Simulation apparatus and simulation method for AEBS test

A simulation device and test technology, applied in the direction of measuring device, vehicle test, machine/structural component test, etc., can solve the problems of harsh test site requirements, risk of overturning, poor driving stability, etc., and achieve low test site requirements, The driving speed is high and the effect of ensuring safe passage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

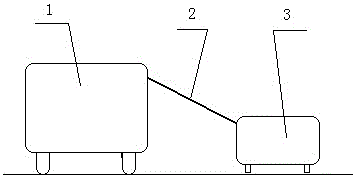

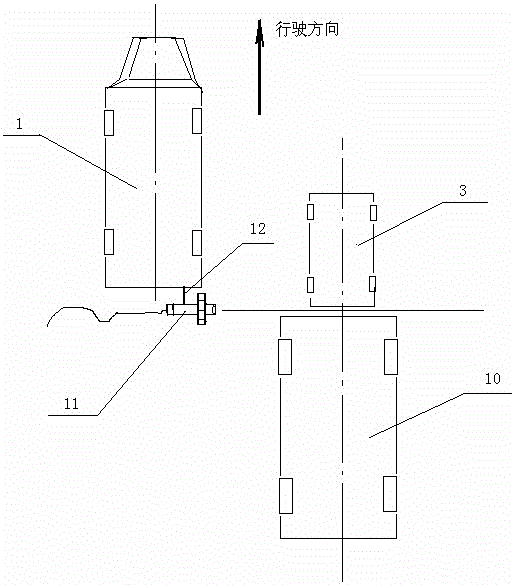

[0020] figure 1 Among them, the present invention includes traction vehicle 1, tow bar 2, moving target vehicle 3. In this embodiment, the traction vehicle 1 is a truck with a box structure, the moving target vehicle 3 is a model vehicle with a car shape, and 4 universal wheels are installed at the bottom, and the outer wrapping of the moving target vehicle 3 is a sponge-type flexible filler .

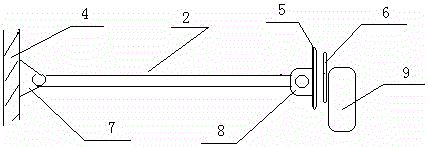

[0021] figure 2 Among them, one end of the drawbar 2 is connected with the box body 4 of the traction vehicle 1 through the pin shaft 7, the drawbar 2 can rotate around the pin shaft in the horizontal and vertical plane of the vehicle, and the other end of the drawbar 2 is equipped with an electromagnetic plate 5, so that the traction The rod 2 is connected with the electromagnetic plate 5 by a pin shaft 8, and the two can rotate relatively in the transverse and vertical plane of the automobile. The length of the traction rod 2 guarantees that when it rotates to the vertical state,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com