Double-DC-motor parallel system and current hysteresis control method

A dual DC motor, DC motor technology, applied in the direction of DC motor speed/torque control, excitation or armature current control, control of multiple DC motors, etc., can solve the complex debugging process, many adjustable parameters of PI controller, system fluctuation and other problems, to achieve the effect of improving current response, enhancing fast response capability, and reducing component cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

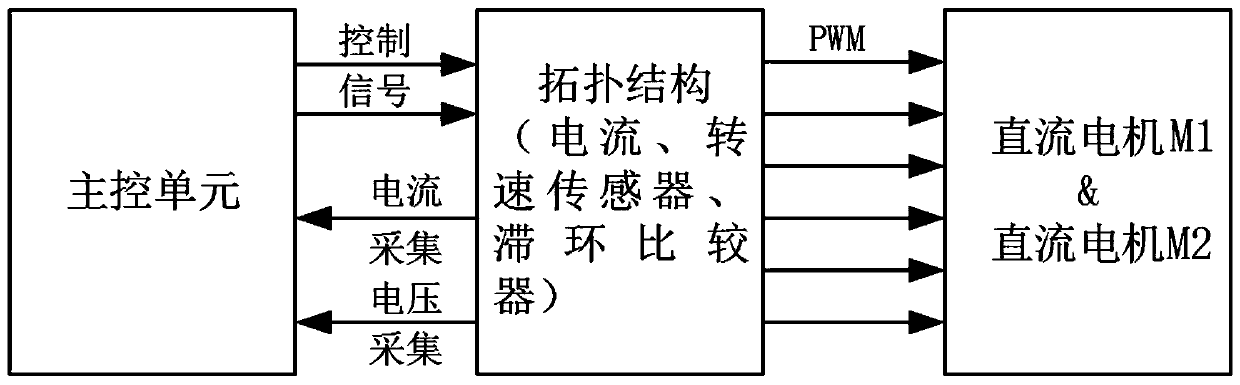

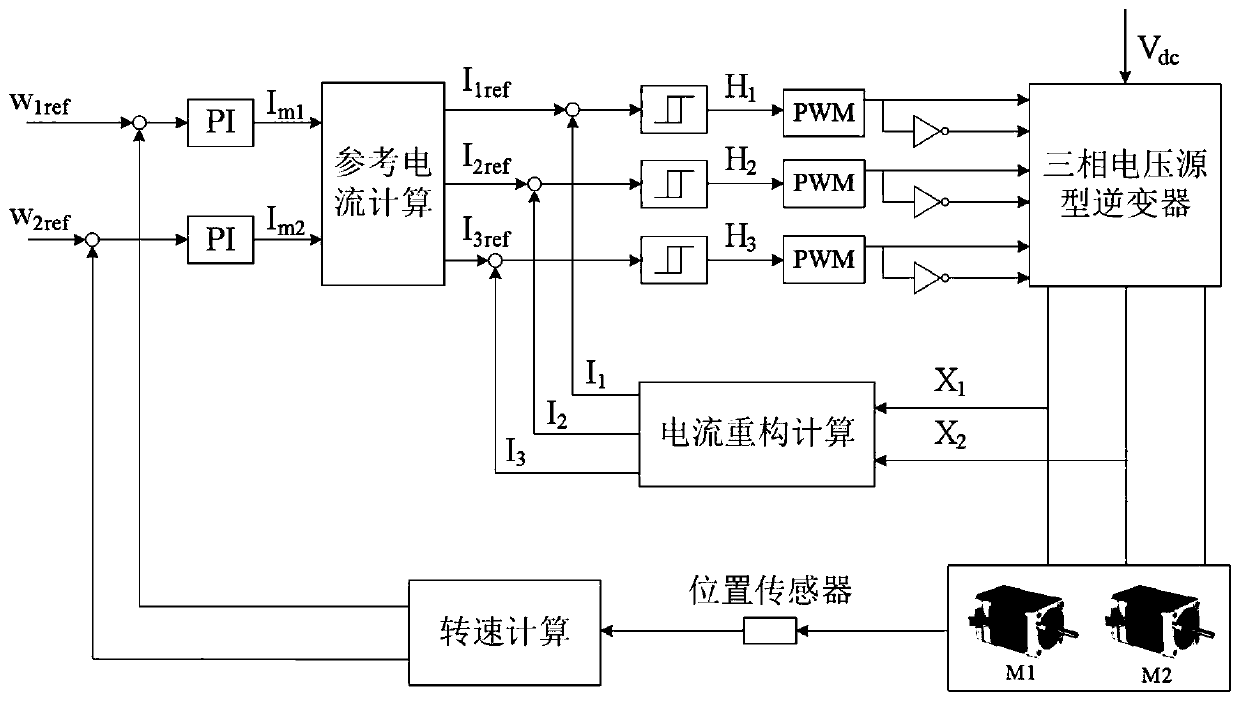

[0058] The present invention provides a current hysteresis control method and system based on dual DC motors. The actual speed of the motor and the reference speed are PI adjusted to obtain the value of the reference current, and then the reference current is synthesized, and after reconstruction calculation The actual current of the motor is adjusted by PI again, and the obtained current is controlled by hysteresis, and the three-phase inverter circuit is driven by PWM pulse regulation, so that the current hysteresis control of the double DC motor parallel system is realized.

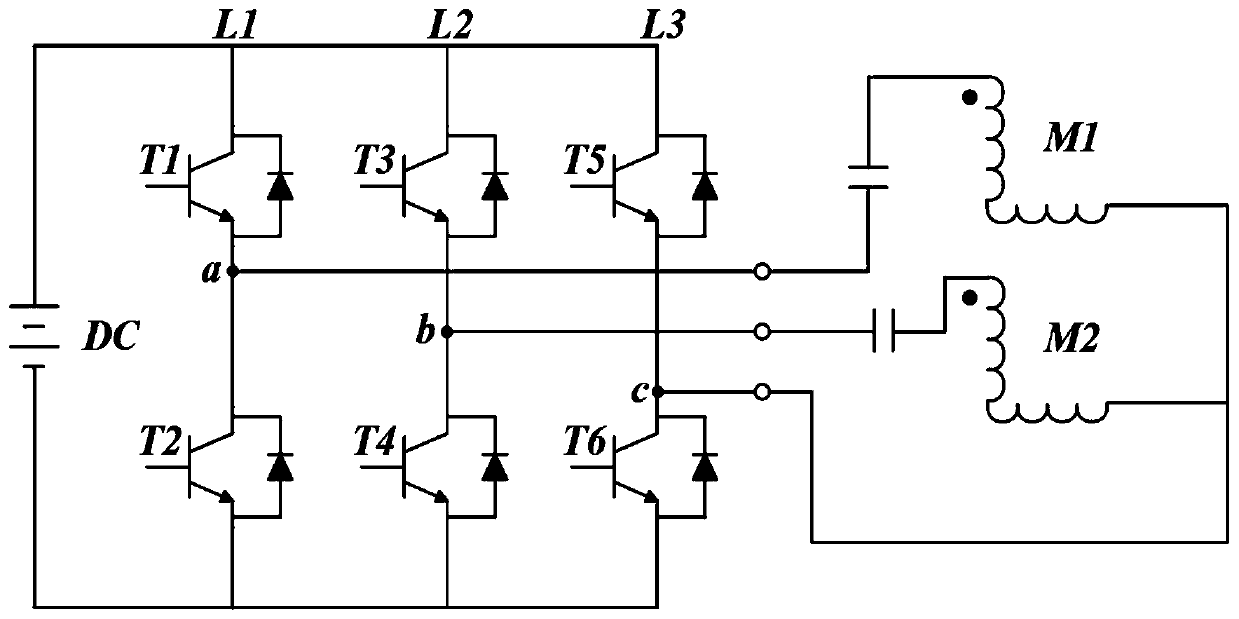

[0059] see figure 1 with figure 2 , a dual DC motor parallel system of the present invention adopts a dual DC motor three-arm inverter structure, including:

[0060] The controller, the inverter bridge arm L1, the inverter bridge arm L2 and the inverter bridge arm L3; the three-phase inverters are connected in parallel and connected to a common DC power supply.

[0061] DC motor M1:

[0062] The po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com