Pervious concrete aggregate particle size measurement method based on image processing

A technology of permeable concrete and image processing, applied in measurement devices, analysis materials, particle size analysis, etc., can solve the problem of inability to obtain the size ratio of aggregate-clogging material, poor measurement accuracy, and without considering the volume expansion rate of aggregates of hydration products, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

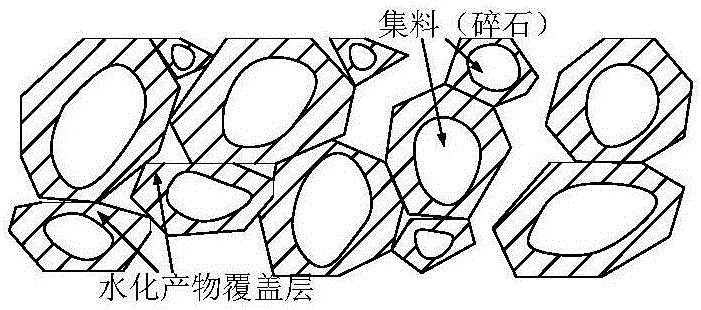

[0034] At present, in the process of making pervious concrete specimens, permeable concrete aggregates (crushed stones) are covered by cement hydration products, the size of solid particles is "increased", and the gaps between aggregates are filled, which will affect the seepage and blockage process , so this patent innovatively considers the increase in the volume of solid particles. The schematic diagram of the volume increase of solid particles is shown in figure 1 .

[0035] The volume between the solid particles of the pervious concrete specimen includes the volume of the aggregate and the volume of the hydration product covering layer. The aggregate volume expansion rate caused by hydration products can be obtained by dividing the solid volume of pervious concrete by the aggregate volume:

[0036]

[0037] Where: R V is the volume expansion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com