Automatic soldering and testing integrated machine for inductance coil and working method of automatic soldering and testing integrated machine

An inductance coil and automatic welding technology, applied in coil manufacturing, inductance/transformer/magnet manufacturing, circuits, etc., can solve the problems of inability to guarantee product processing accuracy and processing accuracy, reducing product qualification rate, and low production efficiency. Improve accuracy and measurement accuracy, improve product qualification rate and production efficiency, and achieve the effect of automated production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

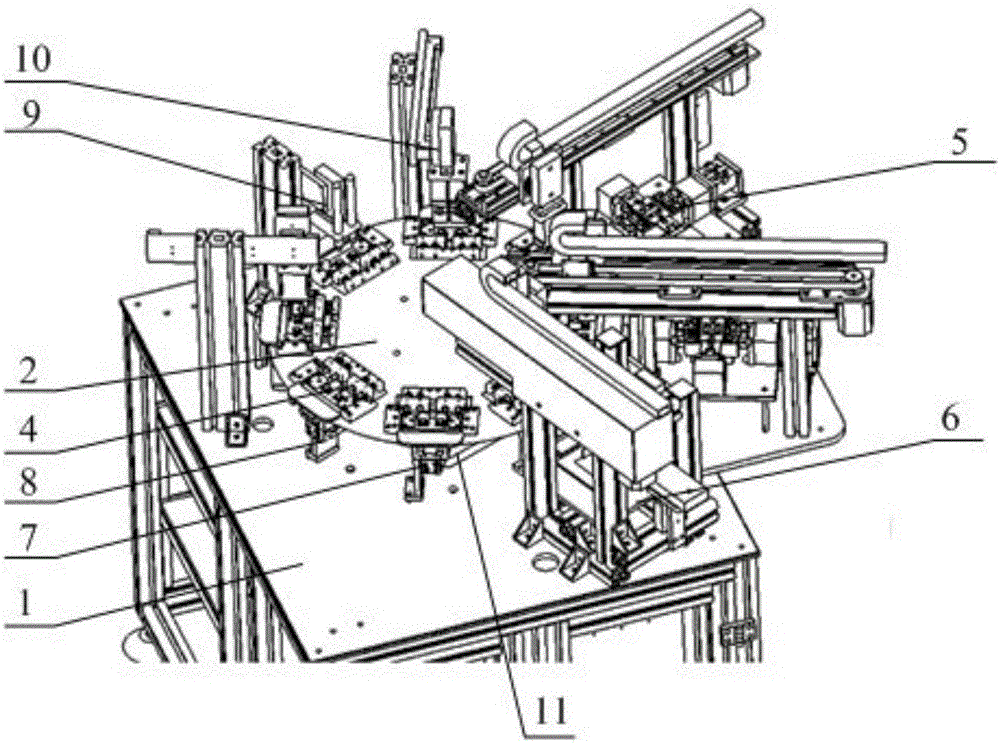

[0031] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0032] On the one hand, the present invention provides an integrated machine for automatic soldering and testing of inductance coils, such as Figure 2-7 As shown, it includes a frame 1 and a rotatable circular workbench 2 fixed on the frame 1, wherein:

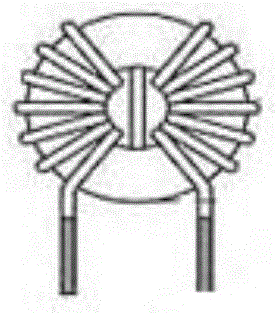

[0033] There are several stations on the workbench 2, each of which is fixed with a clamping device 4 for pinching the inductance coil 3;

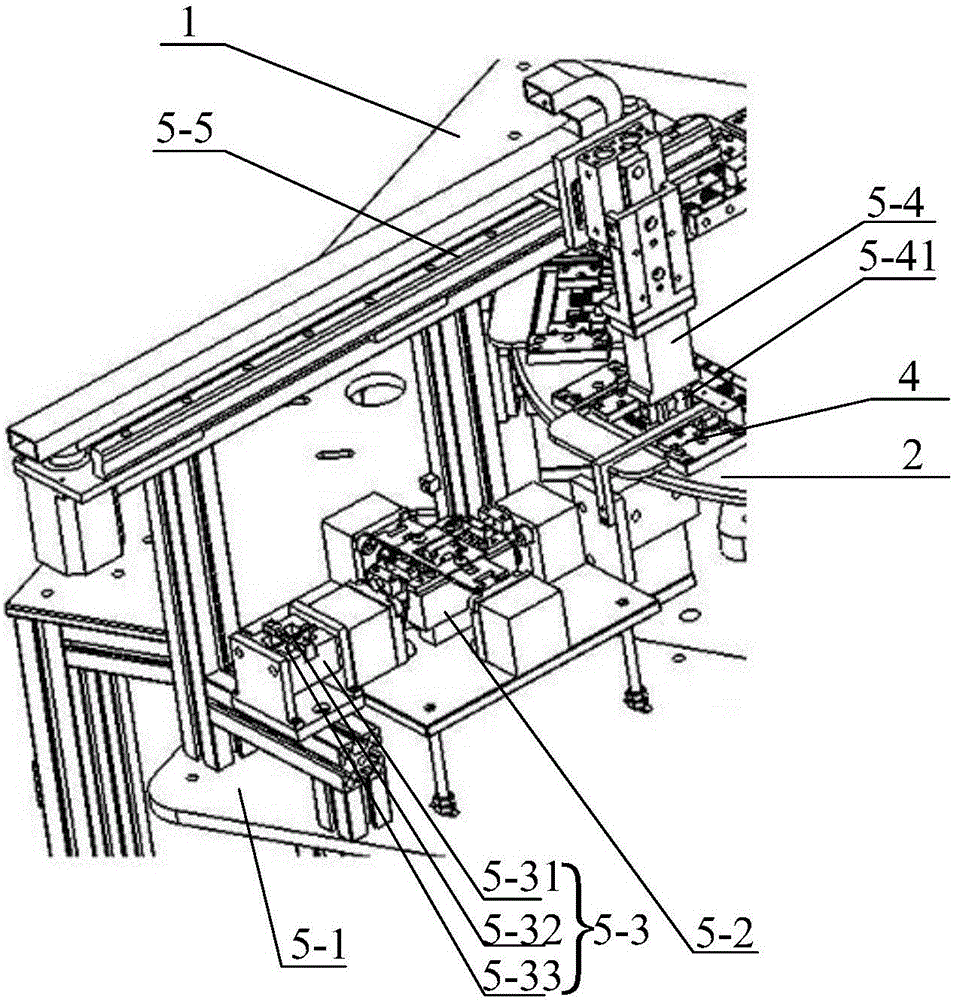

[0034] Around the workbench 2, corresponding to the work stations, there are fixed automatic trimming foot feeding mechanism 5, automatic soldering device 6, withstand voltage testing device 7 and inductance testing device 8 in sequence.

[0035] The all-in-one machine for automatic soldering and testing of inductance coils of the present invention, when processing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com