Method and device for determining expansion and shrinkage performance of coal for production

A technology of expansion, contraction and measurement methods, applied in measuring devices, instruments, scientific instruments, etc., can solve problems such as huge costs, and achieve the effects of reducing blast furnace fuel consumption, reducing production coal blending costs, and reducing damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

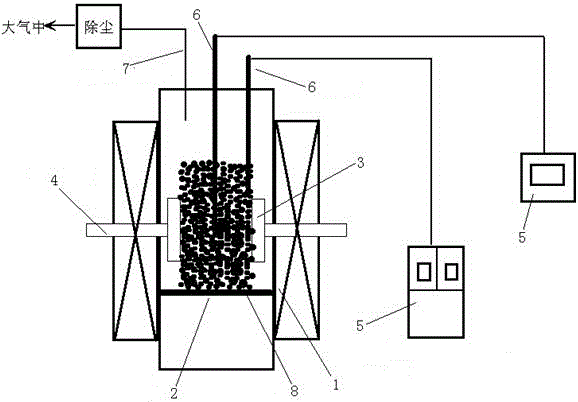

Embodiment 1

[0033] Put 2000g of coal samples with Ad content of 6%, Vd content of 25% and 80% of the coal sample to be measured with a particle size of less than 3 mm into a stainless steel tube 1Cr18Ni9Ti with an inner diameter of 100 mm and a height of 300 mm. Cardboard, the coal sample to be measured is naturally piled up to a density of 820 kg / m3 to become a coal block to be measured; after treatment, the coal block to be measured together with the cardboard is taken out of the stainless steel tube and placed in a vertical heating furnace with an inner diameter of 200mm. Heating was controlled by program, and the heating rate was 1°C / min. During the heating process, when the coal material reaches a certain temperature in the furnace, the coal sample begins to expand and contract. Diameter value, the maximum expansion rate of the coal block to be measured is calculated to be 52%, and the maximum shrinkage rate is 35%.

Embodiment 2

[0035]Put 2000g of coal samples with 80% Ad content and 27% Vd content and 80% particle size less than 3mm to be measured into a 1Cr18Ni9Ti stainless steel tube with an inner diameter of 100 mm and a height of 300 mm. Cardboard, the coal sample to be measured is compacted to a density of 1080 kg / m3 to become a coal block to be measured; after treatment, the coal block to be measured together with the cardboard is taken out of the stainless steel tube and placed in a vertical heating furnace with an inner diameter of 200mm. Heating was controlled by program, and the heating rate was 2°C / min. During the heating process, when the coal material reaches a certain temperature in the furnace, the coal sample begins to expand and contract. Diameter value, the maximum expansion rate of the coal block to be measured is calculated to be 61%, and the maximum shrinkage rate is 42%.

Embodiment 3

[0037] Put 1500g of coal samples to be measured with 10% Ad content and 28% Vd content and 83% particle size less than 3mm into a 1Cr18Ni9Ti stainless steel tube with an inner diameter of 100 mm and a height of 300 mm. Cardboard, the coal sample to be measured is naturally piled up to a density of 820 kg / m3 to become a coal block to be measured; after treatment, the coal block to be measured together with the cardboard is taken out of the stainless steel tube and placed in a vertical heating furnace with an inner diameter of 200mm. Heating was controlled by program, and the heating rate was 3°C / min. During the heating process, when the coal material reaches a certain temperature in the furnace, the coal sample begins to expand and contract. Diameter value, the maximum expansion rate of the coal block to be measured is calculated to be 89%, and the maximum shrinkage rate is 56%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com