Vertical parting molding machine system

A vertical parting and molding machine technology, applied in molding machines, manufacturing tools, casting and molding equipment, etc. low pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing:

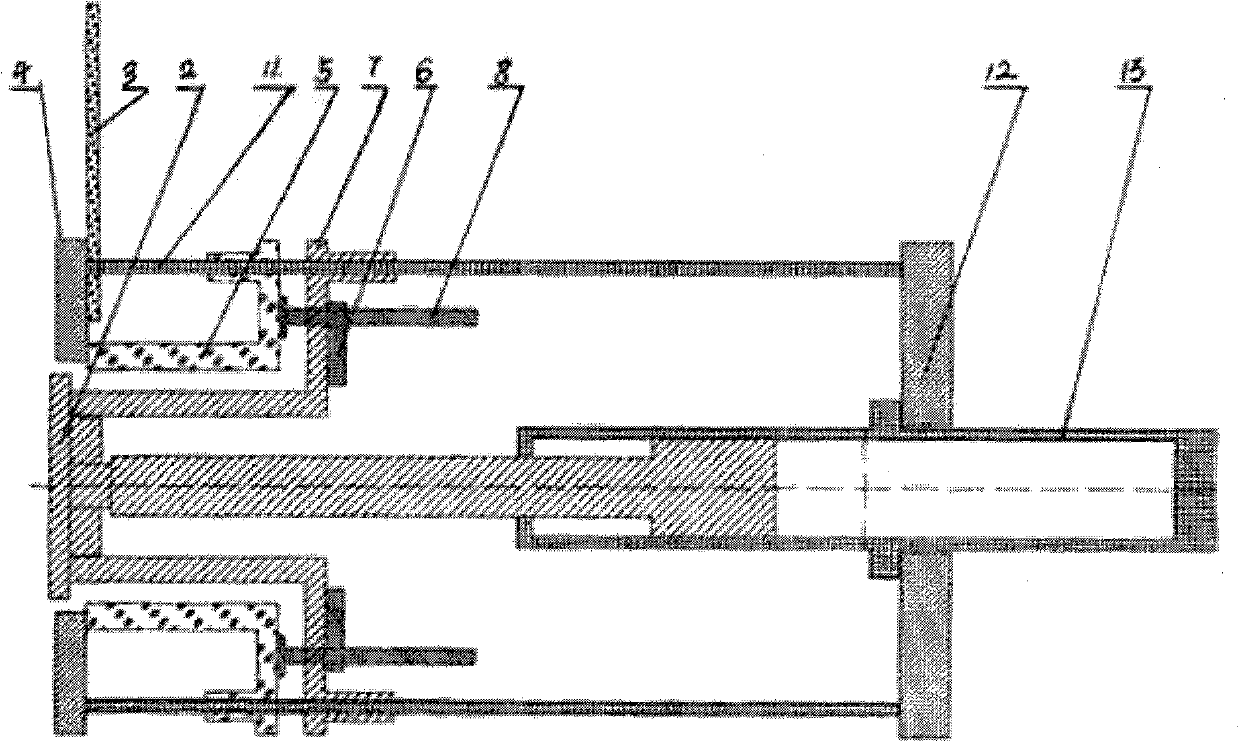

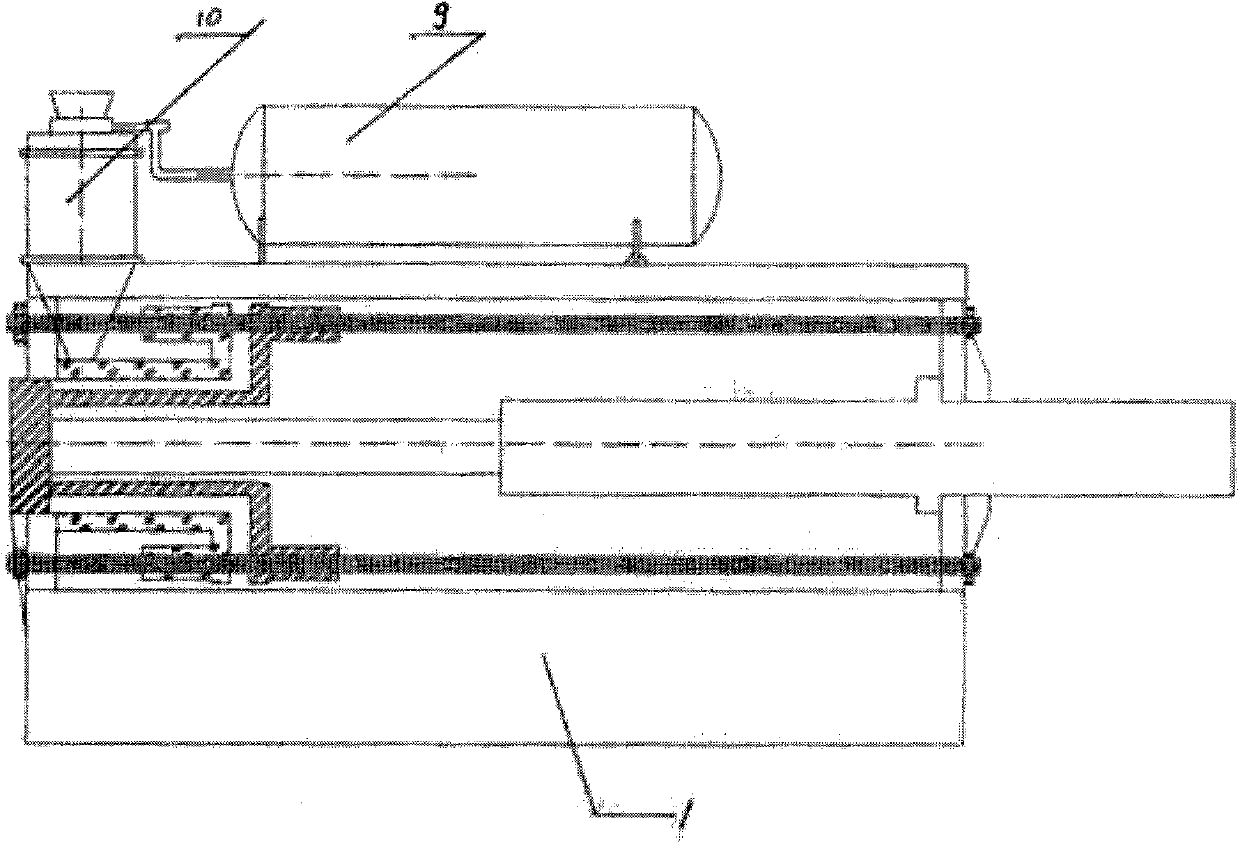

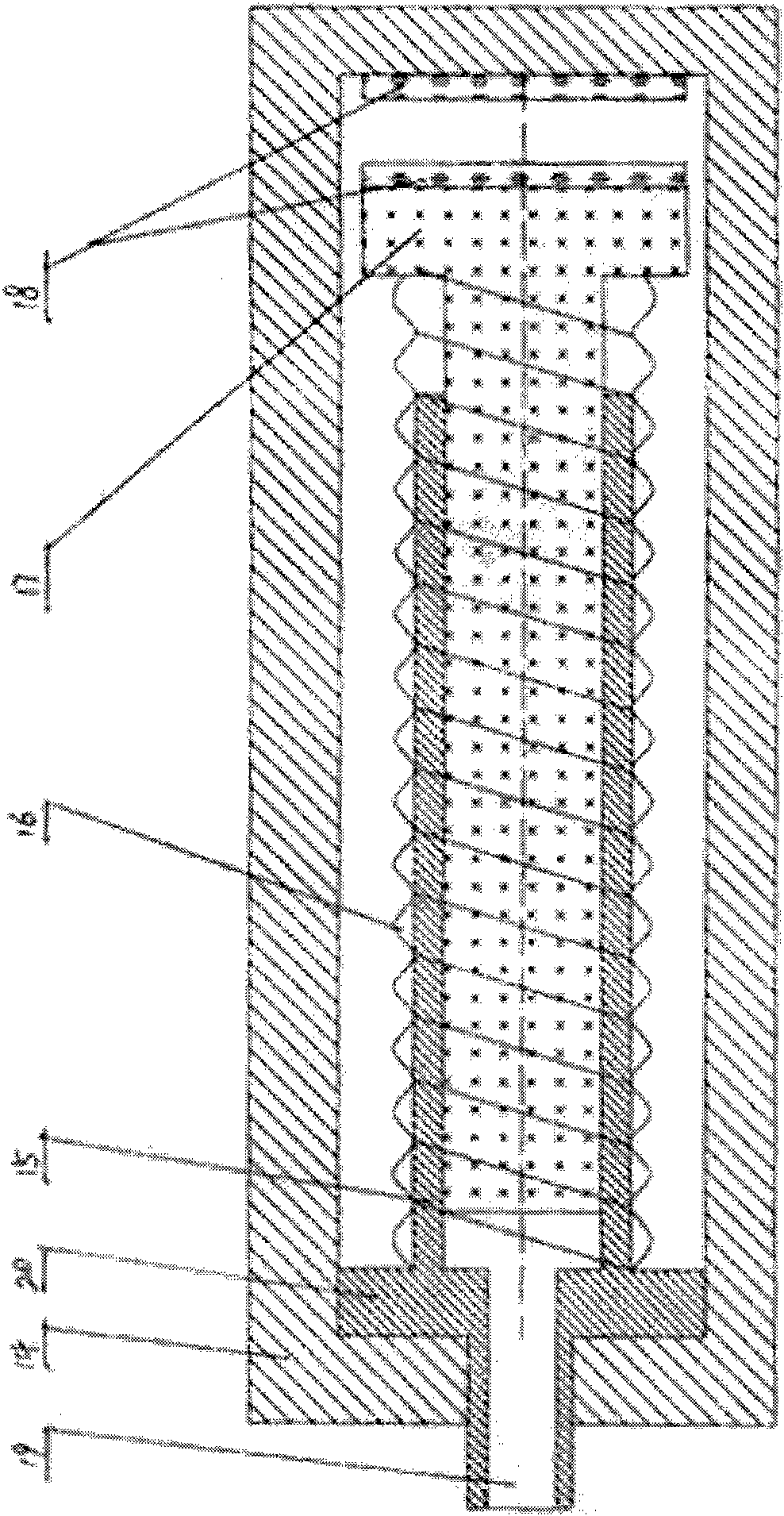

[0017] like figure 1 and figure 2 As shown, a vertical parting molding machine system of the present invention includes a PLC control system, a floor-standing machine base 1, and a sandbox assembly 5. The front of the floor-standing machine base 1 is provided with a positive pressure plate 2, a back pressure plate 3 and a back pressure plate Frame 4, the anti-pressure plate frame 4 is provided with a transverse slideway, the anti-pressure plate 3 slides on the transverse slideway, the rear end of the floor stand 1 is provided with a main oil cylinder frame 14, and the main oil cylinder 13 is fixed on the main oil cylinder frame 14. The pressure plate frame 4 and the main cylinder frame 14 are connected by four guide rods 11, the sand box assembly 5 slides back and forth in the guide of the guide rods 11, the piston rod extension end of the main cylinder 13 is vertically f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com