Method for ultrasonic distinguishing of R-region defect of composite material structure

A composite material and ultrasonic technology, applied in the analysis of materials, the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, and the use of sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., can solve complex sound wave reflection signals, defect detection and misjudgment, and influence Quantitative analysis and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

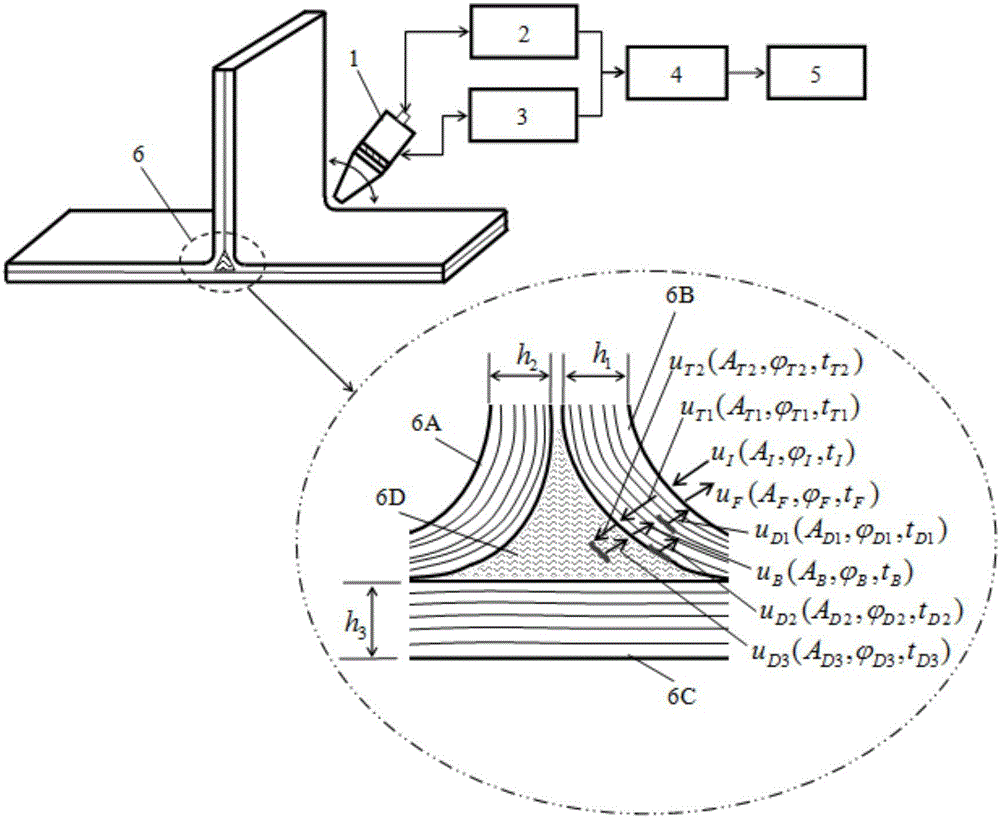

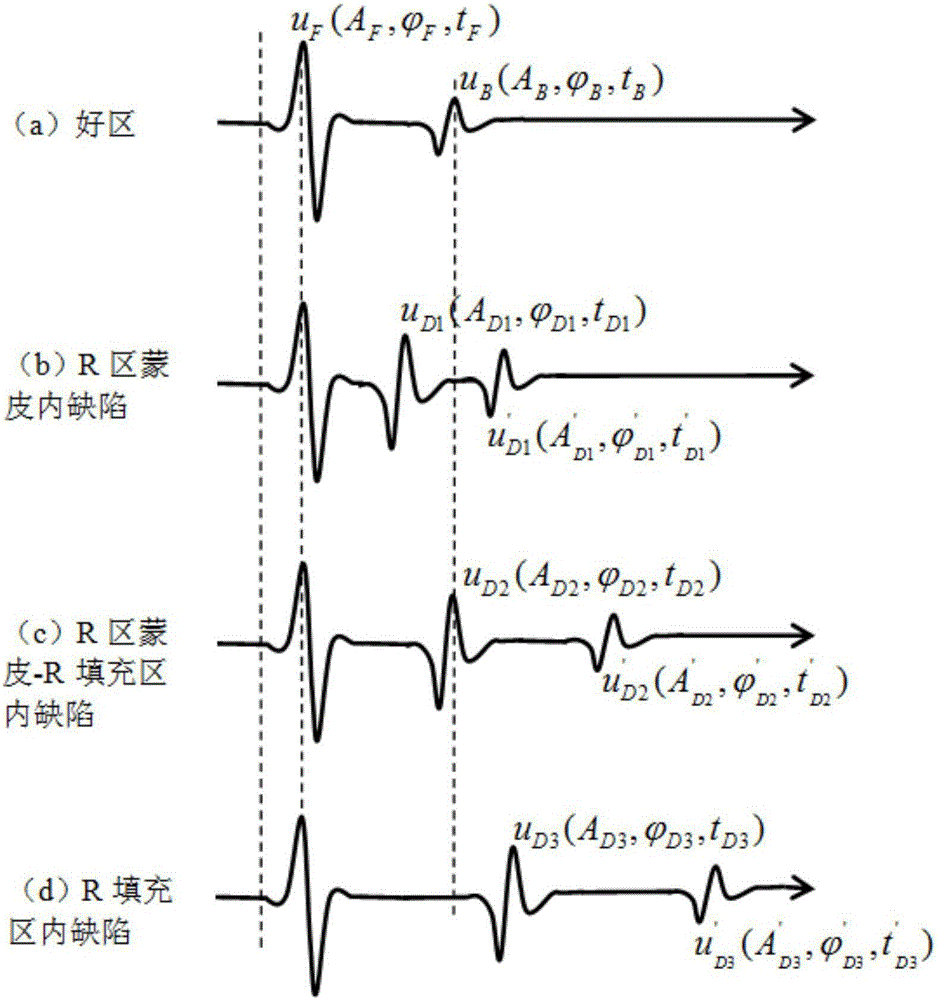

[0193] Adopt the present invention, choose the MUT-1 and FCC-D-1, FCC-B-1 ultrasonic detection instrument, CUS-21J ultrasonic detection system and FJ-1 high-resolution ultrasonic transducer produced by AVIC Composite Materials Co., Ltd., A series of practical detection applications have been carried out on the R zone of carbon fiber composite structures with different thicknesses by using water film coupling. Display mode and image mode, through manual scanning and automatic scanning detection methods, a series of detection applications have been carried out. The actual detection results show that: 1. When the ultrasonic detection detects that there is no defect inside the composite material structure R to be detected, the detection signal displayed by the display unit 5 Only in with and Both are 0; 2 When the ultrasonic detection detects that there is a delamination defect inside the skin in the composite material structure R to be detected, the detection signal displaye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com