Voice signal acquisition circuit for ball mill load measurement

A technology of sound signal and load detection, which is applied in the direction of logic circuit coupling/interface and logic circuit connection/interface arrangement using field effect transistors, which can solve the problem of inability to achieve optimal control of ball mills, affect the application range, and fail to detect the load status of ball mills and other problems, to achieve the effect of stable performance, high sensitivity and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

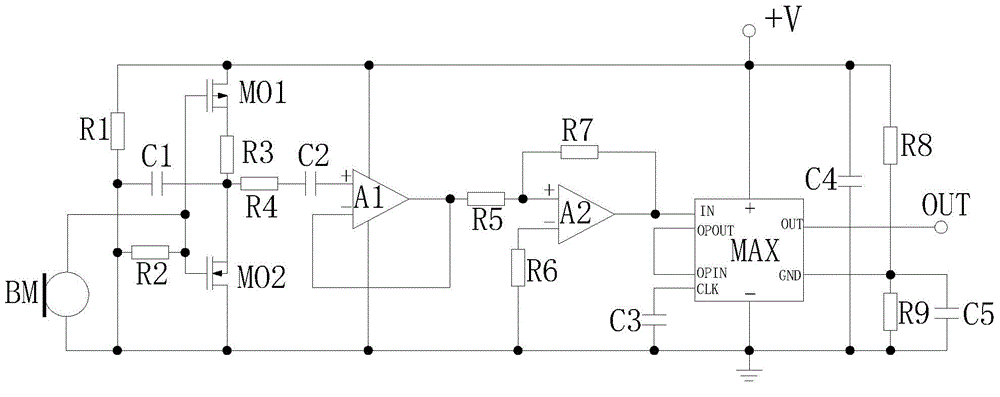

[0010] The present invention will be further described below in conjunction with accompanying drawing:

[0011] Such as figure 1 Shown: the present invention includes a first resistor R1, a second resistor R2, a third resistor R3, a fourth resistor R4, a fifth resistor R5, a sixth resistor R6, a seventh resistor R7, an eighth resistor R8, and a ninth resistor R9 , sound sensor BM, first capacitor C1, second capacitor C2, third capacitor C3, fourth capacitor C5, fifth capacitor C5, first operational amplifier A1, second operational amplifier A2, first field effect transistor MO1, second Two field effect transistors MO2 and capacitor filter MAX, the first end of the first resistor R1 is simultaneously connected with the drain of the first field effect transistor MO1, the positive pole voltage input terminal of the first operational amplifier A1, and the positive pole of the capacitor filter MAX The voltage input terminal, the first terminal of the fourth capacitor C4, the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com