Self-steering mechanism about the multiple land gap in the field

A field operation, self-steering technology, applied in applications, animal husbandry, devices for capturing or killing insects, etc., can solve the problems of reduced overall storage space, large horizontal space, and inability to ensure the passage of the walking chassis, to improve the space Utilization, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

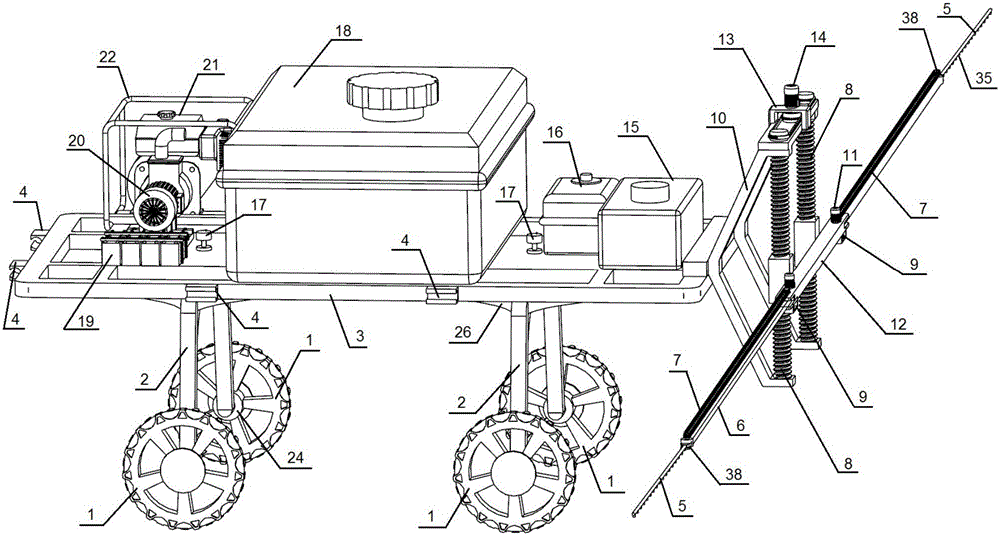

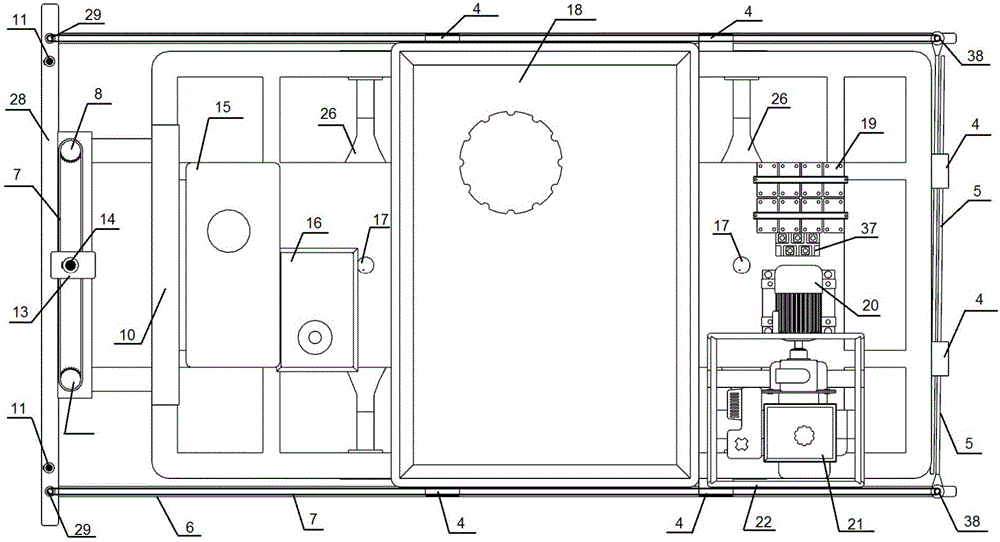

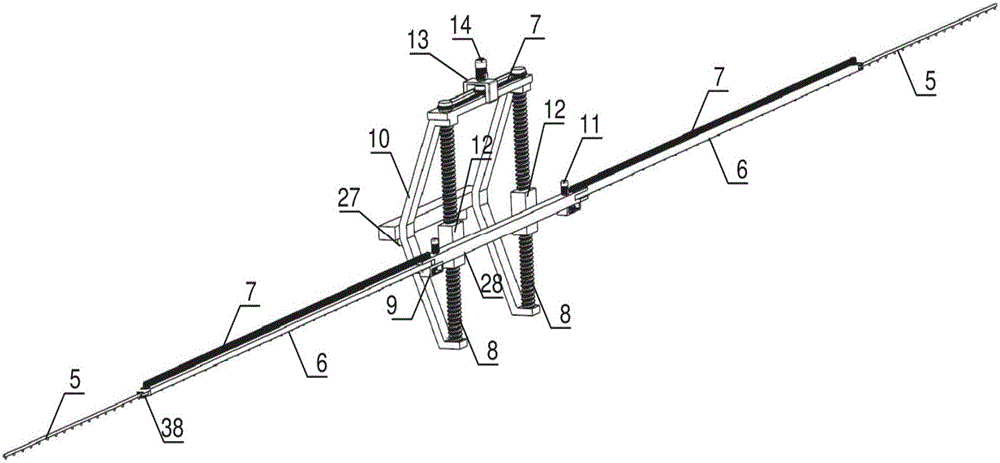

[0064] Such as Figure 5-6 As shown, the self-steering walking chassis includes a slewing mechanism and tires 1;

[0065] The car platform 3 is a metal frame welded by many square metal tubes and two square metal plates, which can effectively reduce the weight of the car platform. Many square metal tubes are welded into a 3×5 square space. Two square metal plates are fixed in the spaces of the second row and the fourth row, and spray rod placement grooves 4 are respectively welded on the front and left and right sides of the car platform 3, and 8 stoppers 23 are welded on the bottom of the car platform 3. The rear portion of the car platform 3 is reserved with a through hole 25 for the fixed central axis 27 to pass through;

[0066] Wheel 1 selects herringbone pattern agricultural tires for use, also can select other tires such as common non-pattern tires according to the demand of driving road surface, in-wheel motor 24 is housed in the wheel hub;

[0067] The slewing mecha...

Embodiment 2

[0069] Such as Figure 7 As shown, the slewing mechanism includes a single-row tapered roller bearing 39, a support column 44, a shock absorber 47 and a shock-absorbing bracket 46, and the outer ring or inner ring of the single-row tapered roller bearing 39 is connected with the vehicle platform 3 by welding, and the single-row tapered roller bearing The inner ring or outer ring of the roller bearing 39 and the top surface of the support column 44 are fixed concentrically. There are three sets of shock absorbers 47, wherein one end of the shock absorber is respectively fixed on the symmetrical sides and below of the support column 44, and the other end is respectively Be fixed on both sides and the central position of the shock absorber 46, the shock absorber 46 is a high-strength square metal frame close to the width of the car, and the two ends of the shock absorber 46 are fixed with the fuselage of the hub motor 24.

Embodiment example 3

[0071] Such as Figure 8 As shown, the self-steering running mechanism includes a slewing mechanism and a tire 1 with a hub motor 24;

[0072] The slewing structure includes plane cylindrical bearing 42, chassis platform 26 and axle 2; The hole makes the cylindrical roller 40 of the plane cylindrical bearing 42 contact with the bottom of the car platform 3, and there is a circular groove in the middle of the chassis platform 26, and there are gradually shrinking extensions on the left and right sides of the chassis platform 26, and the plane of the plane cylindrical bearing 42 maintains The frame assembly and the circular groove of the chassis platform 26 are fixed concentrically. The axle 2 is made of metal. The top of the axle 2 is fixed to the extension of the chassis platform 26 and forms an obtuse angle with the chassis platform 26. The fuselage is fixed; because the height of the vehicle axle 2 is higher than the ground, so this embodiment is applicable to the working o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com