Ultra-thin fluid absorbent body for disposable hygiene product

A hygienic product and fluid absorption technology, which is applied in the field of absorbers, can solve the problems of accelerated liquid infiltration speed, not easy to increase significantly, and decreased surface dryness, etc., to achieve accelerated liquid infiltration speed, good promotion and application value, and production process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

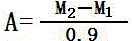

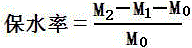

Embodiment 1

[0028] An ultra-thin fluid absorbent for disposable sanitary products, comprising a liquid-permeable layer on the surface of the absorbent body, a liquid-impermeable layer on the bottom surface of the absorbent body, and an absorbent core disposed between the liquid-permeable layer and the liquid-impermeable layer layer. The liquid-permeable layer includes a layer of one or more polymer fibers in polyethylene, polypropylene, polyvinyl chloride, and polyethylene terephthalate through hot air molding, spunbonding molding, and spunlace molding. , melt-blown or air-laying forming one or more of the non-woven materials formed; the absorbent core layer consists of two layers made of polyethylene, polypropylene, polyvinyl chloride, polyethylene terephthalate One or more polymer fibers in alcohol esters are made of non-woven materials formed by one or more of the forming processes of hot air forming, spunbonding forming, spunlace forming, melt blown or air laying forming. A layer of ...

Embodiment 2

[0031] An ultra-thin fluid absorbent for disposable sanitary products, comprising a liquid-permeable layer on the surface of the absorbent body, a liquid-impermeable layer on the bottom surface of the absorbent body, and an absorbent core disposed between the liquid-permeable layer and the liquid-impermeable layer layer. The liquid-permeable layer includes a layer of one or more polymer fibers in polyethylene, polypropylene, polyvinyl chloride, and polyethylene terephthalate through hot air molding, spunbonding molding, and spunlace molding. , melt-blown or air-laying forming one or more of the non-woven materials formed; the absorbent core layer consists of two layers made of polyethylene, polypropylene, polyvinyl chloride, polyethylene terephthalate One or more polymer fibers in alcohol esters are made of non-woven materials formed by one or more of the forming processes of hot air forming, spunbonding forming, spunlace forming, melt blown or air laying forming. A layer of ...

Embodiment 3

[0034] An ultra-thin fluid absorbent for disposable sanitary products, comprising a liquid-permeable layer on the surface of the absorbent body, a liquid-impermeable layer on the bottom surface of the absorbent body, and an absorbent core disposed between the liquid-permeable layer and the liquid-impermeable layer layer. The liquid-permeable layer includes a layer of one or more polymer fibers in polyethylene, polypropylene, polyvinyl chloride, and polyethylene terephthalate through hot air molding, spunbonding molding, and spunlace molding. , melt-blown or air-laying forming one or more of the non-woven materials formed; the absorbent core layer consists of two layers made of polyethylene, polypropylene, polyvinyl chloride, polyethylene terephthalate One or more polymer fibers in alcohol esters are made of non-woven materials formed by one or more of the forming processes of hot air forming, spunbonding forming, spunlace forming, melt blown or air laying forming. A layer of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com