Drilling machine tool

A drilling mechanism and machine tool technology, applied in the direction of boring/drilling, drilling/drilling equipment, metal processing machinery parts, etc., to achieve the effects of improving efficiency, saving wasted time, and being easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

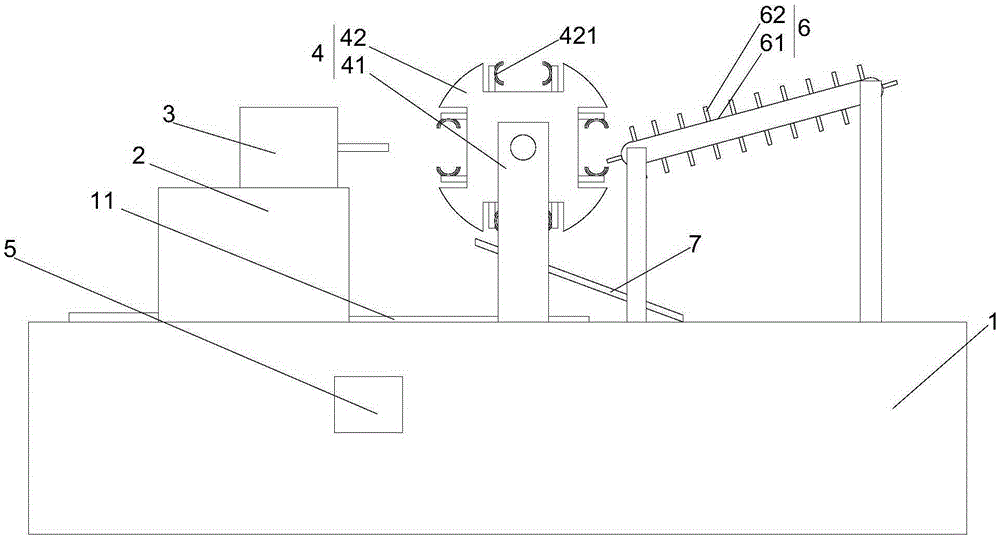

[0019] refer to figure 1 As shown, a kind of drilling machine tool that the present invention proposes comprises frame 1, moving mechanism 2, drilling mechanism 3 and fixing mechanism 4;

[0020] Slide rail 11 is installed on the frame 1, mobile mechanism 2 is movably installed on the slide rail 11 and is positioned at frame 1 side, and drilling mechanism 3 is installed on the mobile mechanism 2, and fixing mechanism 4 is installed on the frame 1 and Located on the side opposite to the mobile mechanism 2;

[0021] The fixing mechanism 4 includes a support column 41 and a clamping device 42. The clamping device 42 is rotatably installed on the support column 41. The clamping device 42 is provided with four uniformly distributed fixing clips 421 around its axial direction. Clamp 421 comprises a set of clamping plates that can move relatively,

[0022] In this embodiment, when the clamping device 42 does not rotate with the support column 41 , the four fixing clamps 421 are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com