Detection method for continuous punching of steel band

A detection method and steel strip technology, applied in the detection field, can solve problems such as inability to sample in the production process, failure to find problems in time, and low detection efficiency, so as to improve detection efficiency and detection accuracy, have good promotion and application prospects, and be easy to operate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

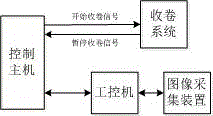

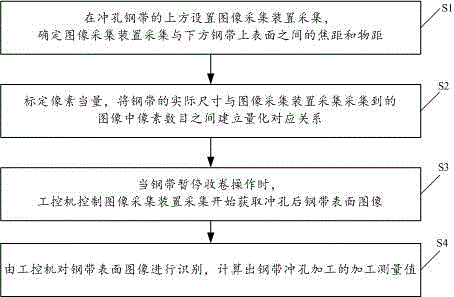

[0027] Such as figure 1 As shown, the steel strip processing production line has a steel strip processing control system, the steel strip processing control system includes a control host and a winding system; and the detection system for the punched steel strip proposed by the present invention mainly includes a connected industrial computer and an image Acquisition device, the industrial computer is connected with the control host through the RS232 interface, and communicates with the control host using the Modbus field bus protocol.

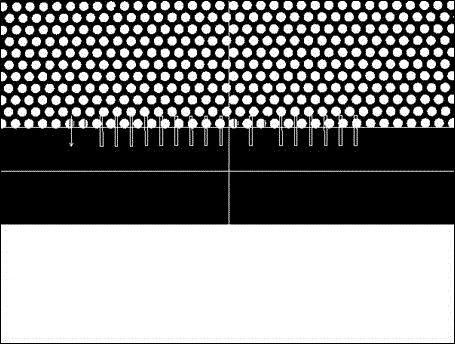

[0028] The winding system is under the control of the control host. During the punching process, every time a section of steel coil is punched, it will be wound again, and the winding will stop when the winding reaches a certain level. When the winding system detects the winding signal, the winding system starts to work and winds the steel strip. At this time, the industrial computer controls the image acquisition device to stop image acquisit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com