Device and method for while-drilling detection of roadway roof rock Protodyakonov coefficient based on sound level meter

A technology of Platts coefficient and roadway roof, which is applied in the directions of surveying, earthwork drilling, wellbore/well components, etc., can solve the problems of using anytime and anywhere, large size of geological drilling rig, low precision, etc., to achieve a safe and reliable working environment, prevent The effect of waste support and convenient use on site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

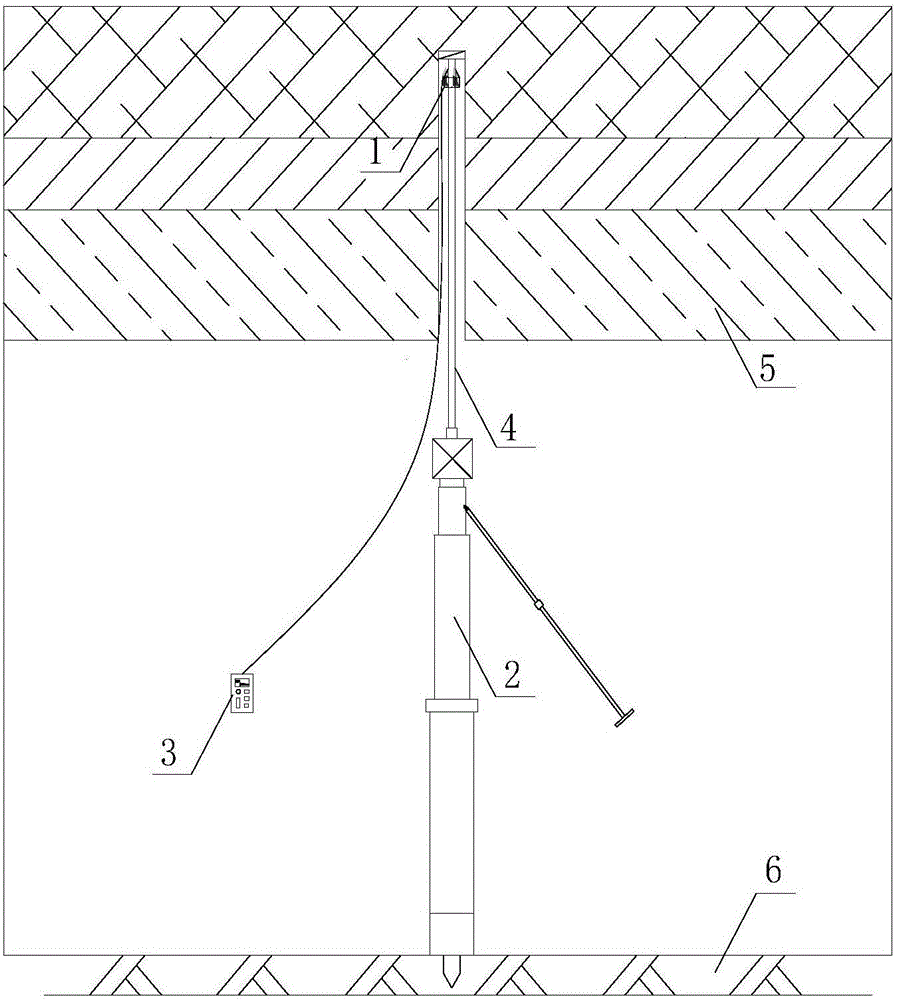

[0020] Such as figure 1 As shown, the roadway roof rock Platts coefficient detection device while drilling based on the sound level meter of the present invention includes a bearing type drilling device 1, a single rock bolt rig 2, a sound level meter 3 and a drill pipe, wherein the single rock bolt The drilling rig 2 is vertically arranged on the bottom plate 6 of the roadway. The top of the single rock bolt rig 2 is provided with a bearing-type while-drilling device 1 which is drilled into the roadway roof 5 through a graduated drill pipe 4. The bearing-type while-drilling device 1 is connected to the acoustic Level meter 3-phase connection.

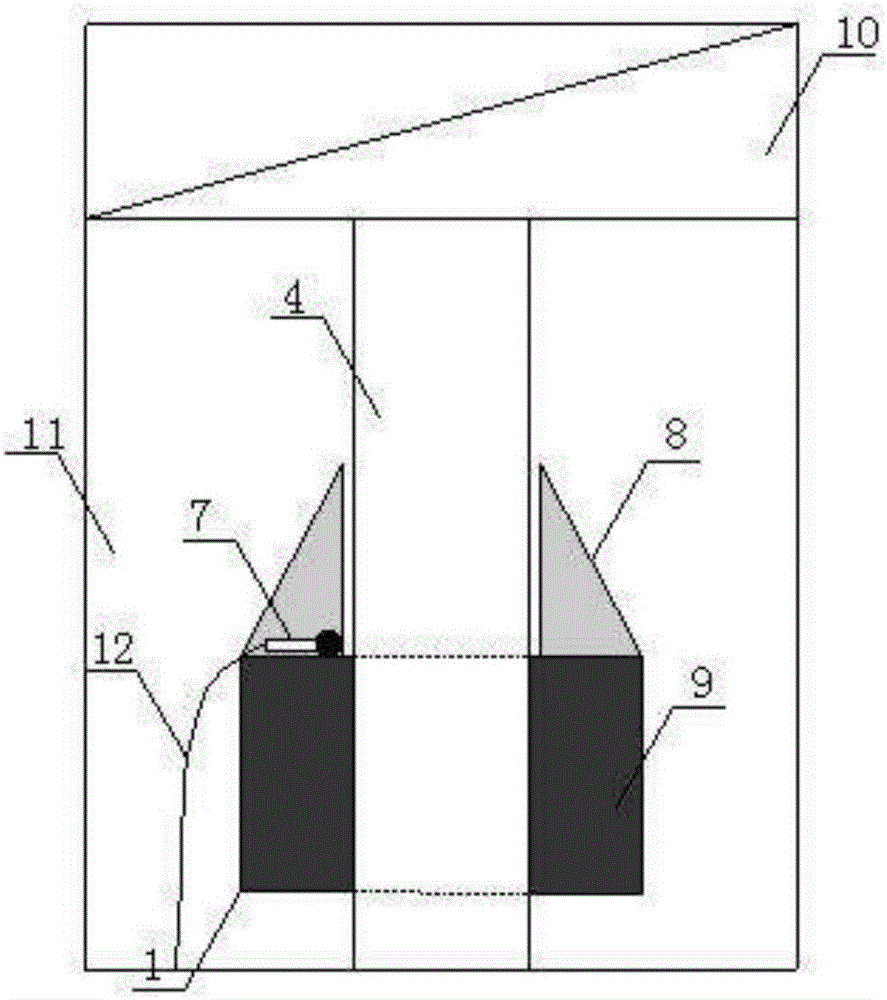

[0021] Such as figure 2 As shown, the bearing type drilling device 1 includes a sound level meter probe 7 arranged on the drill pipe, a conical member 8, a silent bearing 9 and a drill bit 10, wherein the dril...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com