Quick repair welding machine for anode steel claw

A technology of anode steel claws and welding machines, which is applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of restricting technological innovation and development of enterprises, short service life of steel claws, and large manual mechanical consumption, etc., to achieve manual consumption Low cost, long service life and fast welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

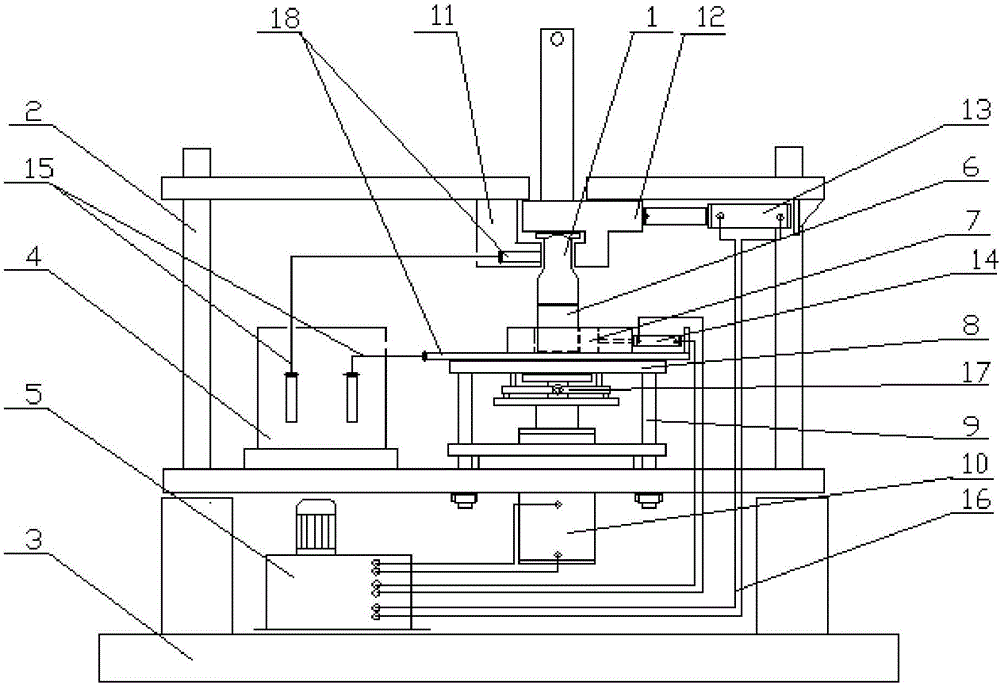

[0025] The present invention will be further described below in conjunction with accompanying drawing:

[0026] Such as figure 1 As shown: the present invention includes a welding machine main frame 2, a welding machine base 3, a transformer 4, a hydraulic station 5, a steel bar clamping device 7, a sliding limit plate 8, a sliding limit rod 9, a main hydraulic cylinder 10, and a fixing clip Tightening device 11, sliding clamping device 12, sliding clamping device hydraulic cylinder 13, steel bar clamping device hydraulic cylinder 14, copper wire 15, high pressure oil pipe 16, welding control device 17 and electrode contact block 18, the welding machine host The frame 2 is located on the welding machine base 3, the fixed clamping device 11 is arranged on the welding machine main frame 2, the sliding clamping device 12 is located on the opposite side of the fixed clamping device 11, and is connected with The sliding clamping device hydraulic cylinder 13 is connected, the steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com