied in the preparation of alkali metal aluminate/alumina/aluminum hydroxide, chemical instruments and methods, and aluminum compounds, etc. Harsh and other problems, to achieve the effect of reducing material viscosity and scarring rate, reducing organic carbon content, and reducing process energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

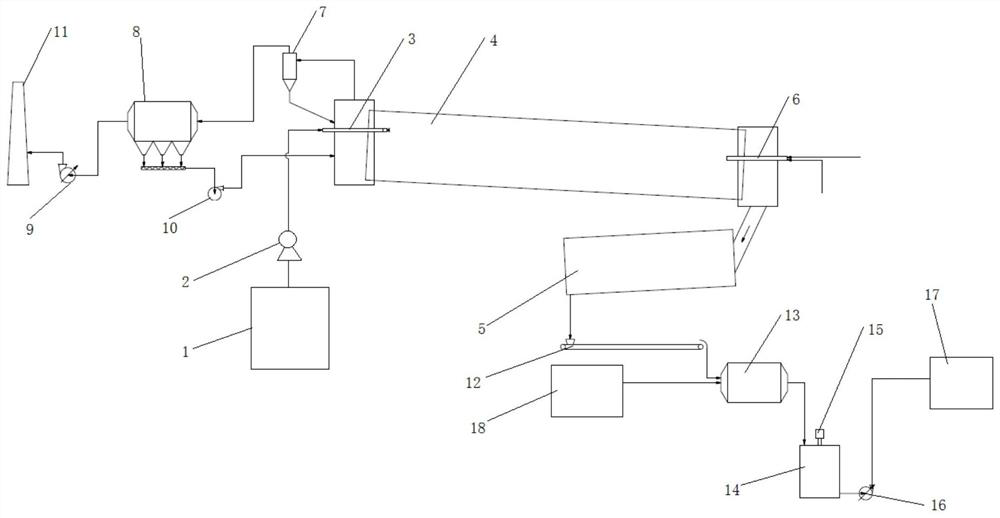

[0043] as Figure 1 As shown, a purification device for the liquid phase purification method of bayer alumina production system, comprising a mixing tank 1, a rotary kiln 4, a cooler 5;

[0044] The tail of the rotary kiln 4 is equipped with a atomizing spray gun 3, and the kiln head of the rotary kiln 4 is equipped with a burner 6;

[0045] Between the mixing tank 1 and the rotary kiln 4 is installed with a diaphragm pump 2, the diaphragm pump 2 pumps the raw material slurry into the atomization spray gun 3, and the atomization spray gun 3 is sprayed into the rotary kiln 4;

[0046] Rotary kiln 4 is connected to the tail of the kiln with a purification system;

[0047] The purification system comprises a cyclone dust collector 7 and an electric bag dust collector 8, the gas outlet of the cyclone dust collector 7 is connected with the gas inlet of the bag collector 8, and the gas outlet of the electric bag collector 8 is connected to the induced fan 9; through the induced draft fa...

Embodiment 2

[0057] Using the purification device of Example 1, the liquid phase of the Bayer method alumina production system is purified, the main process is as follows:

[0058] (1) Preparation of raw material pulp: The solid materials such as ore, hydrogen aluminum, alumina and other solid materials in the Bayer method alumina production system are mixed with evaporated mother liquor to obtain raw material pulp. Among them, the composition of the evaporated mother liquor is shown in Table 1;

[0059] Table 1 Components and content of evaporated mother liquor (unit: g / L)

[0060] ingredients Al 2 O 3

[0061] (2) Clinker sintering:

[0062] With the diaphragm pump 2, the raw material slurry is sprayed into the kiln by atomizing spray gun 3 self-rotating kiln 4 kiln tail, and then after drying, preheating, decomposition and sintering, sodium aluminate clinker is obtained, and the clinker enters the single barrel cooler 5 to cool and set aside;

[0063] During the sintering proces...

Embodiment 3

[0075]On the basis of Example 2, step (1) of Example 3, the total molecular ratio of sodium oxide to alumina is 1.0:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com