Optimization design method for preforming technology of turbine disk forgings

An optimized design and pre-forming technology, applied in the field of forging, can solve the problems of deviation from optimization and difficult pre-forging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0025] The present invention is an optimal design method for the preforming process of a turbine disc forging. The following takes the optimal design of the preforming process for a high temperature alloy turbine disc forging as an example to introduce in detail the implementation details of the optimized method for the preforming process of a turbine disc forging designed in the present invention. , whose methods include:

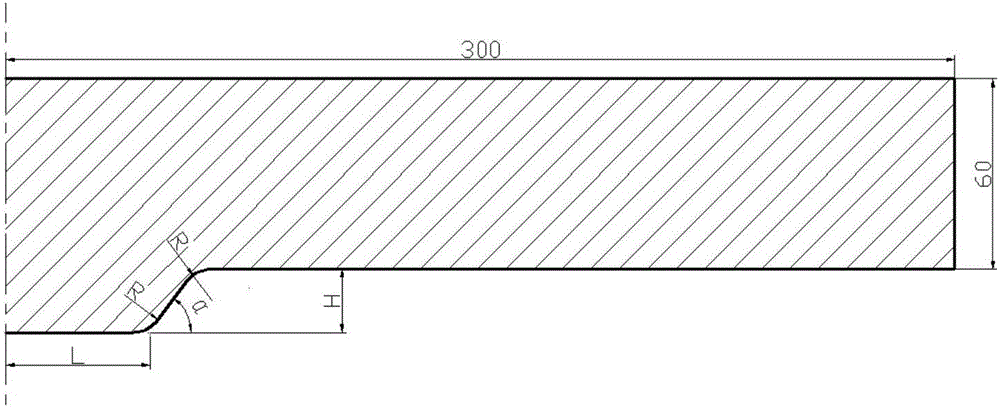

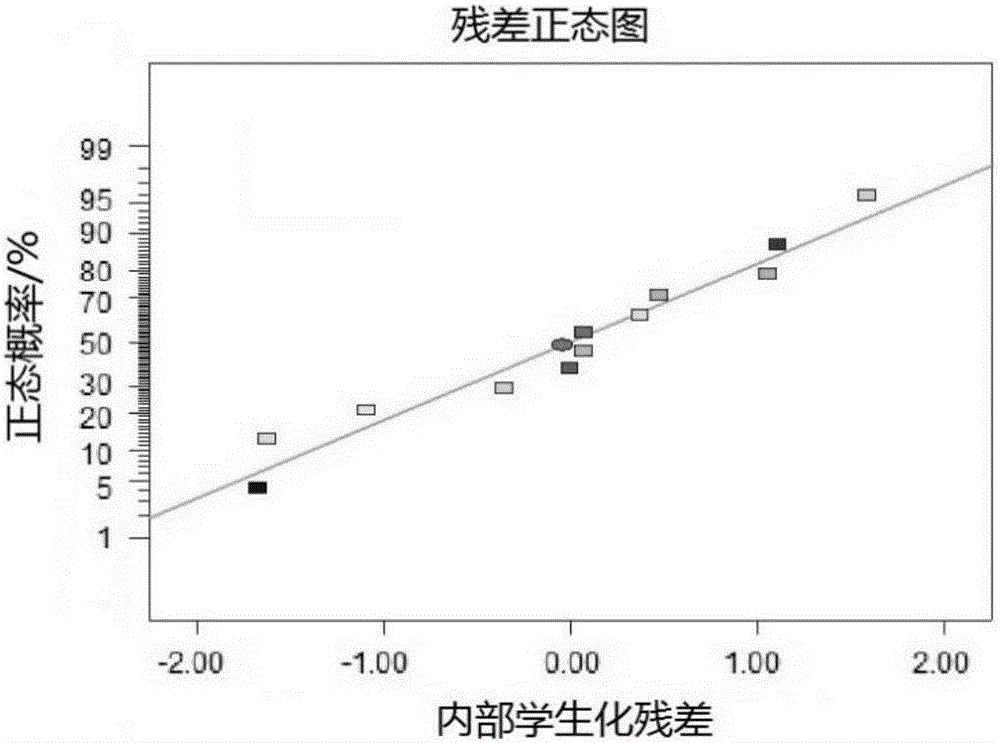

[0026] Step 1: Design the geometry of the pre-forging, parameterize its size, and use the Plackett-Burmans experimental design method to determine the key influencing parameters;

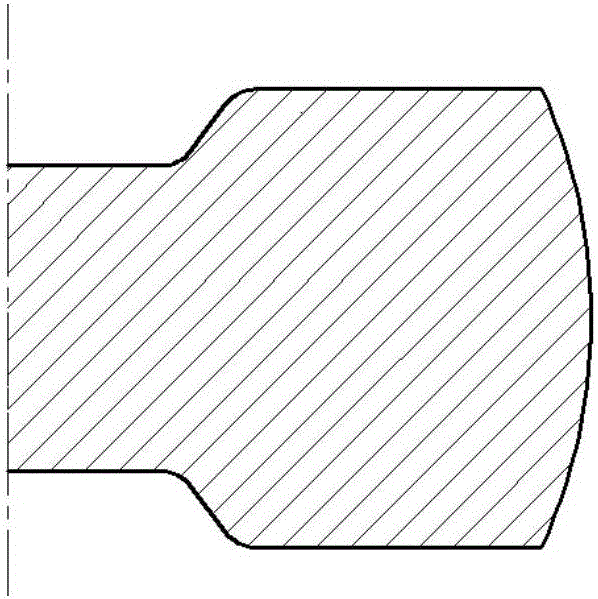

[0027] Schematic diagram of the cross-section of the superalloy turbine disc pre-forging figure 1 As shown, according to the general shape of the pre-forging, the cross-sectional schematic diagram of the pre-forging die is designed as follows ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com