Bamboo tube black tea baking and stewing production method

A production method and bamboo tube technology, which are applied in the directions of tea spice, tea treatment before extraction, etc., can solve the problems that the finished black tea product is not fragrant enough, the taste is not sweet enough, and there are many technological processes, so as to reduce the preparation and packaging process, have comprehensive functions, and have a good isolation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, so as to understand the essence of the present invention more clearly and intuitively.

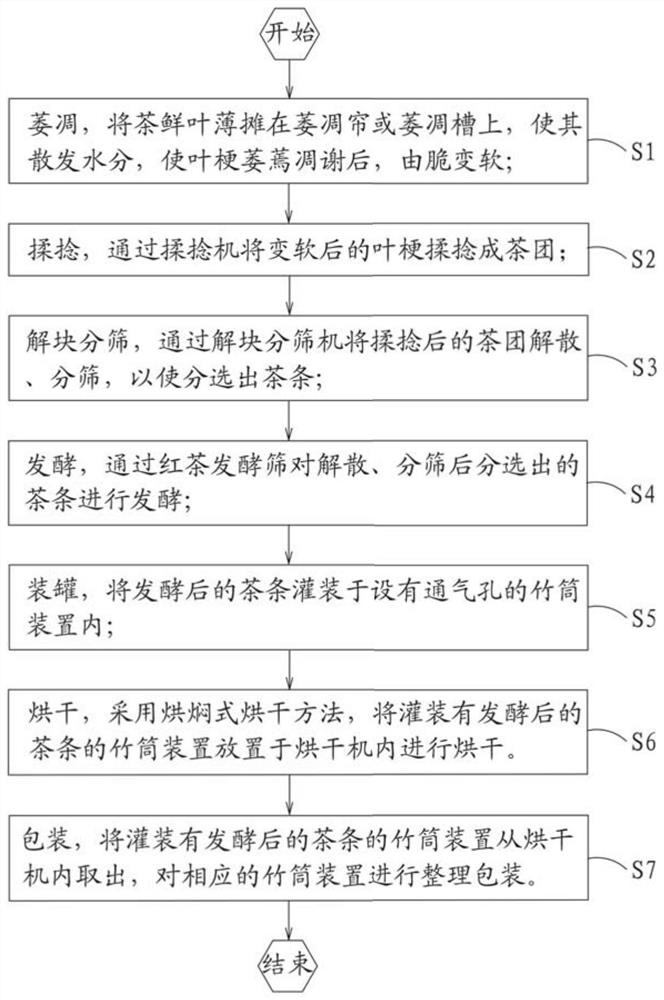

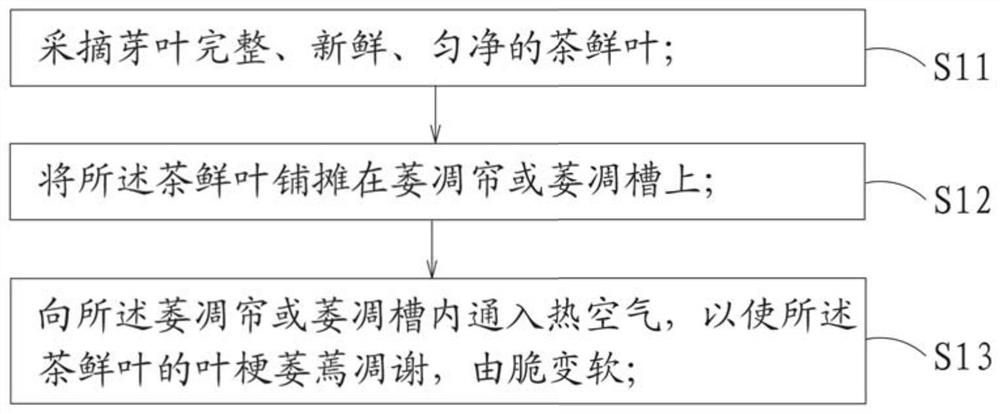

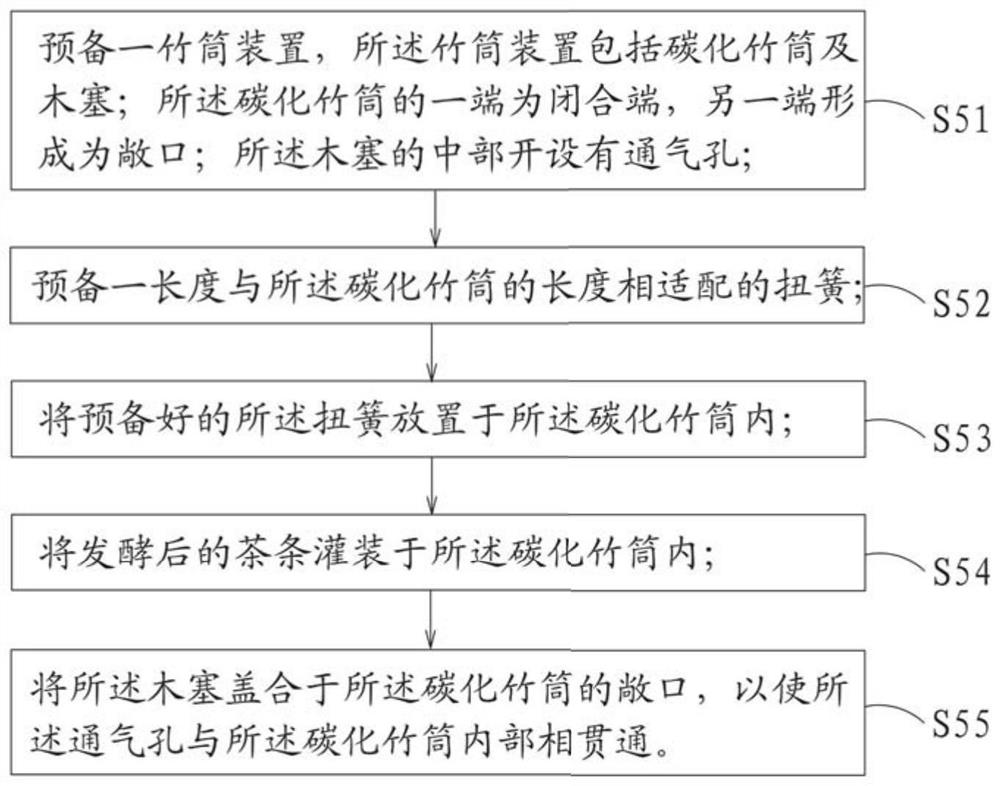

[0053] figure 1 It is a flow chart of the production method for baking and stewing bamboo tube black tea of the present invention; figure 2 is a flowchart of step S1 in the embodiment of the present invention; image 3 is a flowchart of step S5 in the embodiment of the present invention; Figure 4 is a flowchart of step S6 in the embodiment of the present invention; Figure 5 is a flowchart of step S7 in the embodiment of the present invention; Figure 6 It is a schematic plan view of the bamboo tube device described in the embodiment of the present invention;

[0054] combine Figure 1-Figure 6 shown;

[0055] A kind of bamboo tube black tea baking and stewing preparation method provided by the present invention comprises...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com