Preparation method for stitch gluing type flue gas filter bag

A filter bag and gluing technology, applied in separation methods, dispersed particle filtration, chemical instruments and methods, etc., can solve the problems of pinhole leakage and the inability of filter bags to effectively remove dust, so as to increase the tortuosity and improve the resistance to dust erosion and wear. Sexuality, the effect of improving tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

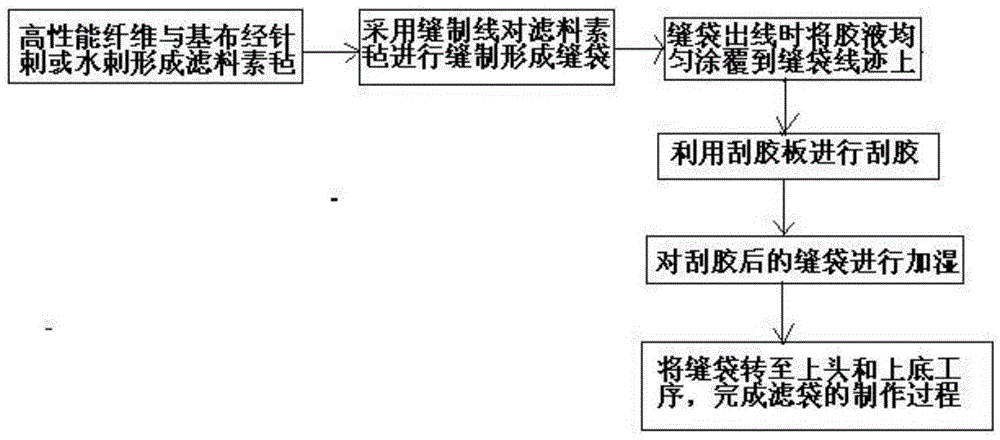

[0017] Such as figure 1 As shown, the high-performance fiber (the preferred aramid fiber in this embodiment) is added to the base cloth (the preferred polytetrafluoroethylene base cloth in this embodiment) after opening, mixing, carding, laying, and netting, the total gram of base cloth Weight is 130g / m 2 , for spunlace, to obtain a total grammage of 530g / m 2 Filter material plain felt; cut the filter material plain felt to the required width, and use the sewing line to sew the filter material plain felt to form a seam bag; set up a photoelectric sensor and a rubber preparation device at the outlet of the seam bag, among which The photoelectric sensor is connected to the gluing equipment. When the seam bag is moving, the infrared ray on the photoelectric sensor detects the movement signal, and the glue preparation device is started to press the glue to the nozzle, and the nozzle applies glue to the stitches of the seam bag. , in order to achieve uniform coating, a squeegee c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com