Patents

Literature

34results about How to "Has the value of promotion and use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

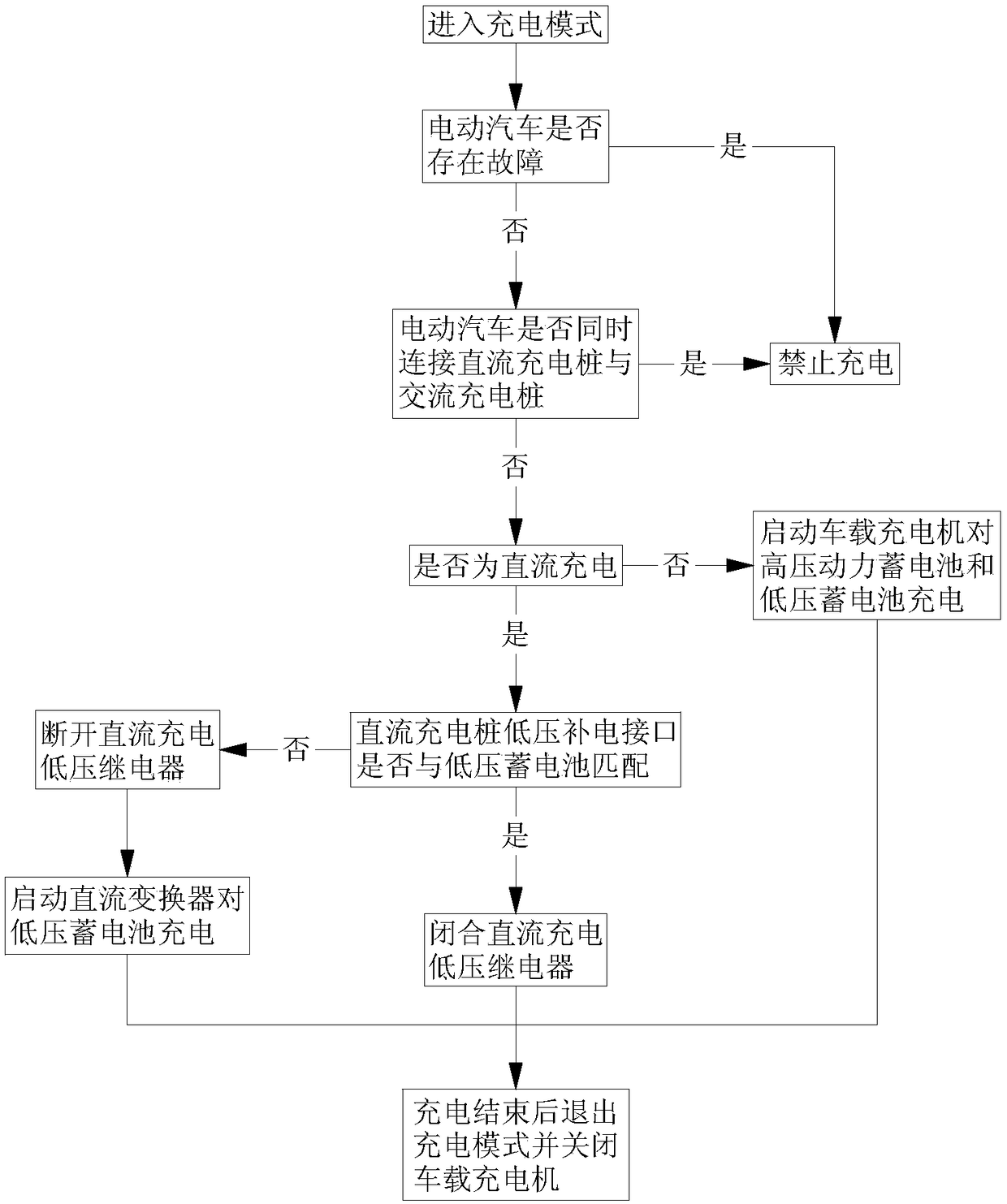

Charging management control method for electric automobile

ActiveCN108773281AWill not cause power lossHigh degree of intelligenceElectric vehicle charging technologyVehicular energy storageLow voltageHigh voltage

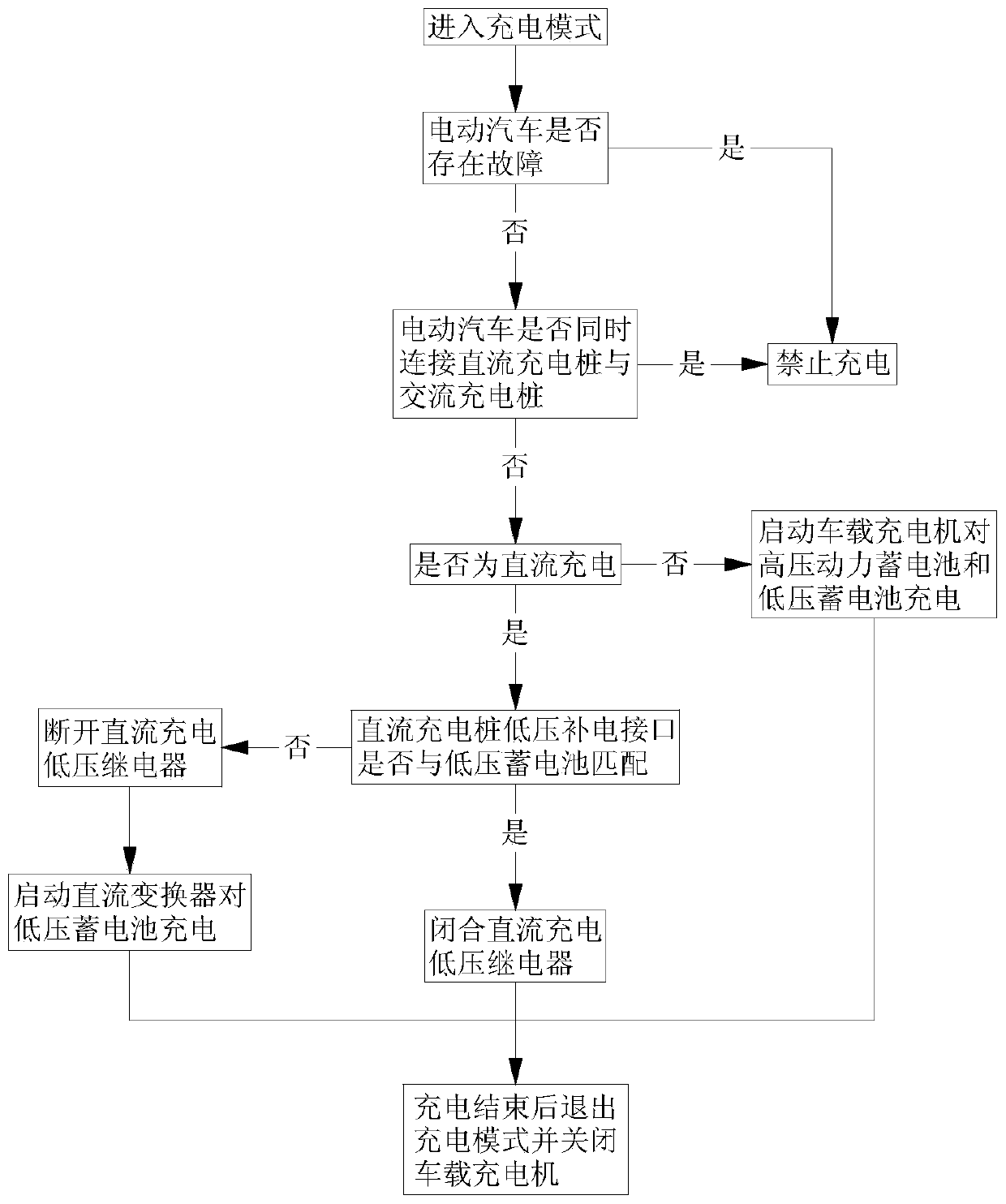

The invention relates to the field of electric control of electric automobiles, and aims to provide a charging management control method for an electric automobile capable of effectively avoiding lackof electricity of a low voltage storage battery. The technical scheme is that the charging management control method for the electric automobile includes the following steps: a vehicle controller automatically enters a charging mode; a BMS judges a type of a charging pile; when the charging pile is a direct current charging pile, a low voltage supplementary electricity voltage of the direct current charging pile is measured; when the low voltage supplementary electricity voltage of the direct current charging pile is identical to a rated voltage of the low voltage storage battery of the electric mobile, the low voltage battery is directly charged by a low voltage supplementary electricity interface of the direct current charging pile; and when the low voltage supplementary electricity voltage of the direct current charging pile is different from the rated voltage of the low voltage storage battery of the electric mobile, a direct current converter of the electric automobile is startedand converts high-voltage power of a high-voltage power storage battery into low-voltage power corresponding to the low-voltage storage battery, and electricity is supplemented to the low-voltage storage battery. The charging management control method enables the lack of electricity of the low voltage storage battery to be avoided.

Owner:CHENGDU RAJA NEW ENERGY AUTOMOTIVE TECH CO LTD

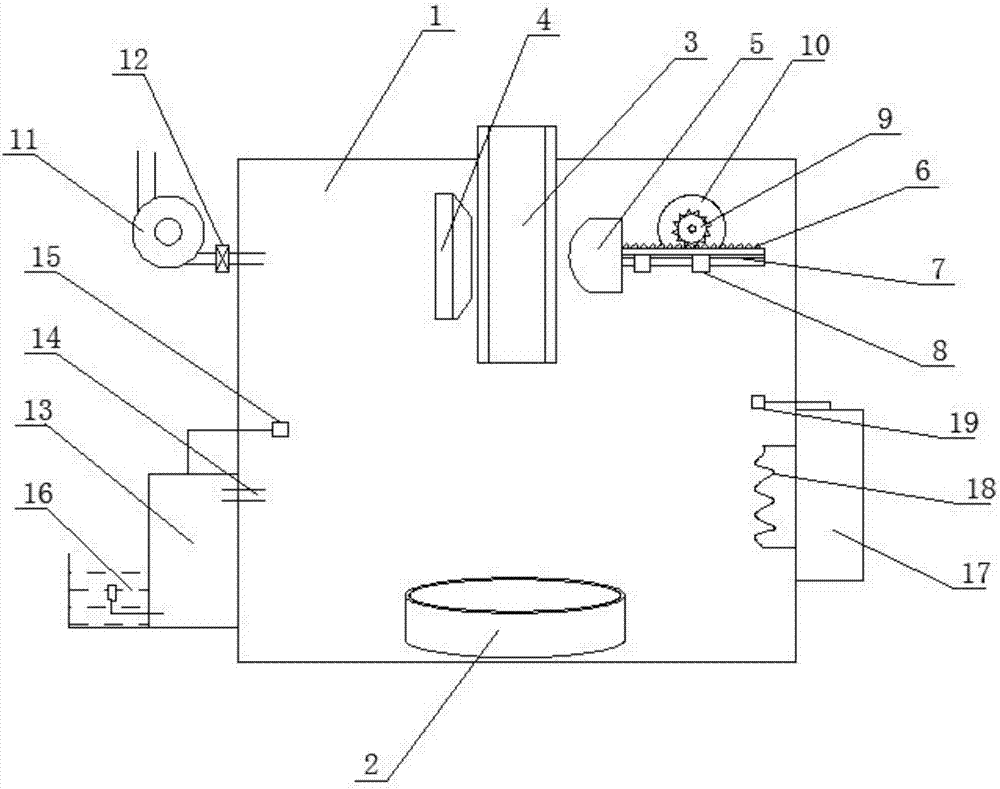

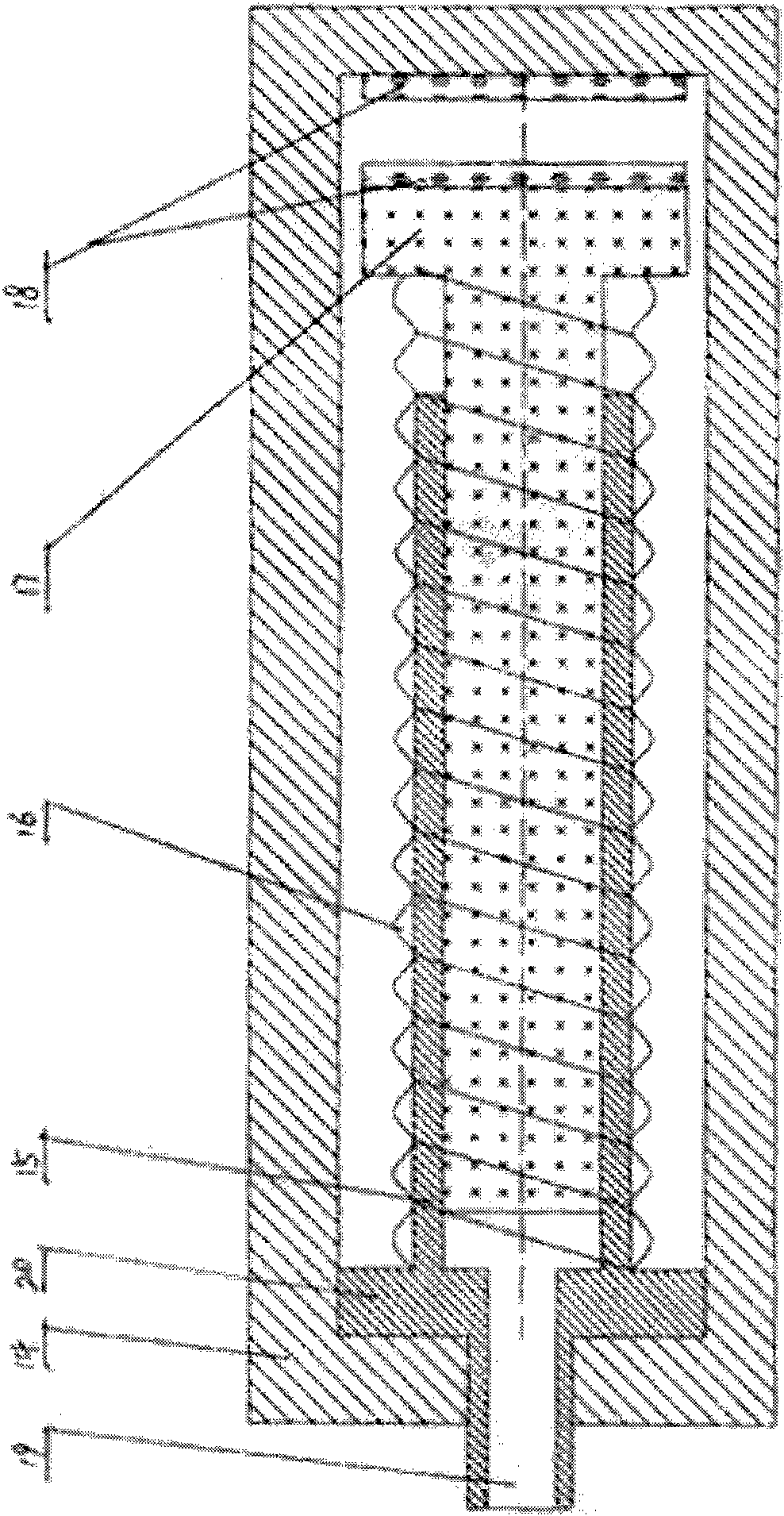

Anti-pollution type bacterial culture device for microbial experiment

InactiveCN106867895AAvoid pollutionEasy to operateBioreactor/fermenter combinationsBiological substance pretreatmentsBiologyVacuum pump

The invention discloses an anti-pollution type bacterial culture device for a microbial experiment. The culture device comprises a culture box, a culture dish, a rubber tube, a stop base, a stop push rod, a rack bar, a chute, a sliding rail, a gear, a motor, a vacuum pump and a one-way valve, wherein the rubber tube is arranged on the upper part of the culture box and communicated with the interior and exterior of the culture box; the stop base is arranged on one side of the rubber tube; the stop push rod is arranged on the other side of the rubber tube and fixedly connected with one end of the rack bar; the chute is formed in the rack bar and positioned in the sliding rail; the rack bar is connected with the gear; the gear is connected with the motor; and the vacuum pump is connected with the culture box through the one-way valve. Medicines are added into the culture dish in the middle of the rubber tube by an injector, and the rack bar is driven by the motor after addition completion, so that the rubber tube is extruded onto the stop base by the stop push rod so as to be closed. Then, the rubber tube is vacuumized by the vacuum pump, pollution in the culture box is avoided, the operation is convenient, the culture result is kept accurate, and the culture device has high popularization and application value.

Owner:宗春辉

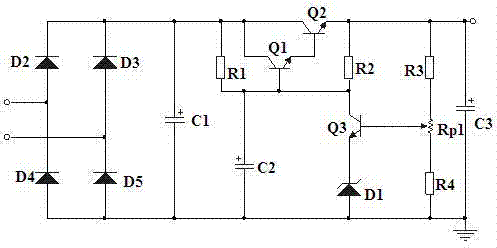

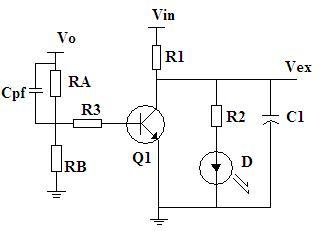

Series voltage-stabilizing circuit used for small power type power circuit

InactiveCN102412743ASimple structureImprove performanceAc-dc conversion without reversalApparatus without intermediate ac conversionElectrical resistance and conductancePower circuits

The invention discloses a series voltage-stabilizing circuit used for a small power type power circuit. The series voltage-stabilizing circuit comprises a voltage-stabilizing bridge circuit, wherein one output end of the voltage-stabilizing bridge circuit is connected with a collector of a Darlington tube; an emitter of the Darlington tube is led out to serve as the output end of the series voltage-stabilizing circuit; the other output end of the voltage-stabilizing bridge circuit is earthed; a base of the Darlington tube is connected with the collector by a first resistor and is connected with the emitter by a second resistor; the base of the Darlington tube and the connection end of the first resistor are connected to the earth end of the voltage-stabilizing bridge circuit; the base of the Darlington tube and the connection end of the second resistor are connected to a collector of a third triode; an emitter of the third triode is connected to the earth end of the voltage-stabilizing bridge circuit by a voltage-stabilizing tube; a base of the third triode is connected with the sliding pin end of an adjustable resistor; and the adjustable resistor is connected at the two output ends of the voltage-stabilizing bridge circuit by two fixed pin ends of the adjustable resistor. The series voltage-stabilizing circuit has a simple structure, stable and reliable properties and popularization and application values.

Owner:SUZHOU HEXINMEI ELECTRONICS SCI & TECH CO LTD

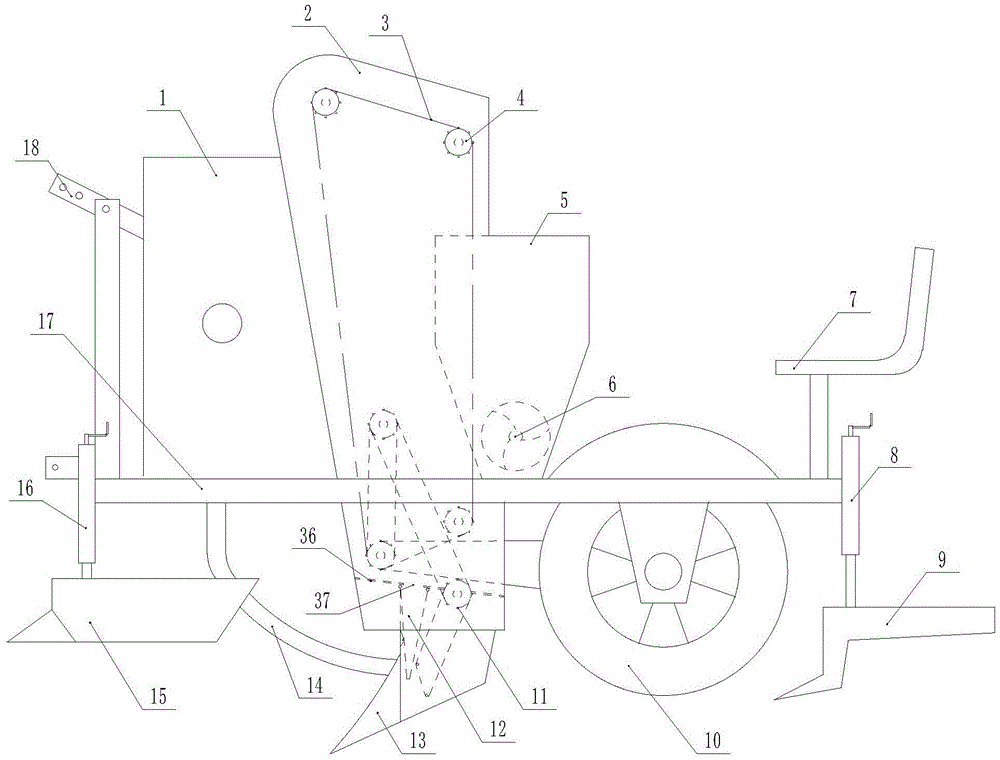

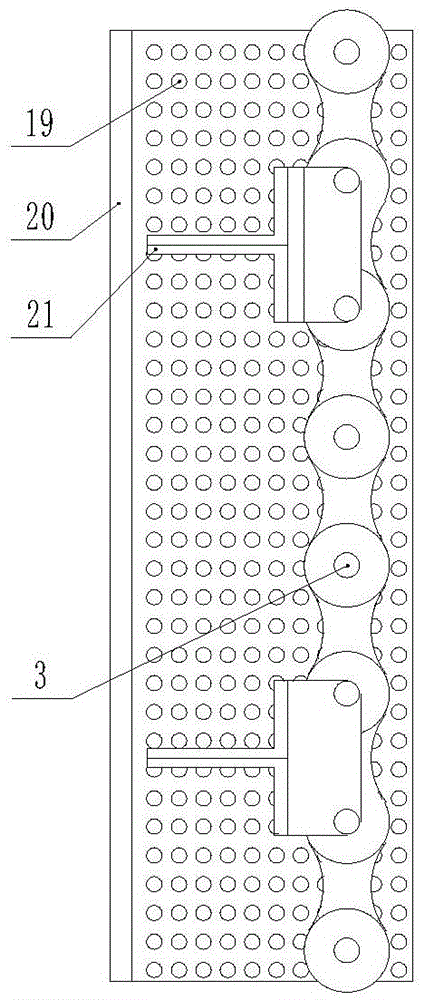

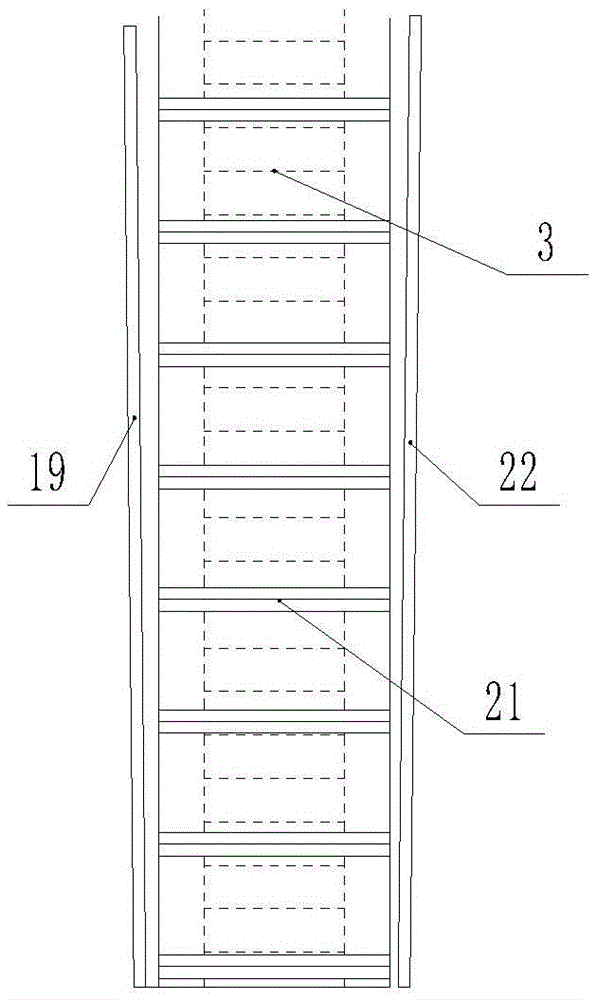

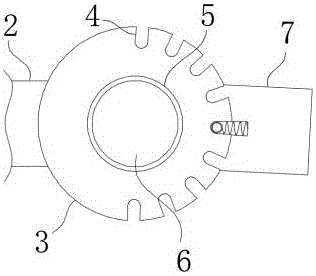

Garlic sowing machine

ActiveCN105580545AGuaranteed uprightIncrease success rateFertiliser distributersPotato plantersSeederGear wheel

The invention discloses a garlic sowing machine and belongs to the field of agriculture machinery. The garlic sowing machine is applied to mechanized garlic sowing and comprises a rack, wherein the rack is equipped with travelling wheels and a drawing mechanism, a sowing box, an aligning mechanism and a garlic clove furrow opener are further mounted on the rack, the aligning mechanism comprises transmission gears and a conveying chain, and support plates are arranged on the conveying chain; an aligning baffle plate A and an aligning baffle plate B with porous structures are arranged on two sides in the downlink direction of the conveying chain respectively and arranged on a chain baffle plate, space between the aligning baffle plate A and the aligning baffle plate B is gradually reduced, and the aligning baffle plate A, the aligning baffle plate B and the chain baffle plate constitute a channel allowing the conveying chain and the support plates to move; a sowing baffle plate is arranged below the aligning mechanism, and sowing ports are formed in the sowing baffle plate. With the adoption of the technical scheme, the defects that the planting requirement cannot be met due to the fact that the garlic sowing machine cannot guarantee that the garlic clove bulbils are upward during sowing in the prior art is overcome.

Owner:临沂华翔鑫农业机械科技有限公司

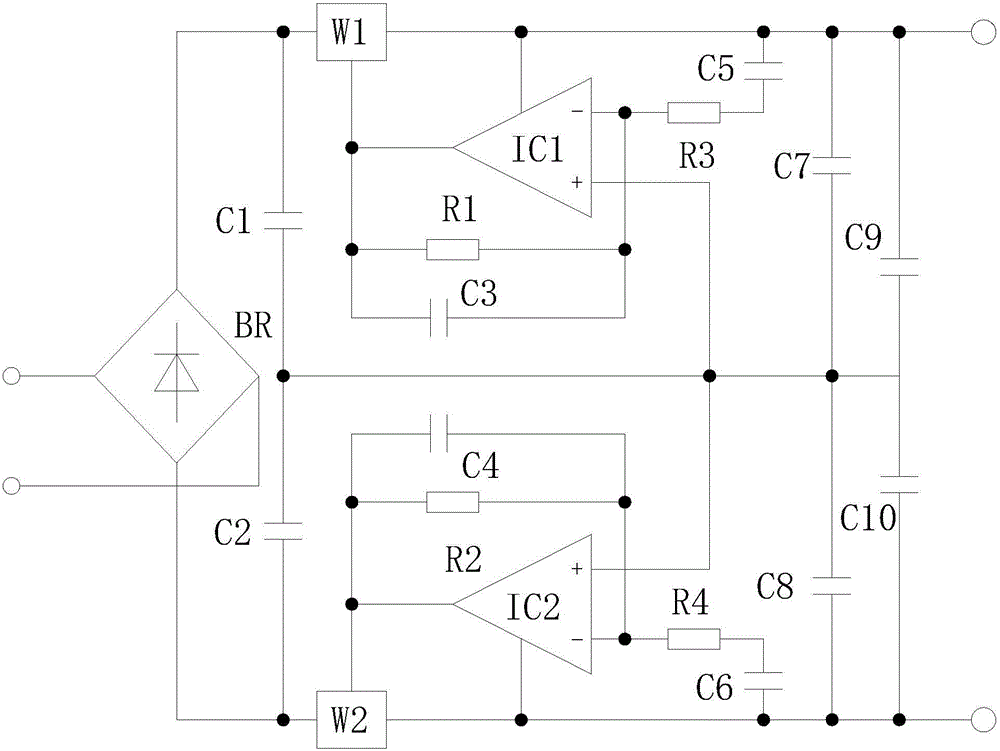

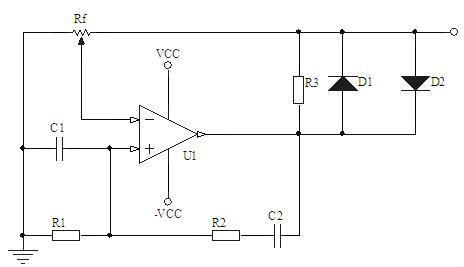

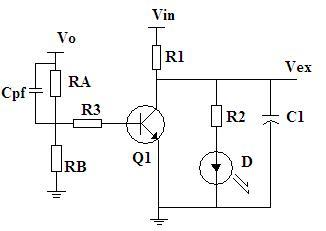

Special bipolar linear voltage-stabilized source for software testing host

InactiveCN104679081AGuaranteed accuracyHas the value of promotion and useElectric variable regulationCapacitanceAlternating current

The invention discloses a special bipolar linear voltage-stabilized source for a software testing host. The special bipolar linear voltage-stabilized source for the software testing host comprises a first resistor, a second resistor, a third resistor, a fourth resistor, a first capacitor, a second capacitor, a third capacitor, a fourth capacitor, a fifth capacitor, a sixth capacitor, a seventh capacitor, an eighth capacitor, a ninth capacitor, a tenth capacitor, a first three terminal regulator, a second three terminal regulator, a first amplifier, a second amplifier and a bridge rectifier circuit, the alternating current input end of the bridge rectifier circuit is connected with the electric supply, and the anode output end of the bridge rectifier circuit is respectively connected with the first end of the first capacitor and the input end of the first three terminal regulator. The special bipolar linear voltage-stabilized source for the software testing host uses two three terminal regulators to form a simple and practical symmetrical positive / negative voltage-stabilized source, the testing host is not influenced when the electric supply is changed suddenly, and the testing precision is guaranteed; the special bipolar linear voltage-stabilized source for the software testing host is simple, practical, stable, effective and broad in popularization and use value.

Owner:CHENGDU SIMATE SCI & TECH

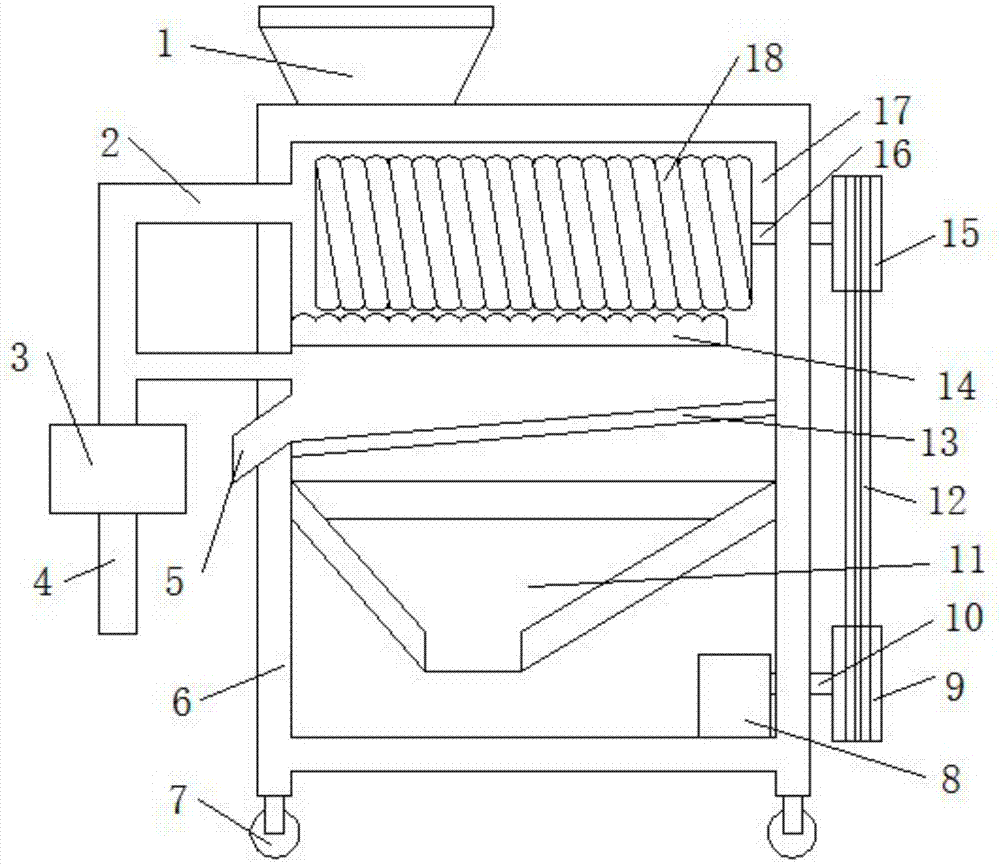

Dust-free rice beating machine

InactiveCN106914298APreserve nutritional valueFree from destructionGrain huskingGrain polishingNutritive valuesDrive wheel

The invention discloses a dust-free rice beating machine. The dust-free rice beating machine comprises a machine frame, a motor, an output shaft, a driving wheel, a driven wheel, a rotating shaft, a stone roll, a roll base and a hulling chamber. A feeding inlet is installed in the top end of the machine frame. The hulling chamber is arranged on the upper portion of the machine frame. The motor is installed on the lower portion of the machine frame. The right end of the motor is connected with the output shaft. The output shaft is connected with the driving wheel. The driving wheel is connected with the driven wheel through a belt, and the driven wheel is connected with the rotating shaft. The rotating shaft penetrates through the machine frame to enter the hulling chamber, and is further connected with the stone roll inside the hulling chamber. The stone roll is provided with arc-shaped protrusions and the roll base is installed inside the hulling chamber. The upper surface of the roll base is also provided with arc-shaped protrusions. A rice grain outlet is formed in the lower end of the hulling chamber. A stalk outlet is formed in the right end of the hulling chamber. According to the dust-free rice beating machine, the stone roll and the roll base are used for milling rice, rice skin of the milled rice cannot be destroyed, and original nutritive value of the rice is effectively stored; and moreover, manufacturing cost is low and application and popularization value can be achieved.

Owner:CHONGQING KUNQI BUILDING MATERIALS CO LTD

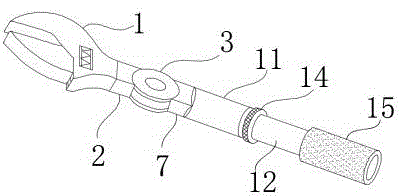

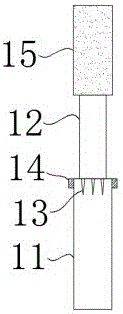

Labor-saving wrench for construction site

InactiveCN106078583AAdjustable lengthAdjustable angleSpannersWrenchesArchitectural engineeringScrew thread

The invention discloses a labor-saving wrench for a construction site. The labor-saving wrench comprises a wrench body, a positioning device and an extension device, wherein the wrench body is connected with the extension device by virtue of the positioning device, the positioning device comprises a first connecting rod, one end of the first connecting rod is fixedly connected with the wrench body, the other end of the first connecting rod is fixedly connected with a positioning disc, a positioning groove is formed in the outer side of the positioning disc, a positioning rod groove is formed in a second connecting rod, a reset spring is arranged on one end, which is far from of a rotating shaft, of the positioning rod groove, and the outer side of the reset spring is fixedly connected with a positioning rod; the extension device comprises an extension sleeve, an extension rod sleeves the interior of the extension sleeve, a V-shaped groove is formed in an opening of the extension sleeve, and a locking ring is in threaded connection to the outer side of the extension sleeve. The labor-saving wrench has the advantages of simple structure, labor saving and wide application range and has popularization and application values, and the self length and the screwing angle can be adjusted.

Owner:TIANJIN SENRAN ENG COST CONSULTING

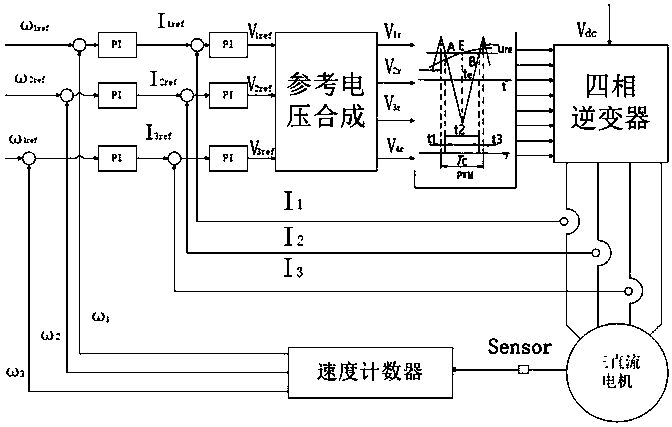

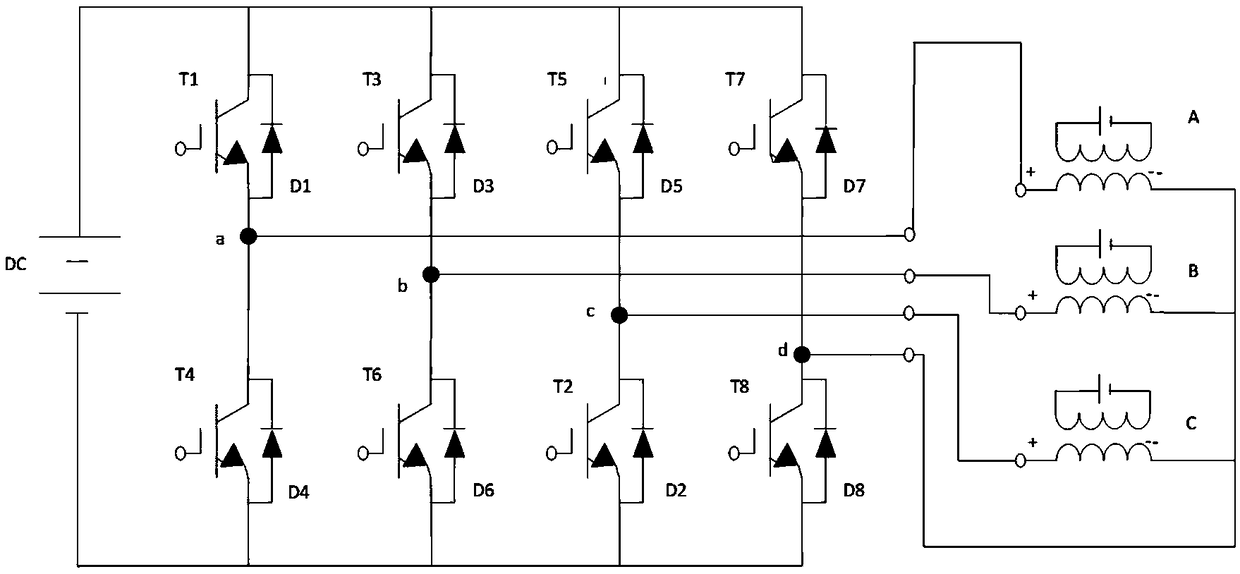

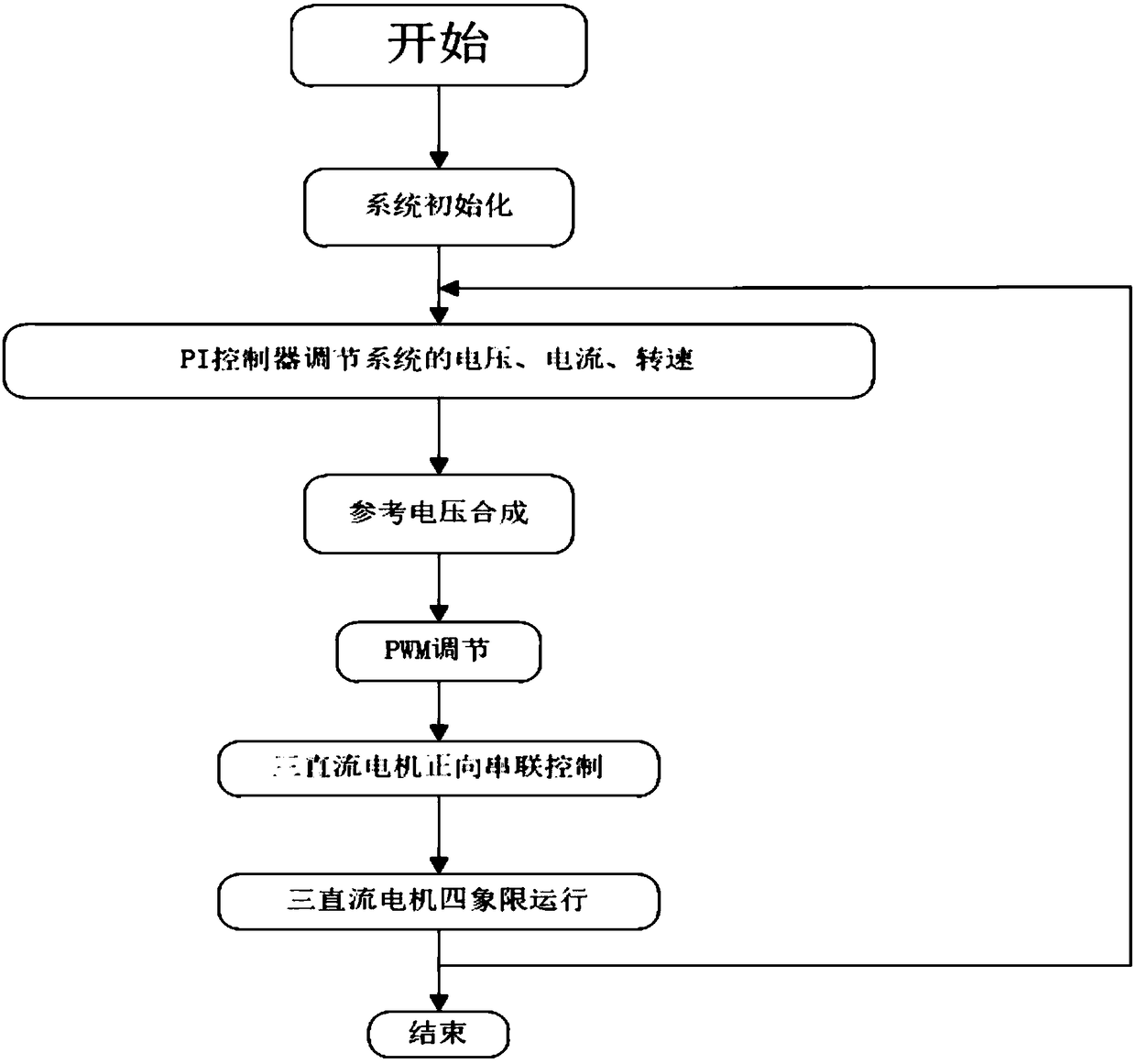

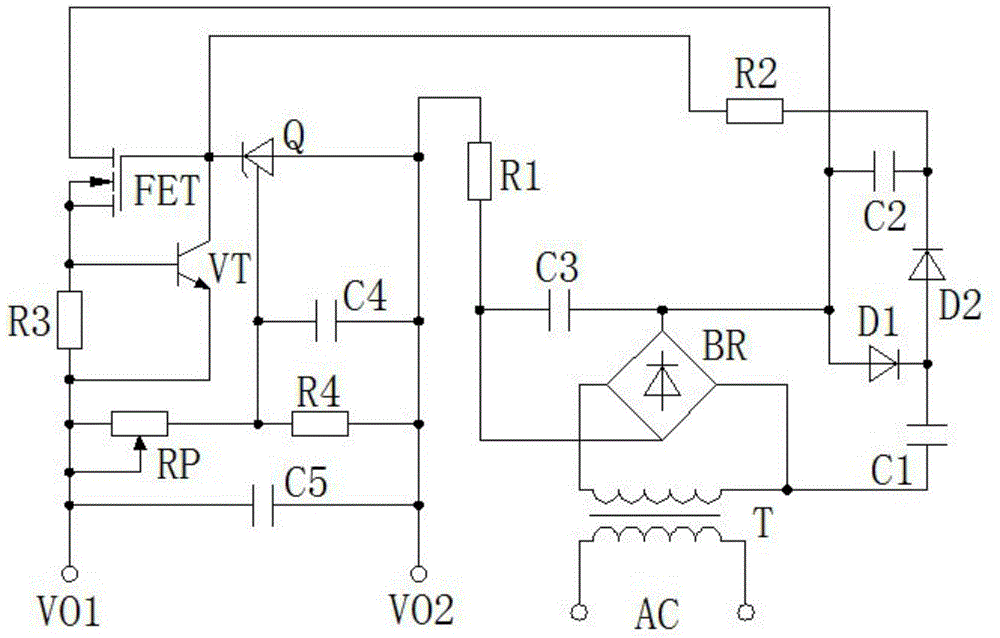

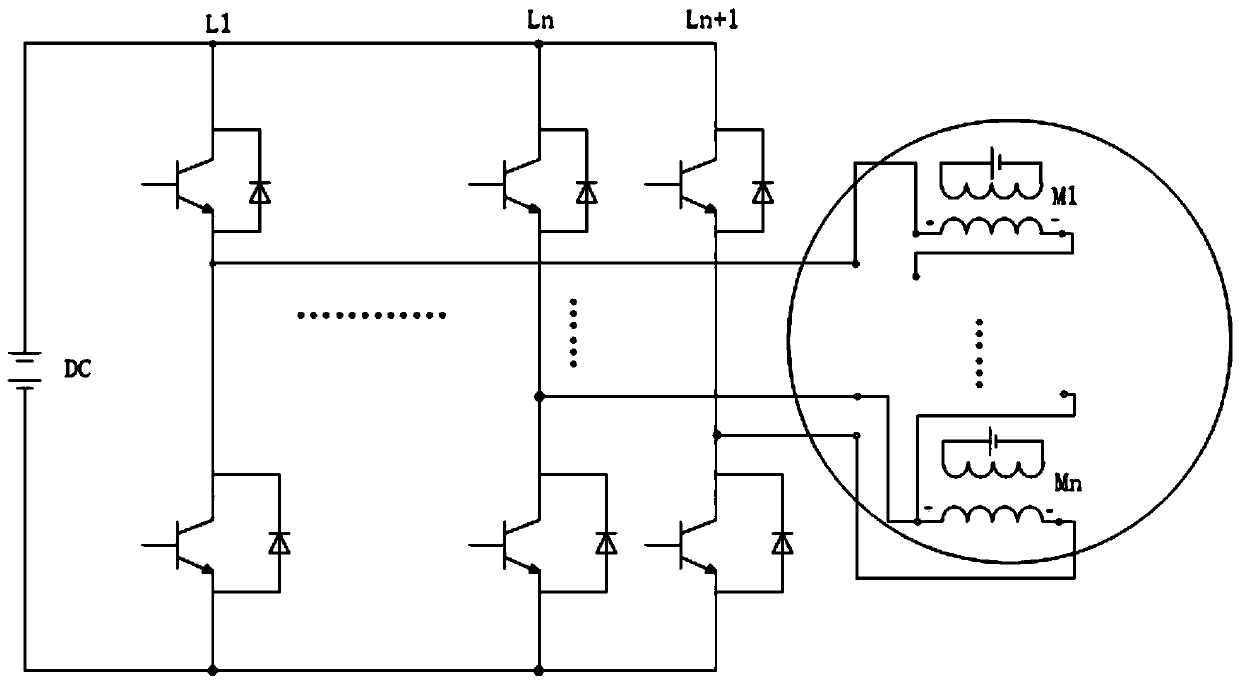

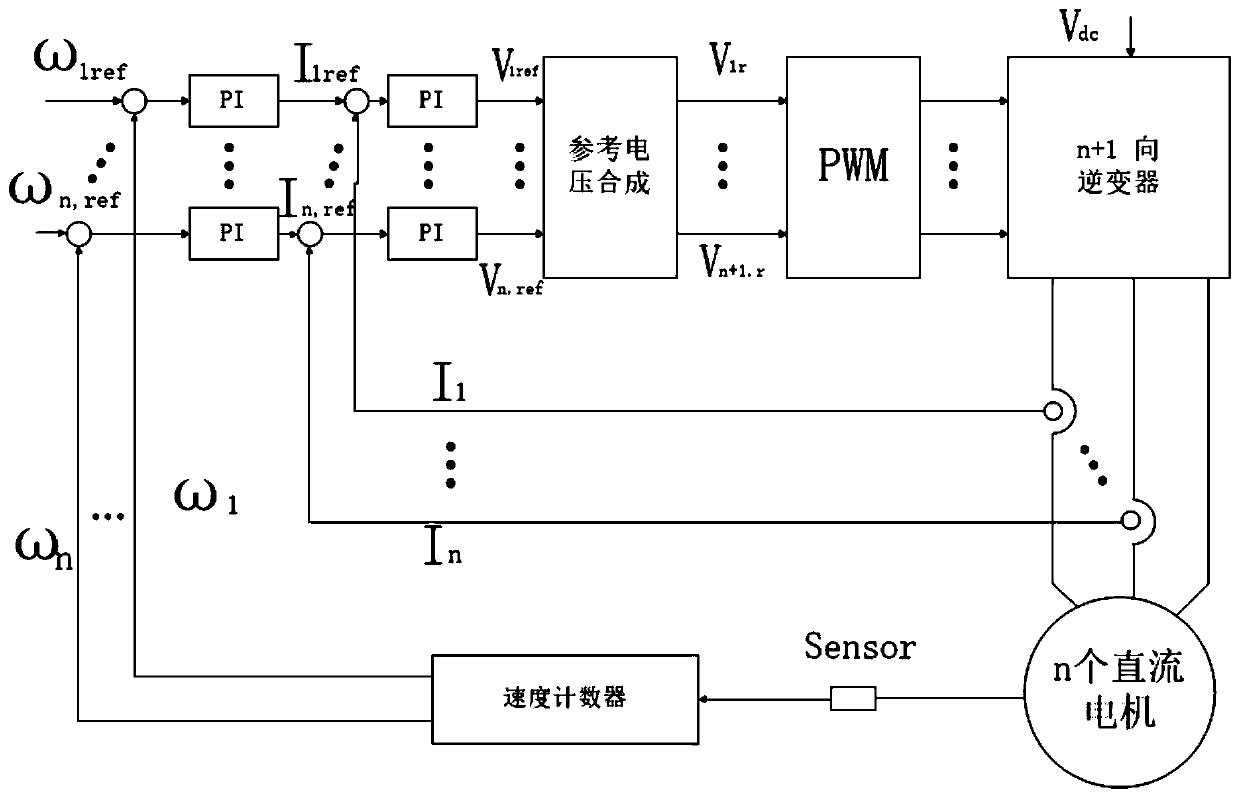

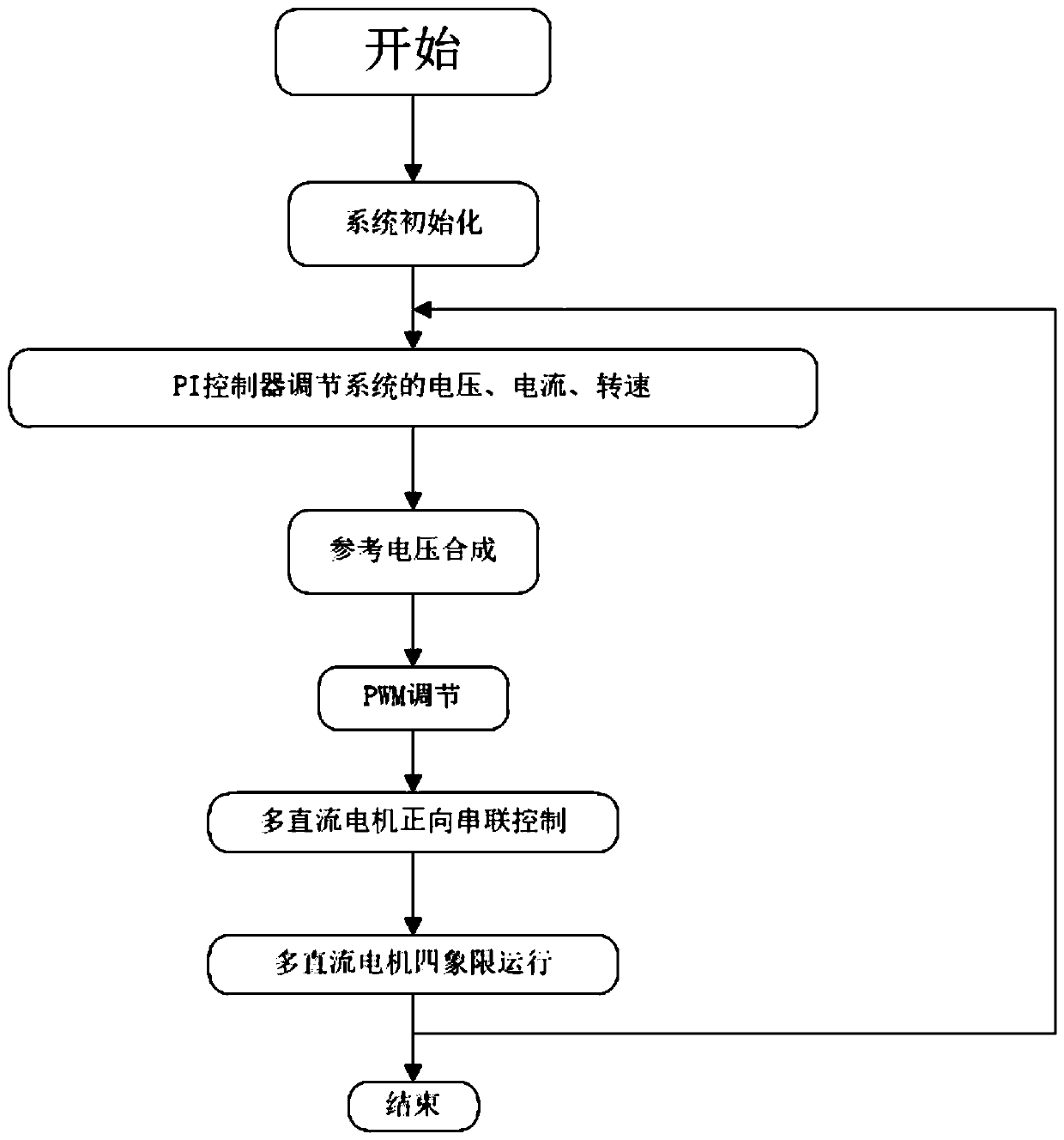

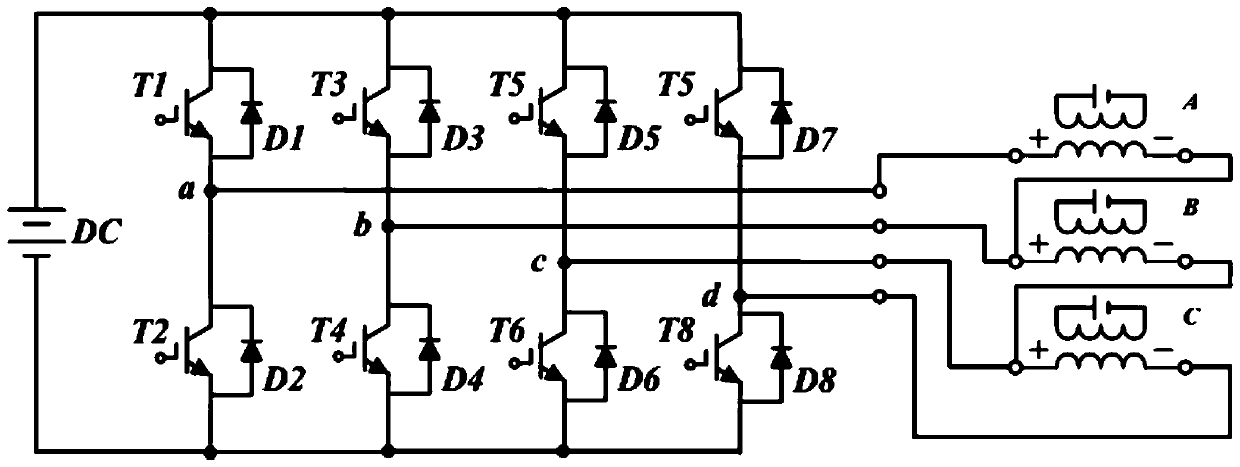

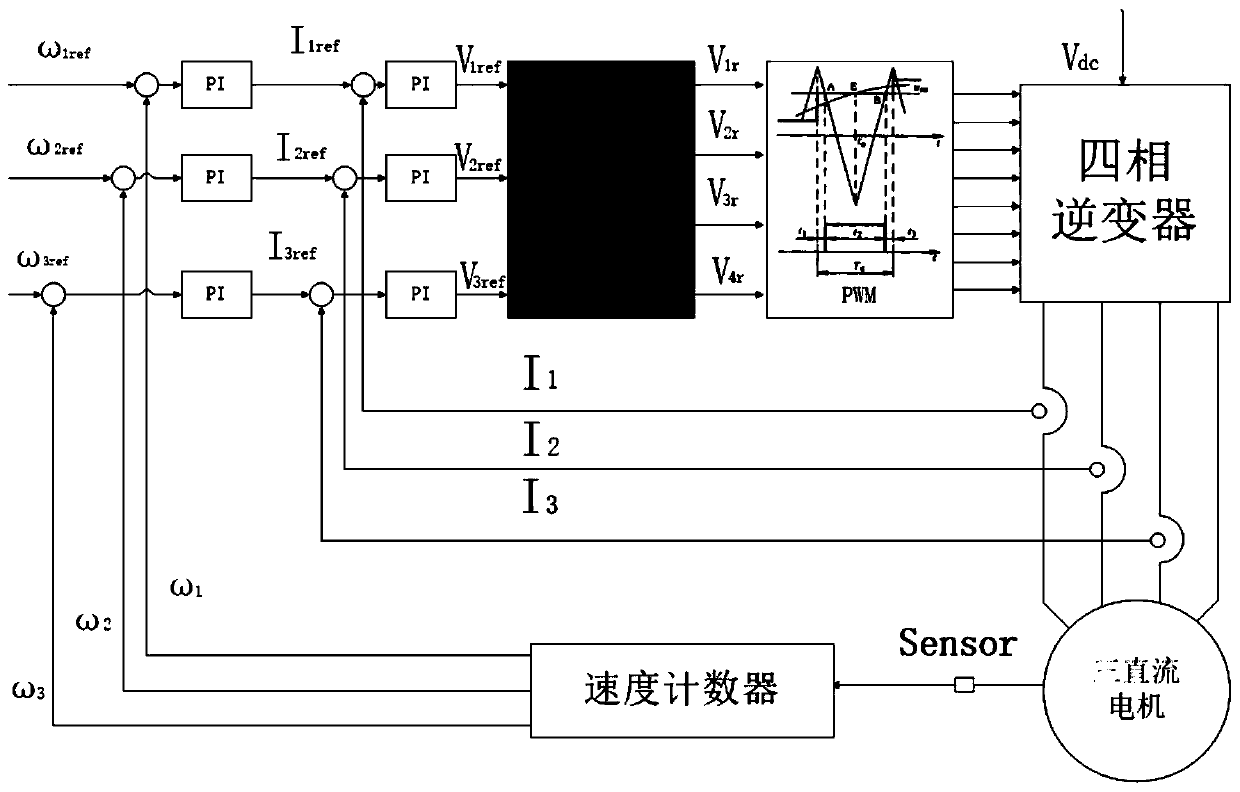

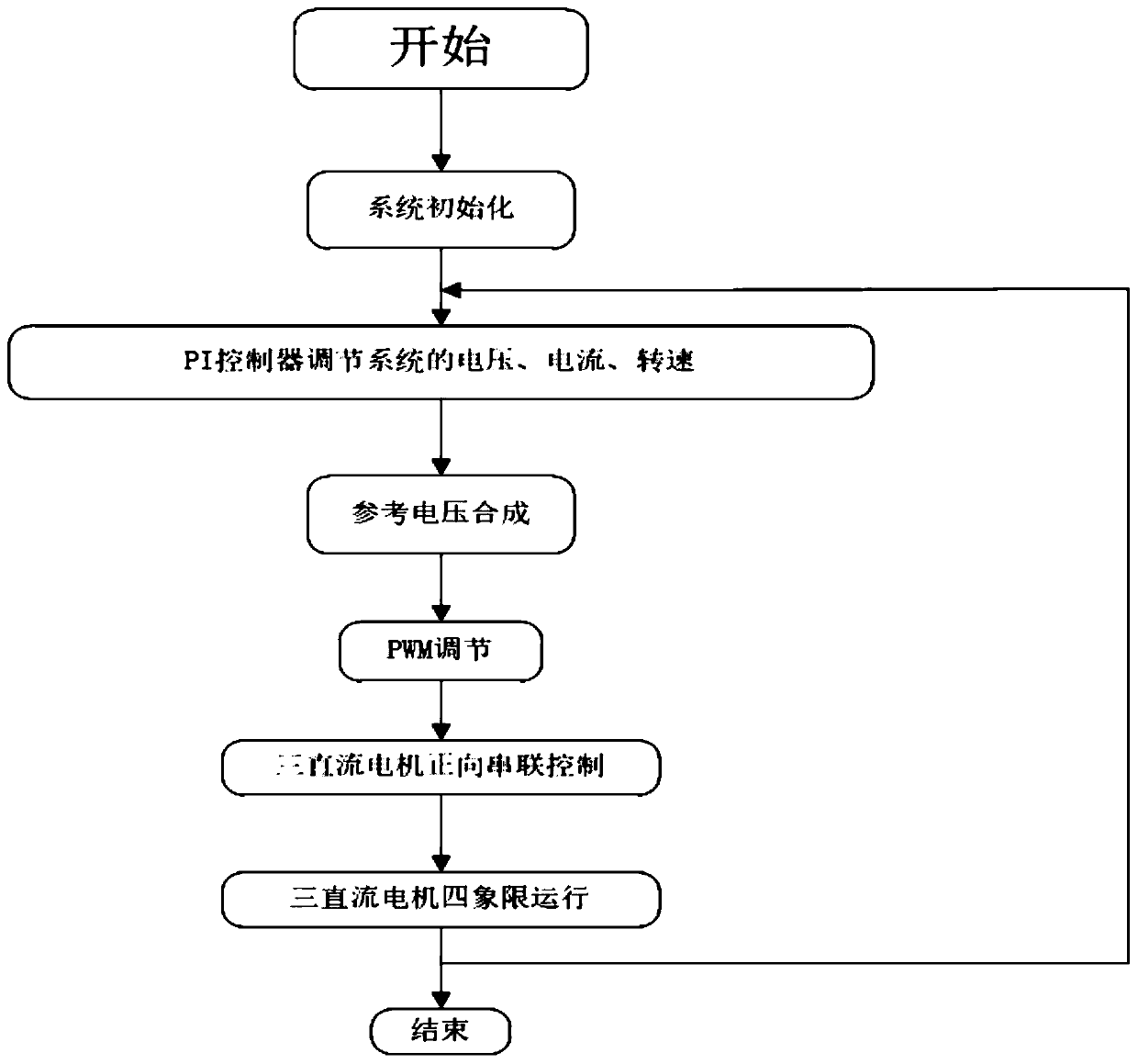

Control system and method with three direct-current motors in forward-direction serial connection

ActiveCN108809157AThe system structure is simple and clearEasy to controlElectric motor speed/torque regulationVoltage referencePower flow

The invention discloses a control system and method with three direct-current motors in forward-direction serial connection. The system is characterized in that eight IGBT modules form four bridge arms in a two-two serial connection manner, the four bridge arms are parallelly connected to the positive electrode and the negative electrode of a direct-current power supply, the three direct-current motors in forward-direction serial connection are serially connected with the four bridge arms, the three direct-current motors are connected with a reference voltage synthesizer sequentially through aspeed sensor, a current sensor, a speed adjusting module and a secondary PI controller, the reference voltage synthesizer is connected with a four-phase inverter through a PWM pulse generating unit,the four-phase inverter is connected with the reference voltage synthesizer through a current adjusting module and a primary PI controller, the four-phase inverter is connected to the PWM pulse generating unit through the reference voltage synthesizer, and pulse control signals generated by the PWM pulse generating unit controls the on and off of the eight IGBT modules to drive the three direct-current motors to operate. The control system is few in used circuit components, simple in structure, stable and reliable in performance and worthy of popularization and application.

Owner:TIANJIN SAIXIANG TECH

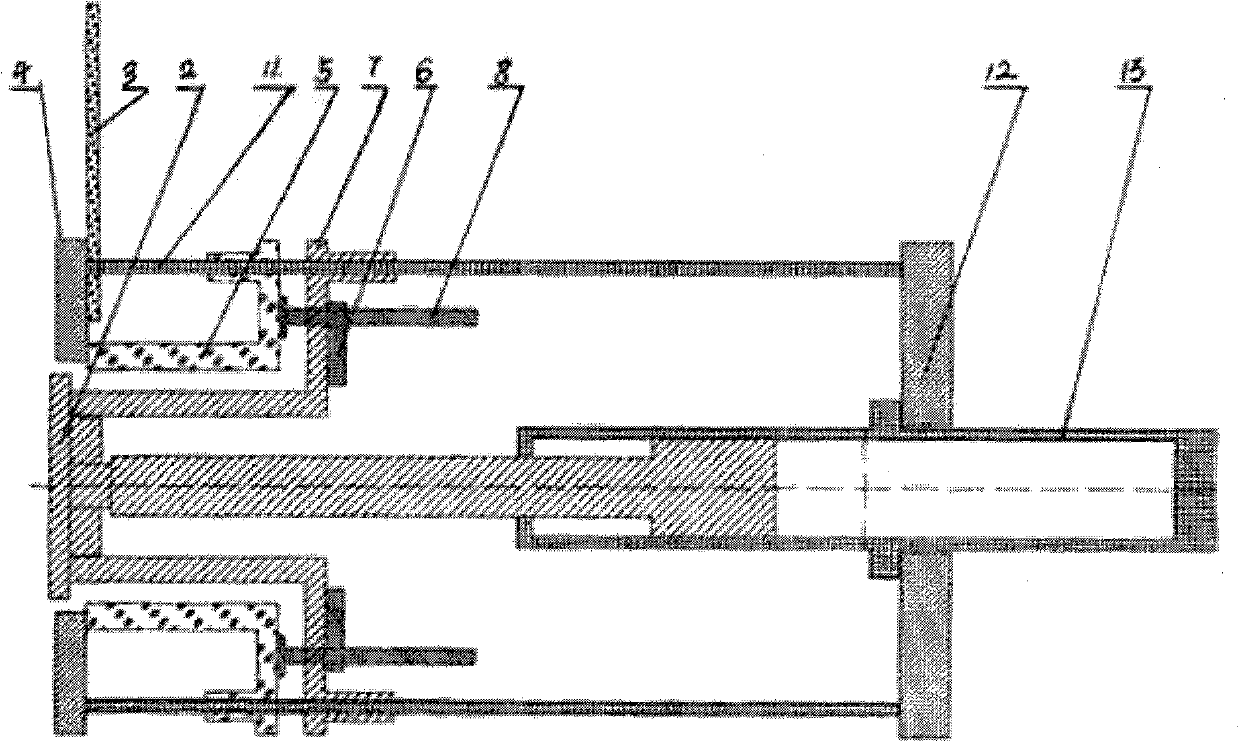

Quick repair welding machine for anode steel claw

InactiveCN106624260AExtended service lifeImprove conductivityArc welding apparatusHydraulic cylinderCopper conductor

The invention discloses a quick repair welding machine for an anode steel claw. The quick repair welding machine comprises a welding machine main rack, a welding machine pedestal, a transformer, a hydraulic station, a steel stick clamping device, a sliding limiting plate, a sliding limiting rod, a main hydraulic cylinder, a fixed clamping device, a sliding clamping device, a sliding clamping device hydraulic cylinder, a steel stick clamping device hydraulic cylinder, copper conductors, a high-pressure oil pipe, a welding control device and electrode contact blocks, wherein the steel stick clamping device clamps a steel stick; the fixed clamping device and the sliding clamping device clamp the anode steel claw to be repaired; and after the quick repair welding machine is electrified, the main hydraulic cylinder carries out contact welding on the steel stick and the anode steel claw to be repaired. Compared with the prior art, the quick repair welding machine for the anode steel claw hasthe advantages of high welding speed, long service life of the repaired steel claw, high conductivity, low material consumption and low manual consumption; the working efficiency is improved, and theuse effect is good; and the quick repair welding machine has popularization and use value.

Owner:白银中科威远环境科技设备有限公司

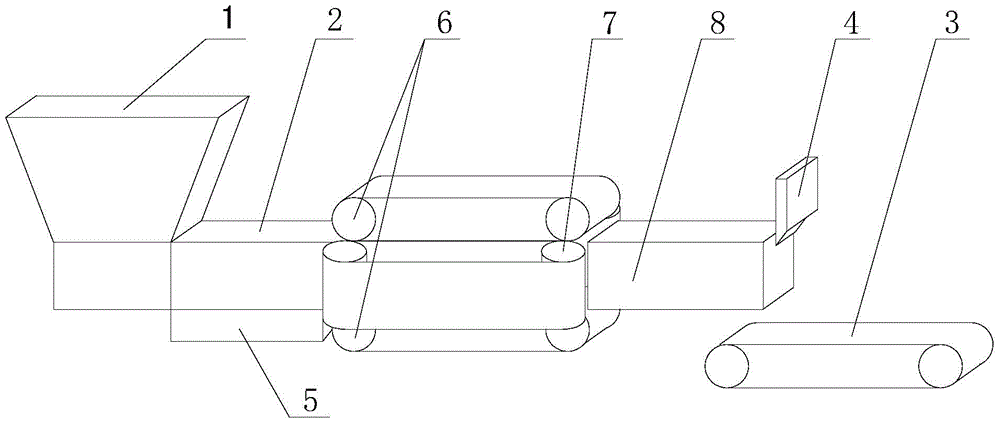

Chocolate polishing and shaping device

The invention discloses a chocolate polishing and shaping device. The chocolate polishing and shaping device comprises a feeder, a feeding channel, a discharge channel, an upper and lower surface polishing and shaping device, a left and right surface polishing and shaping device and a cutter, wherein the lower end of the feeder is connected with one end of the feeding channel, the other end of the feeding channel is in contact with the first ends of the upper and lower surface polishing and shaping device and the left and right surface polishing and shaping device, a polishing belt of the upper and lower surface polishing and shaping device is sequentially in contact with a polishing belt of the left and right surface polishing and shaping device, the first end of the discharge channel is in contact with the second ends of the upper and lower surface polishing and shaping device and the left and right surface polishing and shaping device, and the cutter is arranged at the second end of the discharge channel. The chocolate polishing and shaping device is used for simultaneously polishing the left and right surfaces and the upper and lower surfaces of chocolate so as to prevent chocolate deforming caused by respective polishing and has a simple structure and popularizing and using values.

Owner:TIANJIN BINHAI NEW AREA AOTONG FOOD

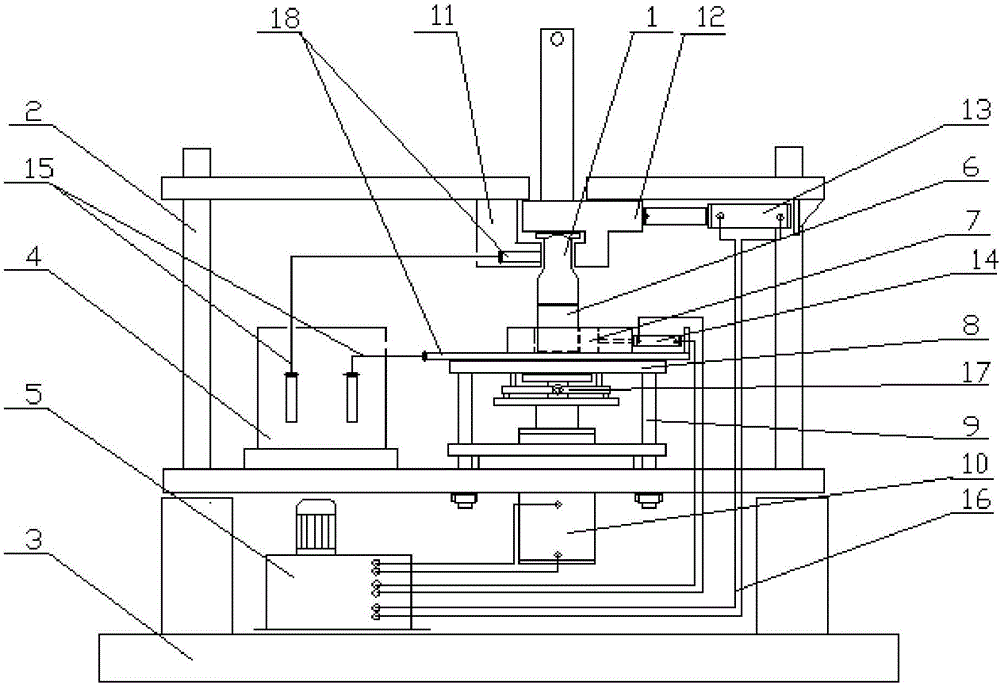

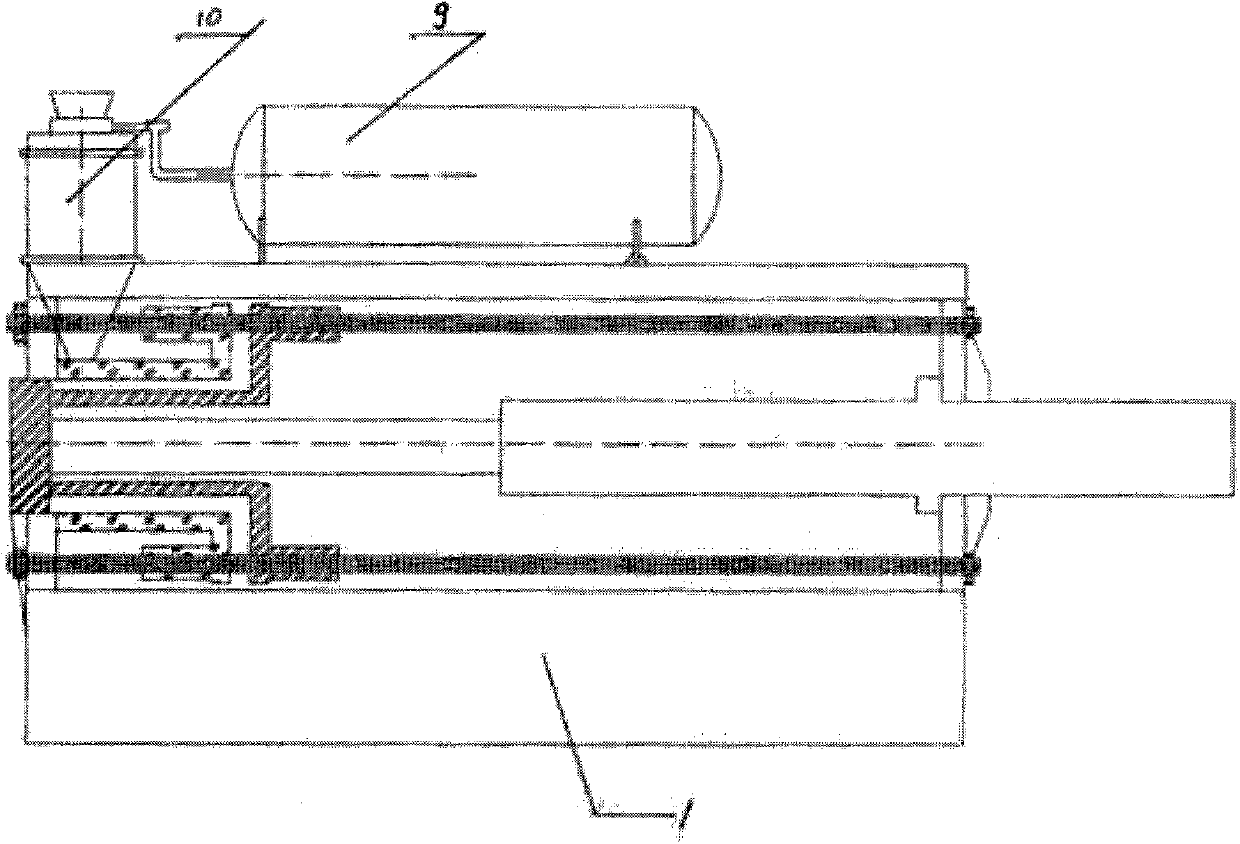

Vertical parting molding machine system

ActiveCN104057036ALow costReduce energy consumptionMoulding machinesProgrammable logic controllerMolding machine

The invention discloses a vertical parting molding machine system. The vertical parting molding machine system comprises a PLC (Programmable Logic Controller) system, a floor type machine seat and a sandbox assembly, wherein a forward pressure plate, a backward pressure plate and a backward pressure plate framework are arranged at the front part of the floor type machine seat; a transverse slide way is formed on the backward pressure plate framework; the backward pressure plate slides on the transverse slide way; a main oil cylinder framework is arranged at the rear end of the floor type machine seat; a main oil cylinder is fixed on the main oil cylinder framework; the backward pressure plate framework is connected with the main oil cylinder framework through four guide rods; the sandbox assembly is guided by the guide rods to slide forwards and backwards; a piston rod extending end of the main oil cylinder is perpendicularly and fixedly connected with the forward pressure plate; a guide plate of the forward pressure plate is guided by the four guide rods to slide forwards and backwards; a sand jetting barrel and a pressure air pocket are arranged above the sandbox assembly; a clutch device is arranged at each of the left end and the right end of the guide plate of the forward pressure plate; a pair of slide plates are correspondingly arranged at the two ends of the sandbox assembly. The vertical parting molding machine system achieves mechanization and automation of sand molding, is low in construction cost and energy consumption and small in occupied area, causes little pollution and has extensive popularizing and using values.

Owner:JIZE CHUANGJIE MACHINERY TECH CO LTD

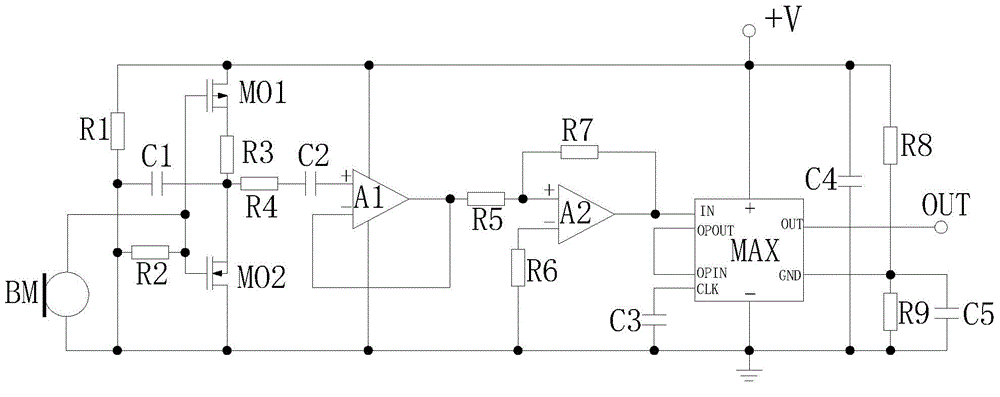

Voice signal acquisition circuit for ball mill load measurement

InactiveCN104682948AHelpful for analysisSimple structureLogic circuits coupling/interface using field-effect transistorsElectrical resistance and conductanceCapacitance

The invention discloses a voice signal acquisition circuit for ball mill load measurement. The voice signal acquisition circuit for ball mill load measurement comprises a first resistor, a second resistor, a third resistor, a fourth resistor, a fifth resistor, a sixth resistor, a seventh resistor, an eighth resistor, a ninth resistor, a voice sensor, a first capacitor, a second capacitor, a third capacitor, a fourth capacitor, a fifth capacitor, a first operational amplifier, a second operational amplifier, a first field-effect tube, a second field-effect tube and a capacitor filter. The voice signal acquisition circuit for ball mill load measurement has the advantages of stable working performance, high flexibility and strong adaptability, is suitable for various types of ball mills, can acquire voice signals generated when the ball mills are operated through the voice sensor, is beneficial to analysis of ball mill load parameters, meanwhile, is simple in structure and low in manufacturing cost, and has popularizing and applying values.

Owner:SICHUAN SINCO PHARMA

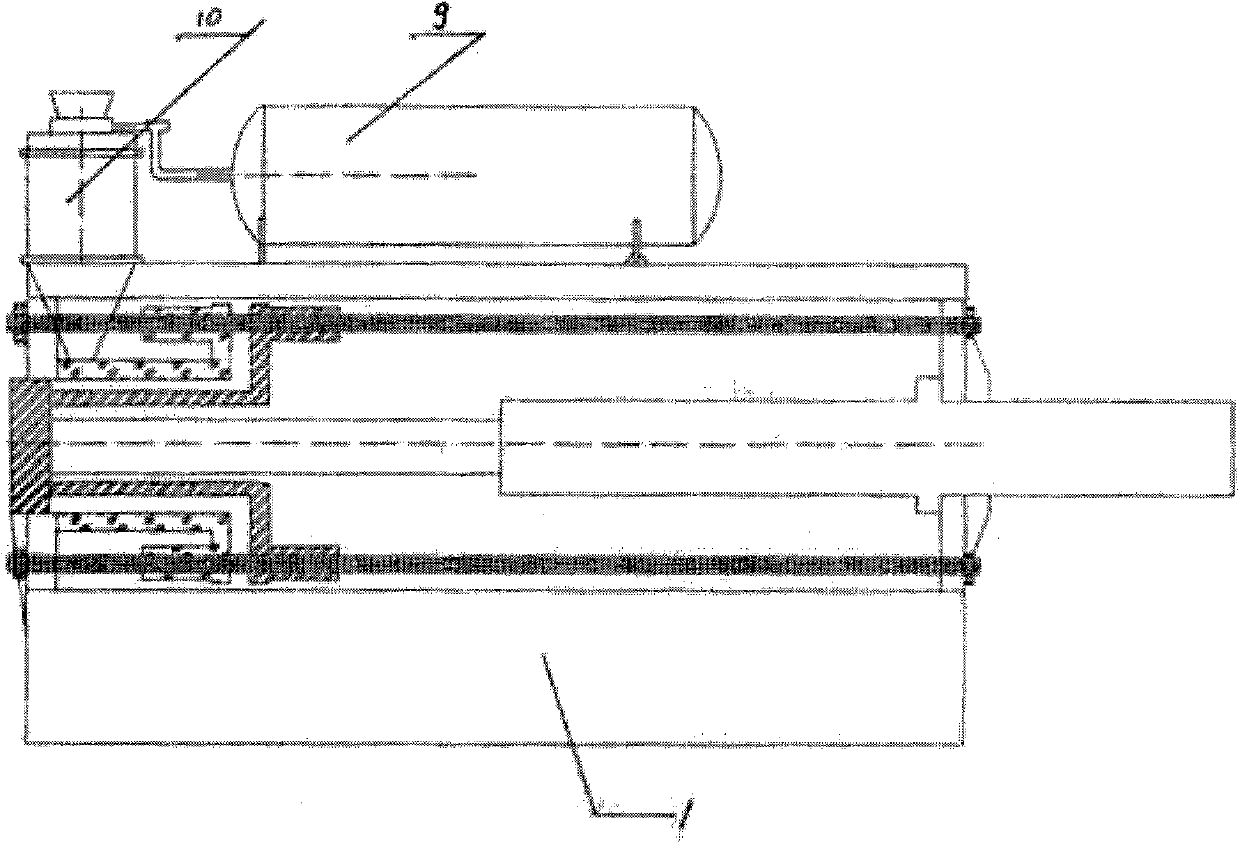

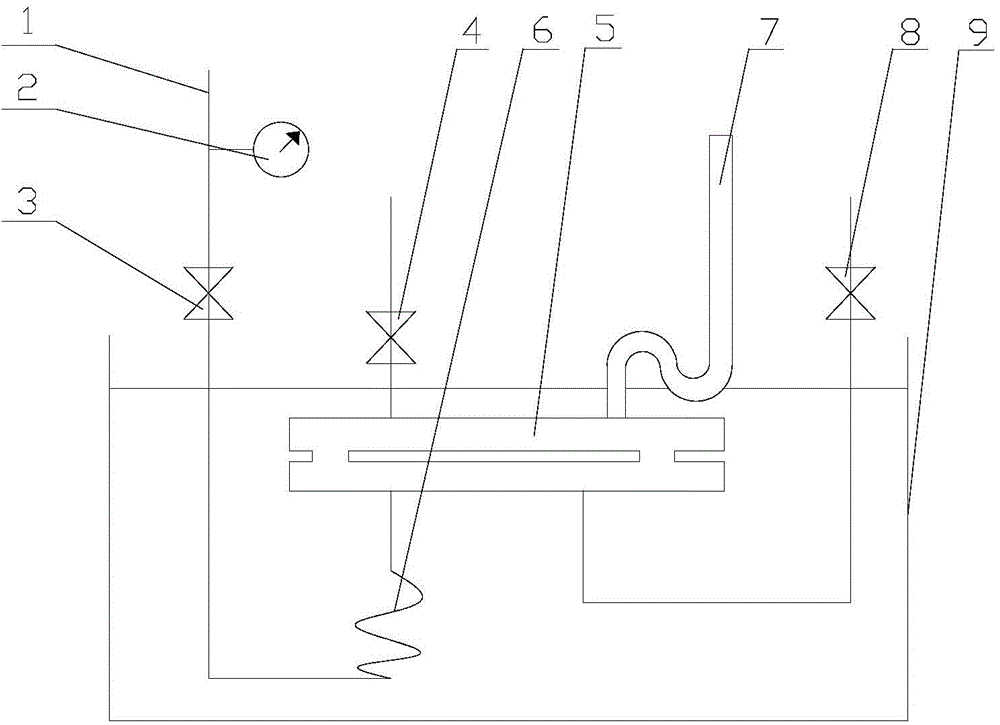

Packaging-material permeability testing apparatus

InactiveCN104458491ASimple structureReduce manufacturing costSurface/boundary effectPermeability/surface area analysisAlcoholPack material

A disclosed packaging-material permeability testing apparatus comprises a permeability determinator, a heating coil pipe and a U-shaped glass tube; the permeability determinator is arranged in a constant-temperature water pool; the permeability determinator also comprises a high-pressure gas chamber and a low-pressure gas chamber; a to-be tested packaging material is arranged between the high-pressure gas chamber and the low-pressure gas chamber; the high-pressure gas chamber is disposed below the low-pressure gas chamber, and the high-pressure gas chamber is connected with a first end of the heating coil pipe and a first gas output end; the second end of the heating pipe is connected with a gas inlet pipe; the low-pressure gas chamber is connected with the U-shaped glass tube and a second gas output end; and the U-shaped glass tube is inside provided with coloured ethyl alcohol. The packaging-material permeability testing apparatus is capable of finishing precise measure on permeability by employing the permeability determinator and the accessories, is simple in structure, relatively low in production cost and convenient to operate, and has popularization usage value.

Owner:天津市宏远钛铁有限公司

Formula and preparation process of indoor plant growth pottery clay

InactiveCN105993687ASlow precipitationGood effectCalcareous fertilisersSuperphosphatesPlant growthPotassium oxide

The invention discloses a formula and a preparation process of indoor plant growth pottery clay. The pottery clay is composed of leaf mould, mountain clay, field soil, grass ash, slaked lime, river sand, diammonium phosphate, conifer leaves, decomposed chicken manure, nitric nitrogen, water-soluble phosphoric anhydride, water-soluble potassium oxide, water-soluble magnesium oxide, water-soluble boron, sawdust, urea, calcium superphosphate, potassium sulfate and rooting powder. Compared with prior arts, the formula and the preparation process have the advantages that the planting material is prepared from pottery clay. The pottery clay is impregnated with nutrients, and the nutrients can be separated out slowly, such that a long-lasting effect can be kept. The formula and the preparation process have popularization and application values.

Owner:ZUZI TECH SHENZHEN CO LTD

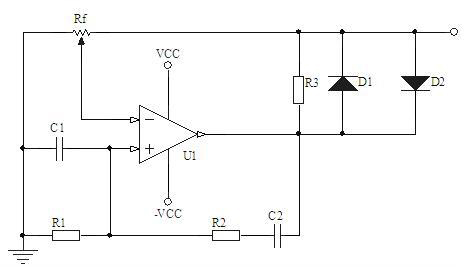

Sine wave generation circuit

InactiveCN102497165ASimple structureImprove performanceOscillations generatorsAudio power amplifierOperational amplifier

The invention discloses a sine wave generation circuit. The sine wave generation circuit comprises an operational amplifier, wherein an output end of the operational amplifier is grounded through a second resistor and a first resistor connected in series, a connection end between the second resistor and the first resistor is connected with an in-phase input end of the operational amplifier, an anti-phase input end of the operational amplifier is connected with an adjustable end pin of an adjustable resistor, one of two fixed end pins of the adjustable resistor is grounded, and the other one is connected to the output end of the operational amplifier through a third resistor, and the connection end between the adjustable resistor and the third resistor is led out to be used as the output end of the sine wave generation circuit. The sine wave generation circuit is simple in structure, and steady and reliable in performance, and has popularization and use value.

Owner:SUZHOU HEXINMEI ELECTRONICS SCI & TECH CO LTD

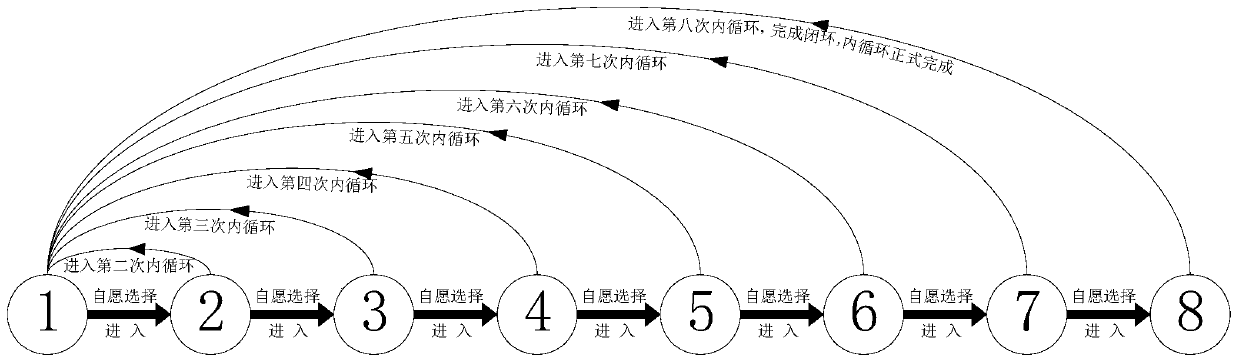

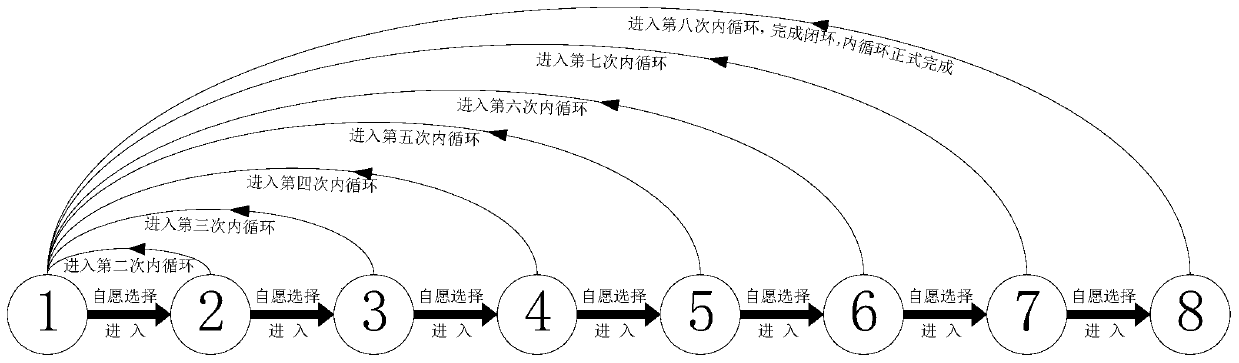

Online mutual promotion sales method

InactiveCN110009422ARealize rational utilizationIncrease salesMarketingData miningOperations research

The invention belongs to the technical field of product marketing, and aims to provide an online mutual promotion sales method. The method comprises the following steps: S1, establishing a main account database in an account database according to registration information of a main account, then grading the main account as a primary authority level in the main account database, and establishing a current consumption product point for the main account in the main account database; s2, if the current consumption product point accumulates to reach a first product point level, re-grading the main account as a middle-level permission level, and then establishing a unique identification code for the main account in a main account database; and S3, judging whether the main account database is re-graded into a high-level authority level according to the marked frequency of the identification code of the main account and / or the current consumption product point, and if the main account databaseis re-graded into the high-level authority level, establishing a first bonus product point for the main account in the main account database. New client resources can be introduced according to existing client resources.

Owner:四川心源互促电子商务有限公司

A kind of high-efficiency planting method of Yuanhu

ActiveCN107646335BGrow fastEarly emergencePlant protectionVegetative propogationSeedlingUnderground stem

The invention discloses a high-efficiency planting method of Rhizoma chinensis, which grows faster and has a shorter growth cycle. It takes only about 210 days from sowing to harvesting, and at least 100-120 days from high-yield sowing to rhizome growth before emergence. This is followed by tuber formation. Compared with the prior art, adopting the present invention to plant Rhizoma Rhizome, the growth of Rhizoma Rhizome is fast, the emergence is early and neat, the period from emergence to harvest is extended by 7-10 days, the growth period is prolonged, the yield and quality of Rhizoma Rhizome are improved, and it has the advantages of Promote the value of use.

Owner:HANZHONG CITY AGRI TECH PROMOTION CENT

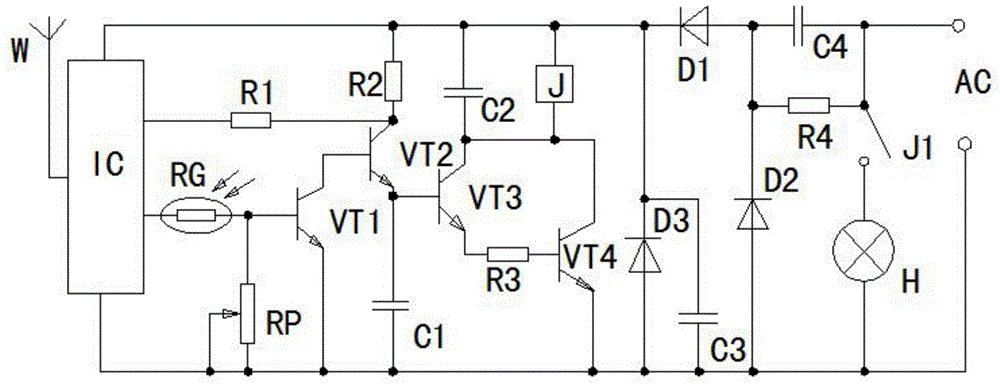

Automatic floodlight circuit for toilet

InactiveCN104661356AEasy to useHas the value of promotion and useElectric light circuit arrangementCapacitanceElectrical resistance and conductance

The invention discloses an automatic floodlight circuit for a toilet. The automatic floodlight circuit comprises first to fourth resistors, first to fourth capacitors, first to fourth triodes, first to third diodes, a body proximity switch, a photoresistor, a potentiometer, a bulb, a relay and an antenna. In comparison with the prior art, the automatic floodlight circuit for toilet adopts the body proximity switch as a core element and the peripheral elements to form a microwave human induction switch, when a person is induced, the microwave human induction switch is started and is not affected by various factors, such as ray, temperature and environment, and the automatic floodlight circuit is convenient to use and has popularization and application value.

Owner:CHENGDU BOYNN TECH

Short-circuit protection circuit

InactiveCN102386607ASimple structureImprove performanceArrangements responsive to excess currentShort circuit protectionLight-emitting diode

The invention discloses a short-circuit protection circuit. The short-circuit protection circuit comprises a first voltage input end which is grounded with a second divider resistor through a first divider resistor, the connecting end of the first divider resistor connecting with the second divider resistor is connected to the base electrode of a triode through a third resistor, the collecting electrode of the triode is connected to the input end of a second voltage through a first resistor, the emitting electrode of the triode is grounded, the triode is led out from the connecting end of the first resistor to serve as a voltage output end, and an LED is arranged between the collecting electrode and the emitting electrode of the triode in a bridging manner. The short-circuit protection circuit uses fewer circuit components, and has a simple structure, stable properties, and popularization and use values.

Owner:SUZHOU HEXINMEI ELECTRONICS SCI & TECH CO LTD

High stable power supply control circuit of electronic communication equipment

InactiveCN104678784AGuaranteed uptimeSimple structureProgramme control in sequence/logic controllersCapacitanceTransformer

The invention discloses a high stable power supply control circuit of electronic communication equipment, which comprises a transformer, a rectifier, first to fifth capacitors, a first diode, a second diode, first to fourth resistors, a field effect tube, a triode, a thyristor and a potentiometer; when output voltage is heightened, the potential of a control terminal of the thyristor is increased, the cathode voltage of the thyristor is reduced, and after regulation of the field effect tube, the potential of an emitter of the triode is increased, so the output voltage is stable. When output current is larger than a set value, the triode is stopped, so the output current is limited within the set value to achieve a current stabilizing aim. Compared with prior art, the high stable power supply control circuit has the advantages that the circuit is simple in structure, adopts less electronic elements, and is low in cost and favorable for popularization, particularly, the high stable power supply control circuit is stable in output voltage and guarantees the stable operation of the communication equipment, the communication quality is improved and the circuit has promotion and use values.

Owner:CHENGDU BIZ UNITED INFORMATION TECH

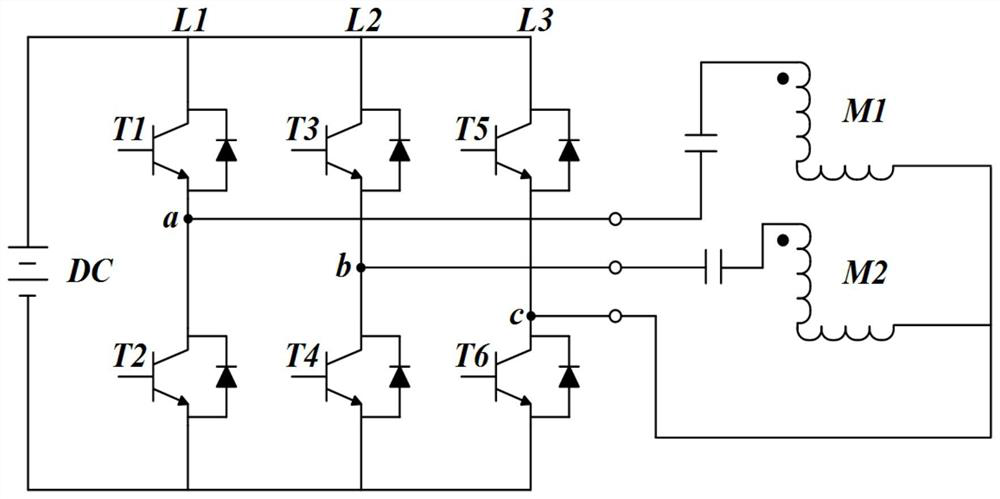

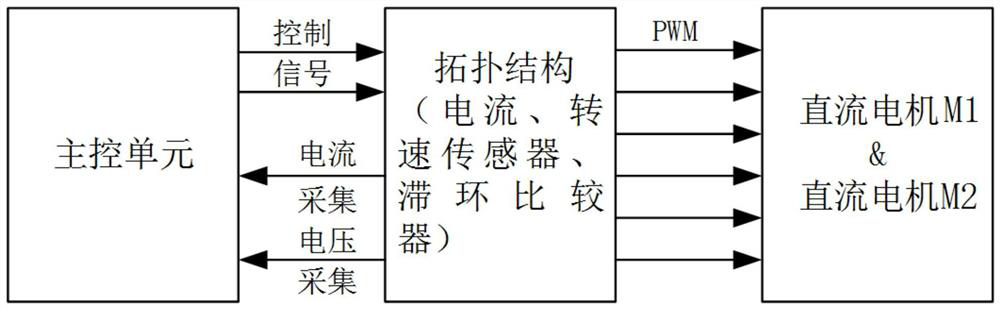

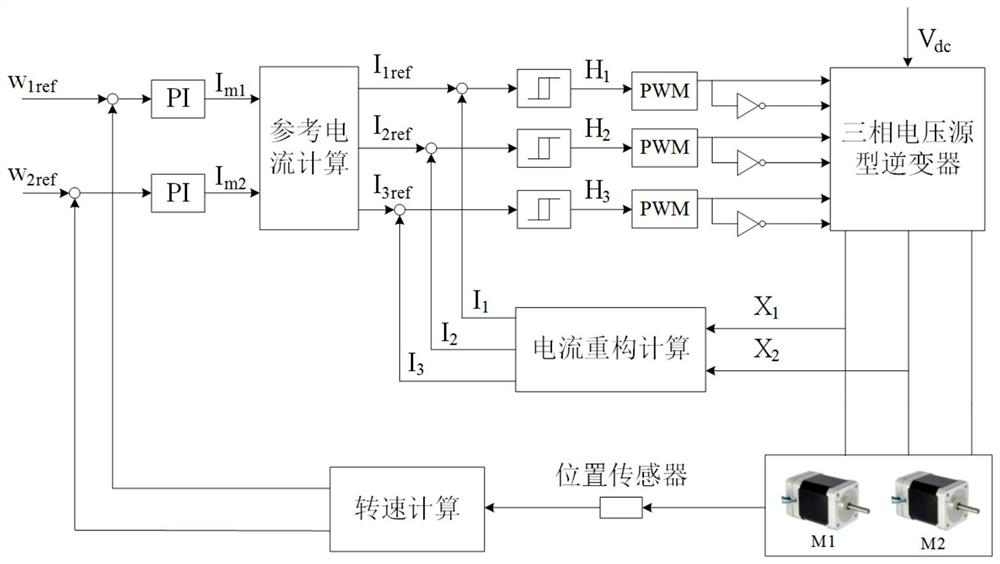

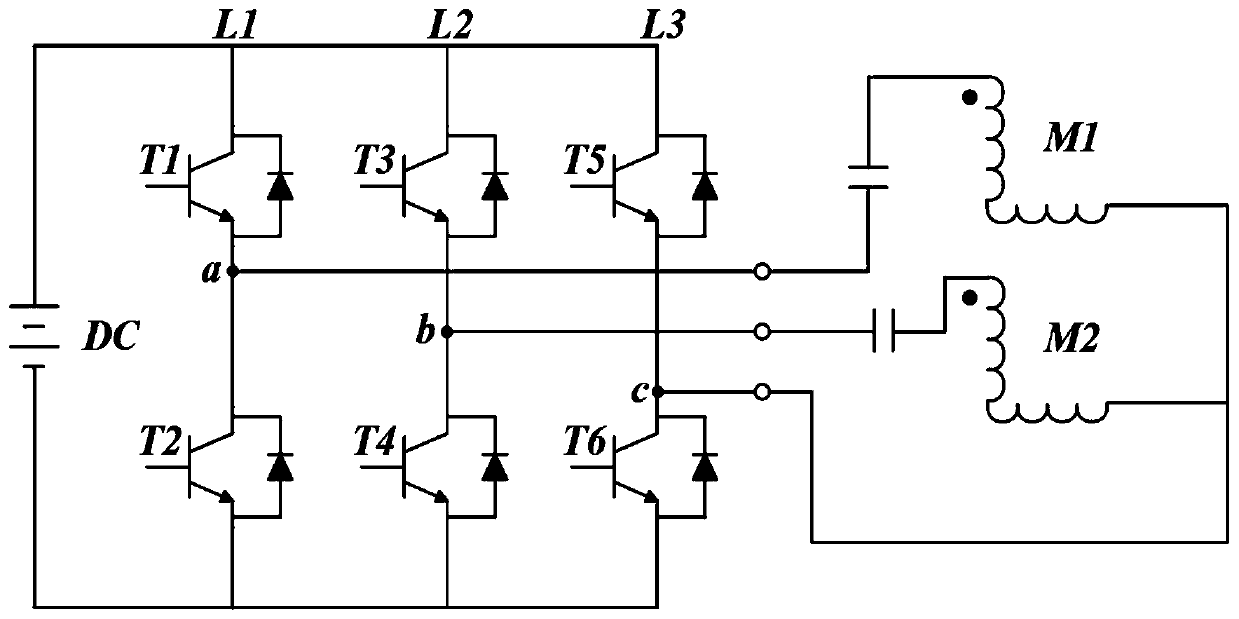

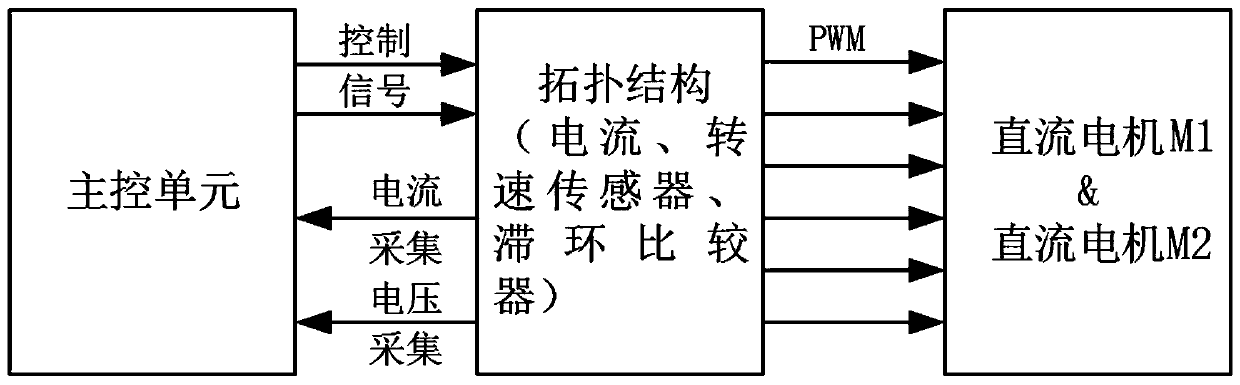

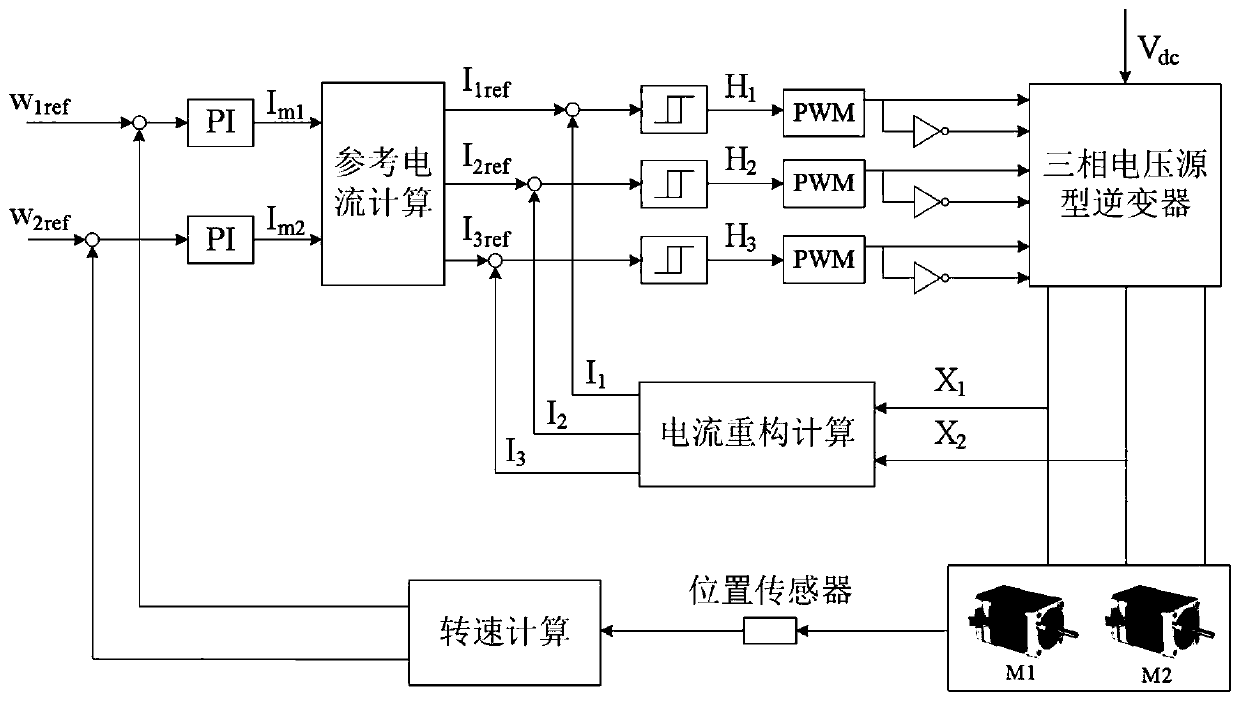

A dual DC motor parallel system and current hysteresis control method

ActiveCN111464075BImprove responsivenessQuick responseField or armature current controlMultiple dc dynamo-electric motors controlDC - Direct currentReference current

The invention discloses a dual DC motor parallel system and a current hysteresis loop control method, which collects the rotational speed signal and the current signal of the dual DC motor; and obtains the speed error by passing the system set reference speed and the actual rotational speed signal of the DC motor through a speed adjustment module , the speed error is obtained through the PI controller to obtain the reference current; the current synthesis calculation is performed on the reference current to obtain three sets of combined current; the current reconstruction calculation is performed on the collected current signal to obtain three sets of reconstructed current signals; through the hysteresis comparator, The synthesized current signal is compared with the reconstructed current signal to generate a PWM pulse signal to control the working state of the switching device of the inverter circuit and realize the drive of the dual DC motors. The invention improves the current response speed, realizes the rapid supplement to the harmonic current, reduces the tracking error of the system, and has strong stability.

Owner:CHANGAN UNIV

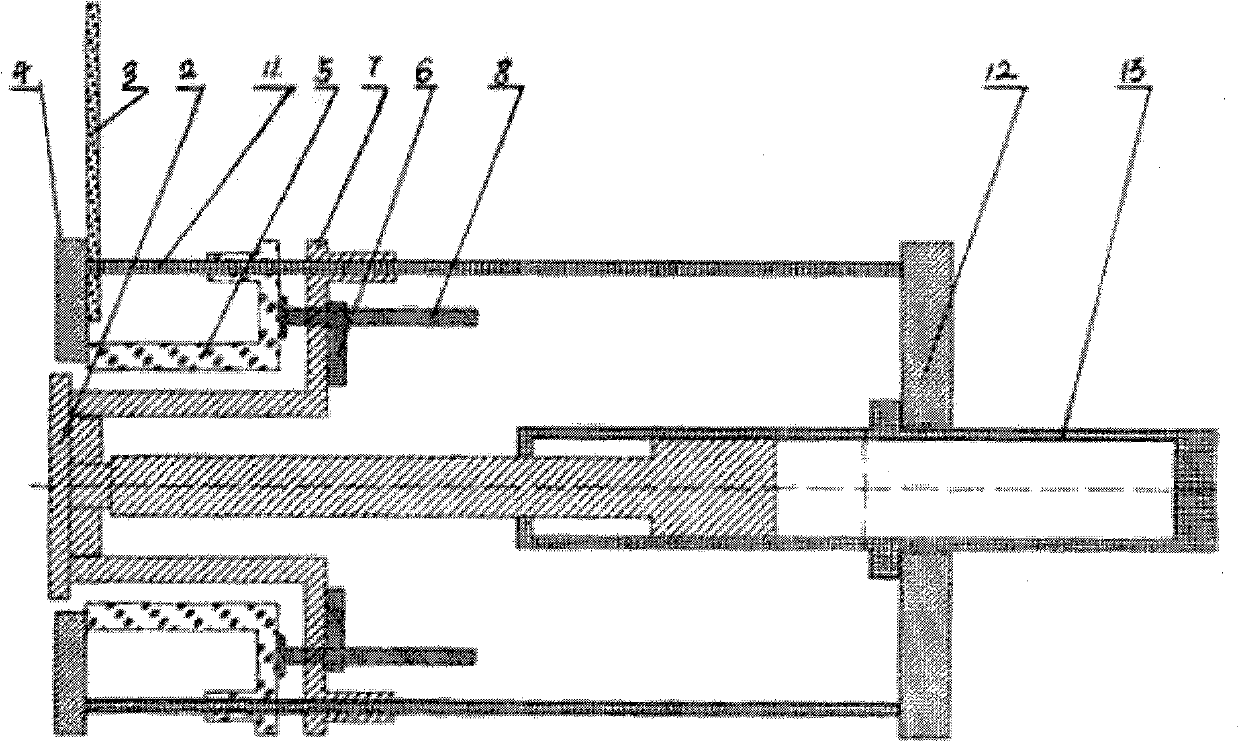

A vertical parting molding machine system

ActiveCN104057036BLow costReduce energy consumptionMoulding machinesProgrammable logic controllerMolding machine

The invention discloses a vertical parting molding machine system. The vertical parting molding machine system comprises a PLC (Programmable Logic Controller) system, a floor type machine seat and a sandbox assembly, wherein a forward pressure plate, a backward pressure plate and a backward pressure plate framework are arranged at the front part of the floor type machine seat; a transverse slide way is formed on the backward pressure plate framework; the backward pressure plate slides on the transverse slide way; a main oil cylinder framework is arranged at the rear end of the floor type machine seat; a main oil cylinder is fixed on the main oil cylinder framework; the backward pressure plate framework is connected with the main oil cylinder framework through four guide rods; the sandbox assembly is guided by the guide rods to slide forwards and backwards; a piston rod extending end of the main oil cylinder is perpendicularly and fixedly connected with the forward pressure plate; a guide plate of the forward pressure plate is guided by the four guide rods to slide forwards and backwards; a sand jetting barrel and a pressure air pocket are arranged above the sandbox assembly; a clutch device is arranged at each of the left end and the right end of the guide plate of the forward pressure plate; a pair of slide plates are correspondingly arranged at the two ends of the sandbox assembly. The vertical parting molding machine system achieves mechanization and automation of sand molding, is low in construction cost and energy consumption and small in occupied area, causes little pollution and has extensive popularizing and using values.

Owner:JIZE CHUANGJIE MACHINERY TECH CO LTD

A kind of electric vehicle charging management control method

ActiveCN108773281BWill not cause power lossHigh degree of intelligenceCharging stationsElectric vehicle charging technologyLow voltageElectric vehicle

The invention relates to the field of electric control of electric automobiles, and aims to provide a charging management control method for an electric automobile capable of effectively avoiding lackof electricity of a low voltage storage battery. The technical scheme is that the charging management control method for the electric automobile includes the following steps: a vehicle controller automatically enters a charging mode; a BMS judges a type of a charging pile; when the charging pile is a direct current charging pile, a low voltage supplementary electricity voltage of the direct current charging pile is measured; when the low voltage supplementary electricity voltage of the direct current charging pile is identical to a rated voltage of the low voltage storage battery of the electric mobile, the low voltage battery is directly charged by a low voltage supplementary electricity interface of the direct current charging pile; and when the low voltage supplementary electricity voltage of the direct current charging pile is different from the rated voltage of the low voltage storage battery of the electric mobile, a direct current converter of the electric automobile is startedand converts high-voltage power of a high-voltage power storage battery into low-voltage power corresponding to the low-voltage storage battery, and electricity is supplemented to the low-voltage storage battery. The charging management control method enables the lack of electricity of the low voltage storage battery to be avoided.

Owner:CHENGDU RAJA NEW ENERGY AUTOMOTIVE TECH CO LTD

Double-DC-motor parallel system and current hysteresis control method

ActiveCN111464075AImprove responsivenessQuick responseField or armature current controlMultiple dc dynamo-electric motors controlReference currentHemt circuits

The invention discloses a double-DC-motor parallel system and a current hysteresis control method. The method includes steps that rotating speed signals and current signals of double direct current motors are collected; the system set reference speed and the actual rotating speed signal of the direct current motor are made to pass through a speed adjusting module to obtain a speed error, and the speed error is made to pass through a PI controller to obtain a reference current; current synthesis calculation of the reference current is performed to obtain three groups of combined currents; current reconstruction calculation of the collected current signals is performed to obtain three groups of reconstructed current signals; the synthesized current signal is compared with the reconstructed current signal through a hysteresis comparator to generate a PWM pulse signal, and a working state of an inverter circuit switching device is controlled, so driving of the double DC motors is realized.The method is advantaged in that the current response speed is improved, the harmonic current is quickly supplemented, a tracking error of the system is reduced, and stability is very high.

Owner:CHANGAN UNIV

A forward series control system and method for multiple DC motors

ActiveCN108683367BReduce in quantityClear structureField or armature current controlDC motor rotation controlPulse controlControl system

Owner:徐州博柯斯健康科技有限公司

Method for extracting genome DNA from phyllachora ascocarp

The invention discloses a method for extracting genome DNA from phyllachora ascocarp. Compared with the prior art, the method has the advantage that the phyllachora ascocarp is utilized as a material for directly extracting DNA. Before the extraction of DNA, a lysate buffer solution is utilized for processing twice, excessive colloids and polysaccharides are removed by virtue of a principle that DNA is low in solubility at a low temperature, finally an extracting solution is added to split cell membranes to extract DNA, and phenol-chloroform-isoamylol is added in the extraction process to remove redundant proteins through extraction. The method is applicable to fungi materials with high contents of colloids, polysaccharides and proteins, the yield and the quality of the extracted DNA are not obviously influenced by the existence and the content of impurities, and the guarantee is provided for the subsequent molecular research of phyllachora; and the method has popularization and use values.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

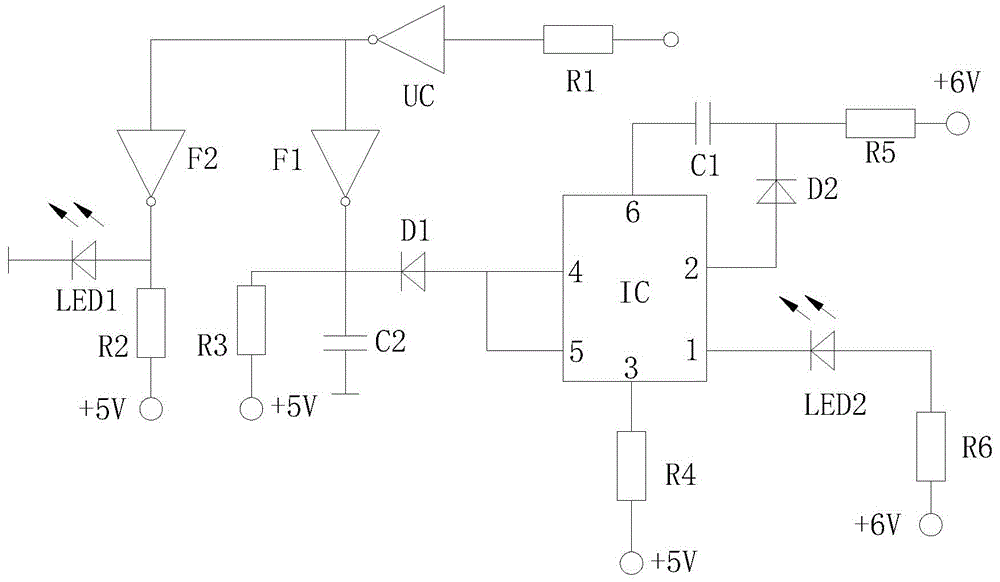

Sensor circuit of alarm

InactiveCN104637264ASimple structureHigh sensitivityVisible signalling systemsAlarmsEngineeringLight-emitting diode

The invention discloses a sensor circuit of an alarm. The sensor circuit of the alarm comprises a first resistor, a second resistor, a third resistor, a fourth resistor, a fifth resistor, a sixth resistor, a bus register, a first phase inverter, a second phase inverter, a first diode, a second diode, a first capacitor, a second capacitor, a first light emitting diode, a second light emitting diode and a power management chip, wherein the model of the power management chip is 9602; and a first end of the first resistor is a signal inputting end. The sensor circuit of the alarm is a CMOS (complementary metal-oxide-semiconductor transistor) alarming circuit consisting of the bus register, the phase inverters and the power management chip. The sensor circuit is mainly used for the alarm; when low level is inputted, the first light emitting diode is not turned on; when high level is inputted, the first light emitting diode is turned on; and when high level inputting is changed into low level inputting or low level inputting is changed into high level inputting, the second light emitting diode twinkles once. The sensor circuit of the alarm is simple in structure and high in sensitivity, and has popularization and using value.

Owner:CHENGDU WANWEI TUXIN INFORMATION TECH

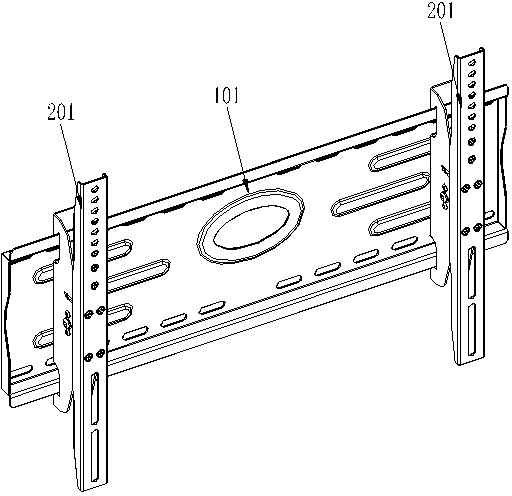

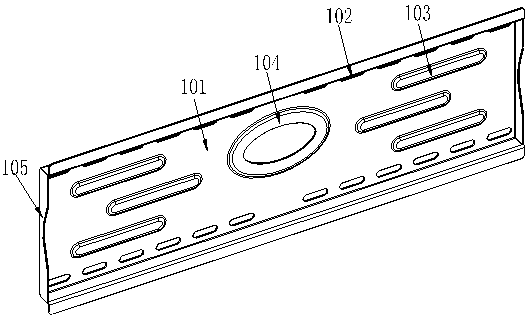

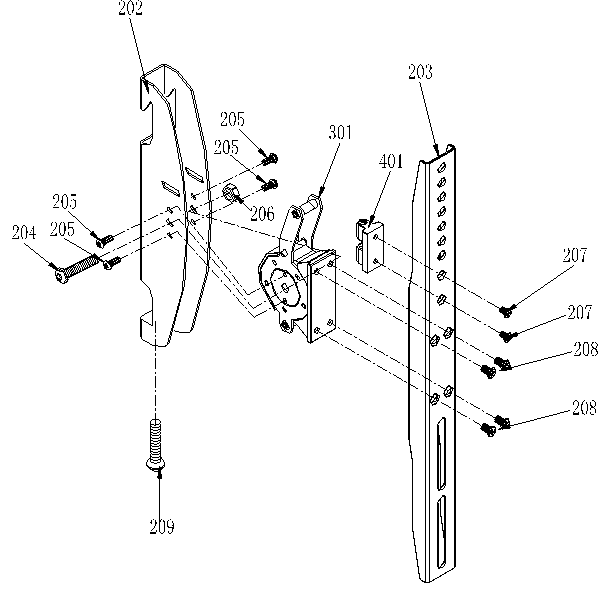

Television support adjusted through ratchet wheel

InactiveCN103727370AChange tilt angleSimple structureStands/trestlesMechanical engineeringCable television

The invention discloses a television support adjusted through a ratchet wheel. The television support adjusted through the ratchet wheel comprises a wall connecting board and two hanging rods. Each hanging rod comprises a hanger, a long strip rod and a ratchet wheel base. The two ends of each hanger are provided with a hanging opening. Each hanger is hung on the wall connecting board through the hanging openings. Each ratchet wheel base is arranged in the corresponding hanger. A fixed base of each ratchet wheel base is fixedly connected with the corresponding hanger. A rotary base of each ratchet wheel base is fixedly connected with the corresponding long strip rod. According to the television support adjusted through the ratchet wheel, through adjustment of the ratchet wheel bases, the inclination angle of a television is changed, the structure is simple, cost is low, operation is convenient, and the television support has the popularization and use value.

Owner:裴旭波

A method for extracting genome dna from the ascomycetes of the mole fungus

The invention discloses a method for extracting genome DNA from phyllachora ascocarp. Compared with the prior art, the method has the advantage that the phyllachora ascocarp is utilized as a material for directly extracting DNA. Before the extraction of DNA, a lysate buffer solution is utilized for processing twice, excessive colloids and polysaccharides are removed by virtue of a principle that DNA is low in solubility at a low temperature, finally an extracting solution is added to split cell membranes to extract DNA, and phenol-chloroform-isoamylol is added in the extraction process to remove redundant proteins through extraction. The method is applicable to fungi materials with high contents of colloids, polysaccharides and proteins, the yield and the quality of the extracted DNA are not obviously influenced by the existence and the content of impurities, and the guarantee is provided for the subsequent molecular research of phyllachora; and the method has popularization and use values.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

A forward series control system and method for three DC motors

ActiveCN108809157BReduce in quantityClear structureElectric motor speed/torque regulationPulse controlControl system

The invention discloses a control system and method with three direct-current motors in forward-direction serial connection. The system is characterized in that eight IGBT modules form four bridge arms in a two-two serial connection manner, the four bridge arms are parallelly connected to the positive electrode and the negative electrode of a direct-current power supply, the three direct-current motors in forward-direction serial connection are serially connected with the four bridge arms, the three direct-current motors are connected with a reference voltage synthesizer sequentially through aspeed sensor, a current sensor, a speed adjusting module and a secondary PI controller, the reference voltage synthesizer is connected with a four-phase inverter through a PWM pulse generating unit,the four-phase inverter is connected with the reference voltage synthesizer through a current adjusting module and a primary PI controller, the four-phase inverter is connected to the PWM pulse generating unit through the reference voltage synthesizer, and pulse control signals generated by the PWM pulse generating unit controls the on and off of the eight IGBT modules to drive the three direct-current motors to operate. The control system is few in used circuit components, simple in structure, stable and reliable in performance and worthy of popularization and application.

Owner:TIANJIN SAIXIANG M&E ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com