Device and method for increasing directional solidification and purification yield of polysilicon through reverse centrifuging

A directional solidification, polysilicon technology, applied in chemical instruments and methods, polycrystalline material growth, crystal growth and other directions, can solve problems such as reduced product yield, low impurity removal rate, and easy reverse solidification in impurity areas, to prevent The effect of reverse diffusion and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

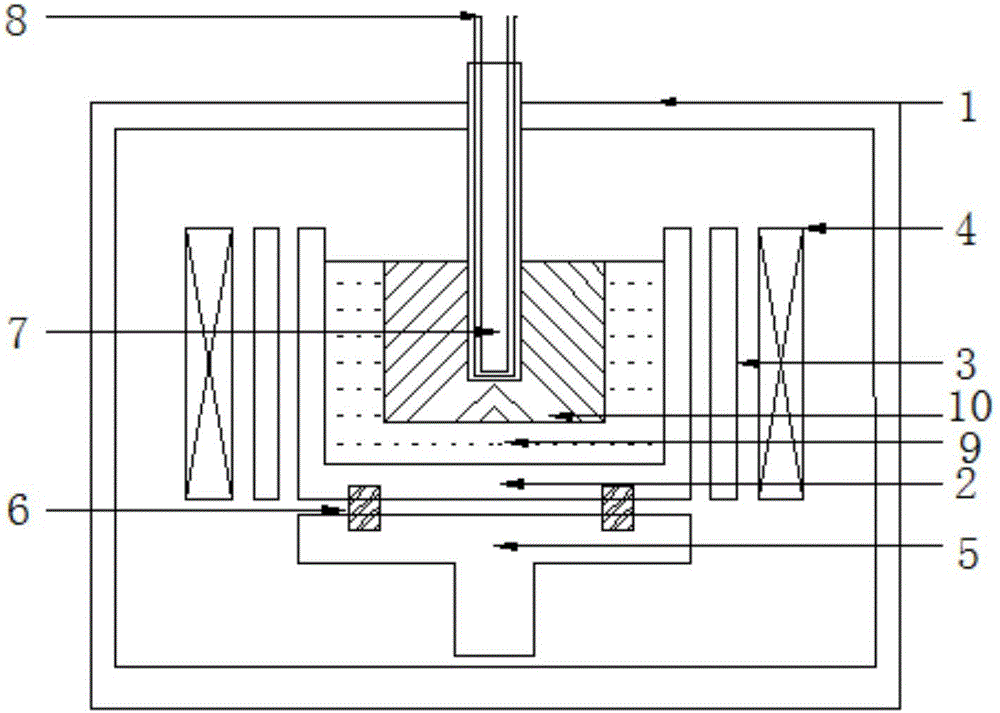

[0028] Such as figure 1 As shown, a reverse centrifugation equipment for improving the directional solidification and purification yield of polysilicon includes a furnace body 1, a silicon material container 2 located in the furnace body 1, and the side wall of the silicon material container 2 is provided with the An annular heating element 3 fixedly connected to the furnace body 1, an annular heating element 4 fixedly connected to the furnace body 1 is arranged on the outside of the annular heating element 3, a rotating tray 5 is arranged at the lower end of the silicon material container 2, and the The rotating tray 5 is fixedly connected to the lower end of the silicon material container 2 through a connecting bolt 6, and the axis of the silicon material container 2 is provided with a water cooling column 7 that can move up and down along the axis of the silicon material container 2. The column 7 is provided with a circulation channel 8 .

[0029] The material of the water...

Embodiment 2

[0034] A method for improving polysilicon directional solidification purification yield by reverse centrifugation using the equipment described in embodiment 1, has the following steps:

[0035] S1. Place the silicon material in the graphite crucible, vacuumize the furnace body 1 to 0.1-3Pa and then pour in flowing argon gas, so that the pressure in the furnace body 1 is 60000-120000Pa, and the ring induction coil is Heating the annular heating element 3 to 1550°C at a heating rate of 10°C / min and keeping it warm for 0.5-1h to obtain a completely melted silicon melt 9;

[0036] S2. After pouring cooling water into the circulating channel 8, insert the water cooling column 7 into the silicon melt 9 obtained in step S1;

[0037] S3. When the polysilicon 10 starts to solidify along the water-cooled column 7, pull the water-cooled column 7 at a speed of 0.07mm / min-0.8mm / min, and at the same time, the graphite crucible follows the rotating tray 5 at a speed of 1- 500r / min speed ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com