Heterodyne laser vibration measuring method based on band-pass sampling

A band-pass sampling, laser vibration measurement technology, applied in measurement devices, measurement of ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of external analog devices and the existence of phase delay, limited vibration measurement accuracy, and large amount of processed data. , to achieve the effects of high vibration signal measurement accuracy, small processing data, and low sampling frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

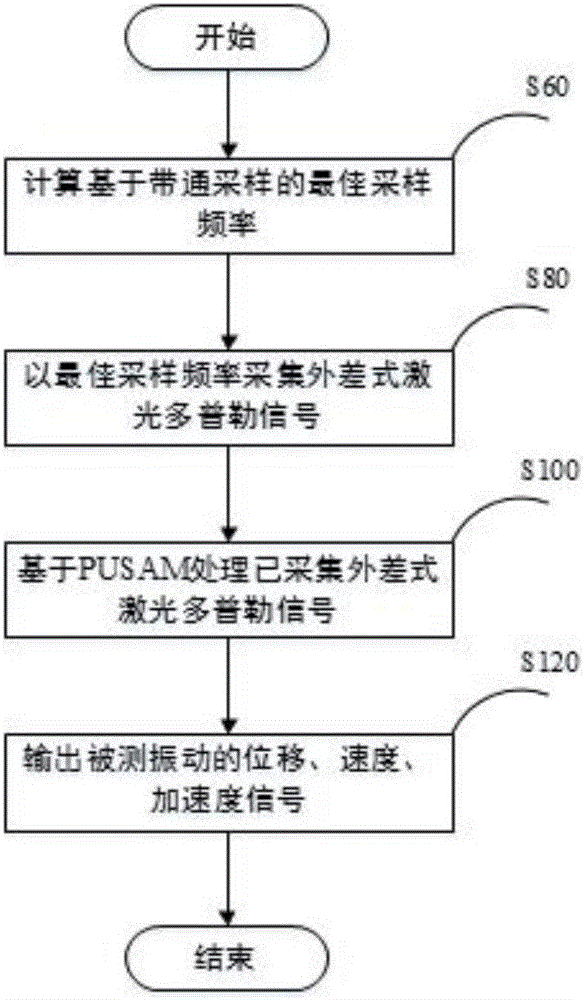

[0055] In order to solve the problems of high sampling frequency required by the existing heterodyne laser vibration measurement method, large amount of collected data and poor real-time performance, or the need for external analog devices, certain phase delay, and limited measurement accuracy, the present invention provides a A heterodyne laser vibrometer method based on band-pass sampling will be described in detail below in conjunction with the accompanying drawings and specific implementation examples.

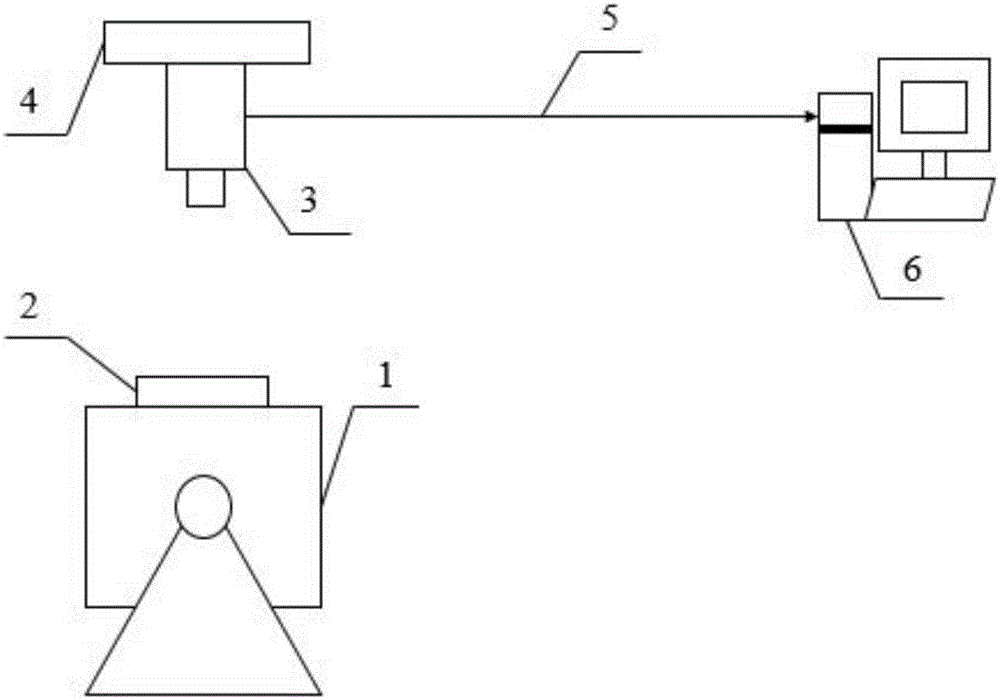

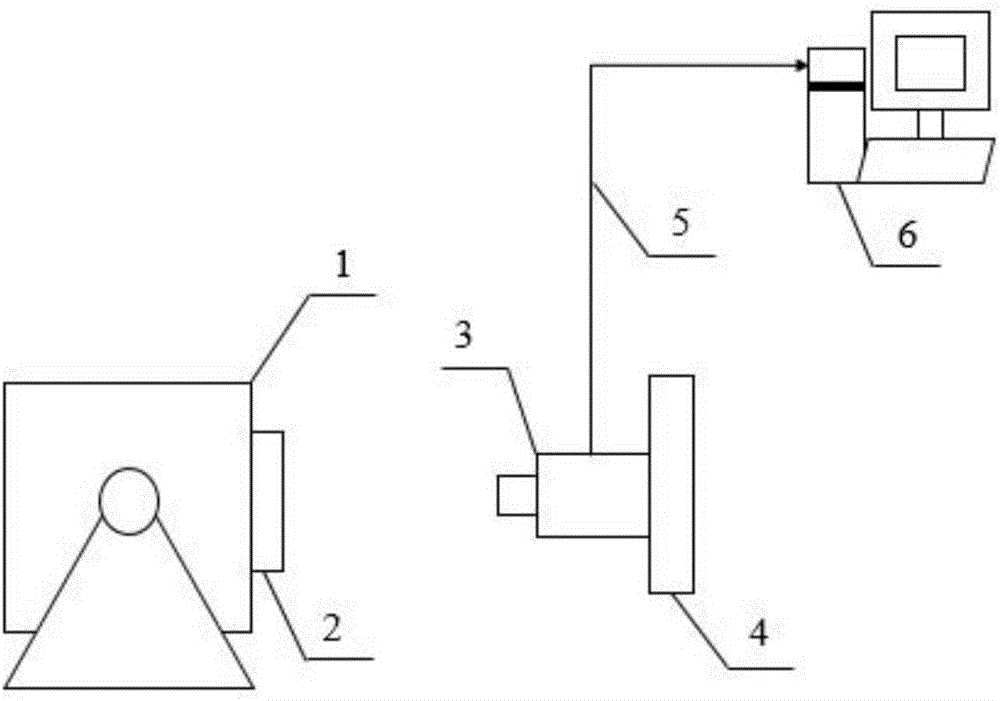

[0056] refer to figure 1 and figure 2 It is a schematic diagram of an implementation example device of the method of the present invention, and the device mainly includes: a vibrating table 1, a working surface of a vibrating table 2, a heterodyne laser interferometer 3, a vibration isolation table 4, cables 5, and signal processing and display equipment 6. The vibration isolation table 4 is used to fix the heterodyne laser interferometer 3 and is perpendicular to the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com