Ultraviolet light curing post-processing method for printing electrode

A technology of printing electrodes and ultraviolet light, applied in the post-processing, printing and other directions of printing, can solve the problems of increasing the complexity of the process, increasing the roughness of the Ag film, and lack of research on the roughness, achieving short curing time and low resistance. rate and roughness, the effect of surface uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Substrate cleaning: Put the substrate into an ultrasonic cleaner, and use recovered isopropanol, recovered tetrahydrofuran, alkaline cleaning solution, deionized water, deionized water, and isopropanol to ultrasonically shake for 10 minutes respectively.

[0040] (2) Substrate drying: Put the cleaned substrate into an oven and dry it at 80°C.

[0041] (3) Experimental parameter setting: set the distance from the nozzle to the stage as 1000um, design the printed pattern as a square of 8mm*8mm, set the distance between the center of the ink droplet to 35um, the speed of the ink droplet to 2m / s, and the temperature of the stage to 30°C , The nozzle temperature is 30°C.

[0042] (4) Thin film printing: use a printer to print preset graphics on the substrate.

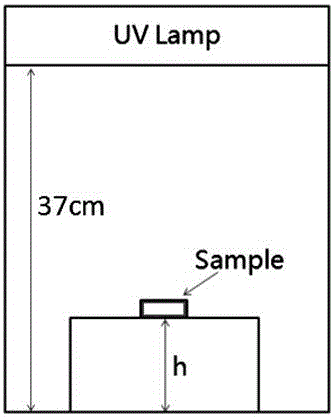

[0043] (5) UV curing: Put the printed substrate into the UV curing instrument, adjust the height of the lifting table in the UV curing instrument to h=0cm, that is, 37cm away from the UV lamp, and set the curing ti...

Embodiment 2

[0048] (1) Substrate cleaning: Put the substrate into an ultrasonic cleaner, and use recovered isopropanol, recovered tetrahydrofuran, alkaline cleaning solution, deionized water, deionized water, and isopropanol to ultrasonically shake for 10 minutes respectively.

[0049] (2) Substrate drying: Put the cleaned substrate into an oven and dry it at 80°C.

[0050] (3) Experimental parameter setting: set the distance from the nozzle to the stage as 1000um, print the pattern as a square of 8mm*8mm, the distance between the center of the ink droplet is 35um, the speed of the ink droplet is 2m / s, the temperature of the stage is 30°C, and the temperature of the nozzle is 60°C ℃.

[0051] (4) Thin film printing: use a printer to print preset graphics on the substrate.

[0052] (5) UV curing: Put the printed substrate into the UV curing instrument, adjust the height h of the lifting table in the UV curing instrument to 0cm, 8cm, 10cm, 12cm, 14cm, that is, the distance from the UV lamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com