Automatic charging device of AGV

An automatic charging device and on-board charging technology, applied in the field of mobile robots, can solve problems such as short circuit, battery positive and negative polarity reversed, and achieve the effect of avoiding electromagnetic leakage or short circuit, and avoiding poor contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The automatic charging device of the AGV provided by the present invention includes an on-board charging unit arranged on the AGV and a charging stand arranged on the ground.

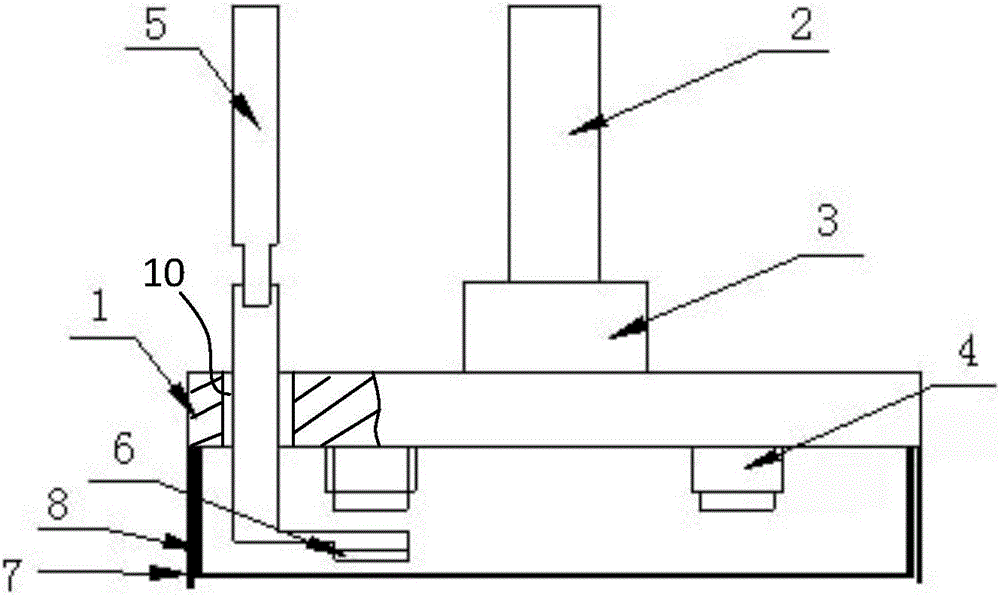

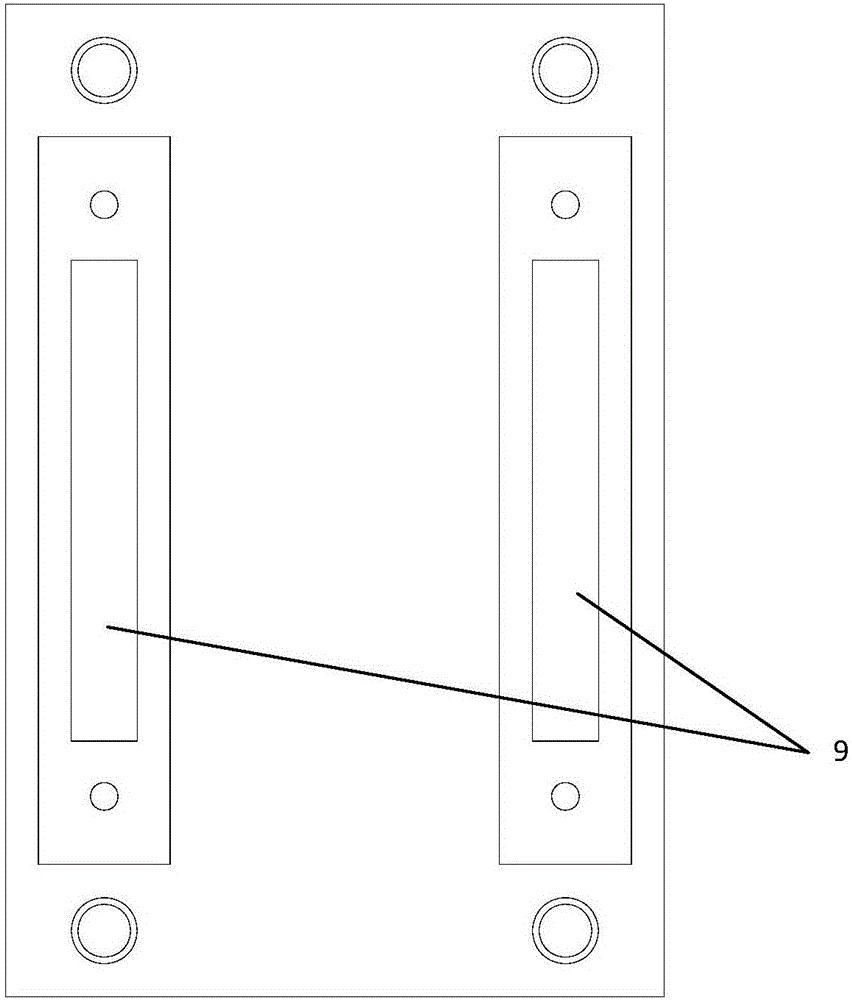

[0029] Such as figure 1 As shown, the on-board charging unit mainly includes a control unit, a base plate 1, a lift steering device composed of a first motor and a first electric cylinder 2, a steering sleeve 3, two on-board electrodes 4, and a second motor and a second electric cylinder. 5 and a polarity detection device composed of a polarity detection copper sheet 6.

[0030] In application, since the upper end of the first electric cylinder is fixedly connected with the AGV body, in order to make the first electric cylinder and the bottom plate rotate by plus or minus 180 degrees as a whole, three schemes are adopted here: one scheme is that the upper end of the second electric cylinder is also connected with The AGV body is fixedly connected. At this time, it is necessary to set up an arc-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com