No-sucrose compound lonicera granule and preparation method thereof

A compound honeysuckle and sucrose-free technology, applied in the field of compound honeysuckle granules and their preparation, can solve the problems of inducing diabetes and children's dental caries, sugar-containing granules are easy to deliquescence, and the dosage of auxiliary materials is large, so as to reduce the dosage of auxiliary materials and improve the medicine. Stability, effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

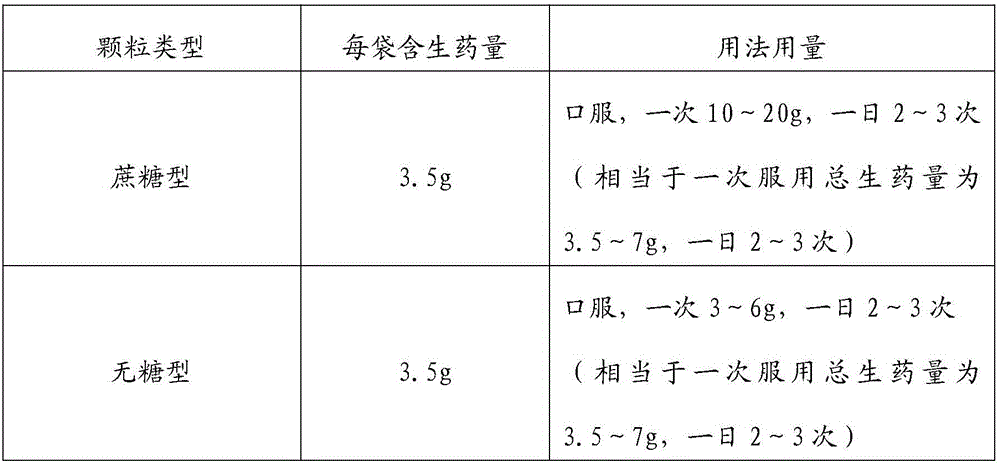

Image

Examples

Embodiment 1

[0029] The sucrose-free compound honeysuckle granules in this example are made of the following raw materials: 450 kg of honeysuckle, 550 kg of forsythia, 150 kg of Scutellaria baicalensis, 4 kg of aspartame and 4 kg of dextrin.

[0030] The preparation method of the above-mentioned sucrose-free compound honeysuckle granule comprises the following steps:

[0031] (1) Preparation of honeysuckle extract: Weigh 450 kg of honeysuckle, add 2.5 times the weight of honeysuckle, soak in water for 25 minutes, heat and decoct to keep a slight boil, collect the distillate of 0.02 times the weight of honeysuckle, filter, and collect the filtrate once; add filter residue Heat and decoct 2.5 times the weight of water, keep boiling slightly for 25 minutes, filter, collect the secondary filtrate, combine the primary filtrate and the secondary filtrate to obtain the combined filtrate; concentrate the combined filtrate under reduced pressure to obtain honeysuckle clear paste; extract the honeysu...

Embodiment 2

[0035] The sucrose-free compound honeysuckle granules of this example are made of the following raw materials: 500 kg of honeysuckle, 500 kg of forsythia, 166.7 kg of scutellaria baicalensis, 3 kg of aspartame and 5 kg of dextrin.

[0036] The preparation method of the above-mentioned sucrose-free compound honeysuckle granule comprises the following steps:

[0037] (1) Preparation of honeysuckle extract: Weigh 500 kg of honeysuckle, add 3 times the weight of honeysuckle, soak in water for 30 minutes, heat and decoct to keep a slight boil, collect the distillate of 0.02 times the weight of honeysuckle, filter, and collect the filtrate once; add filter residue Heat and decoct 3 times the weight of water, keep boiling slightly for 30 minutes, filter, collect the secondary filtrate, combine the primary filtrate and the secondary filtrate to obtain the combined filtrate; concentrate the combined filtrate under reduced pressure to obtain honeysuckle clear paste; extract the honeysuck...

Embodiment 3

[0041] The sucrose-free compound honeysuckle granules of this example are made of the following raw materials: 550 kg of honeysuckle, 450 kg of forsythia, 180 kg of scutellaria baicalensis, 2 kg of aspartame and 6 kg of dextrin.

[0042] The preparation method of the above-mentioned sucrose-free compound honeysuckle granule comprises the following steps:

[0043] (1) Preparation of honeysuckle extract: Weigh 550 kg of honeysuckle, add 3.5 times the weight of honeysuckle, soak in water for 35 minutes, heat and decoct to keep a slight boil, collect the distillate of 0.02 times the weight of honeysuckle, filter, and collect the filtrate once; add filter residue Heat and decoct 3.5 times the weight of water, keep boiling slightly for 35 minutes, filter, collect the secondary filtrate, combine the primary filtrate and the secondary filtrate to obtain the combined filtrate; concentrate the combined filtrate under reduced pressure to obtain honeysuckle clear paste; extract the honeysu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com