Soot blowing system for SCR reactor

A technology of SCR reactor and soot blowing system, which is applied in the direction of cleaning method, cleaning method and utensils, chemical instruments and methods using gas flow, etc., which can solve the problem of inability to blow off the catalyst surface, blockage of catalyst porous channels, and reliable soot blowing system To improve the reliability and stability, shorten the time interval, and avoid blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

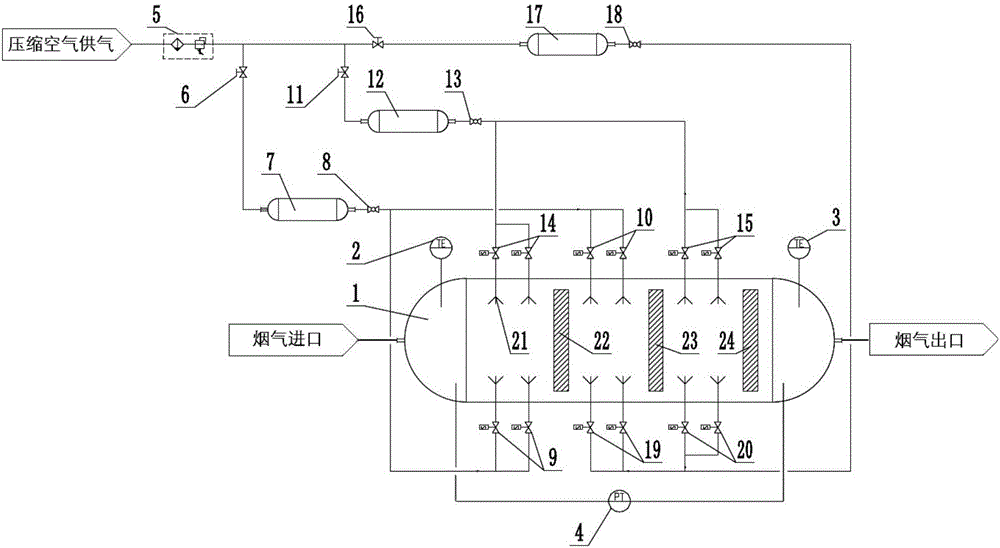

[0022] see figure 1 , the present invention provides a soot blowing system for an SCR reactor, after the waste gas to be treated flows into the SCR reactor 1, passes through three catalyst layers 22, 23 and 24 in sequence, and then flows out. The inlet and outlet of the SCR reactor 1 are provided with temperature sensors 2 and 3 respectively, and a pressure difference sensor 4 is arranged between the inlet and the outlet.

[0023] After the compressed air supply passes through the filter decompression device 5, a branch air supply is used to connect three air cylinders 7, 12 and 17 respectively. Taking one of the branches as an example, an air source shut-off valve 6 is set at the bifurcation of the pipeline near the filter decompression device, and then the compressed air enters the air bottle 7, and an air source ball valve 8 is set at the outlet of the air bottle 7, and then divided into two supply lines. Gas branch, each gas supply branch is divided into two soot blowing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com