Gantry structure for laser cutting machine

A technology of laser cutting machine and gantry, which is applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of high precision, complex curved surface graphic material processing applications, low cutting efficiency and processing accuracy, etc., to achieve The effect of improving cutting efficiency and processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

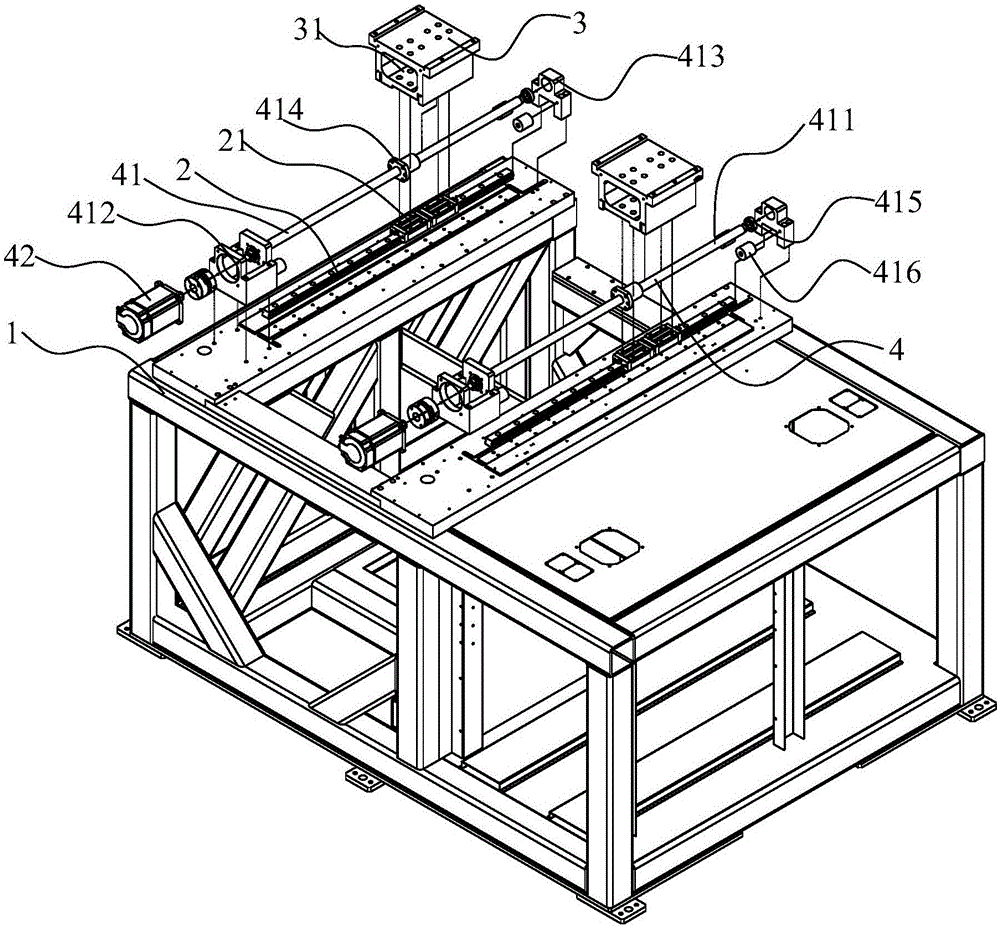

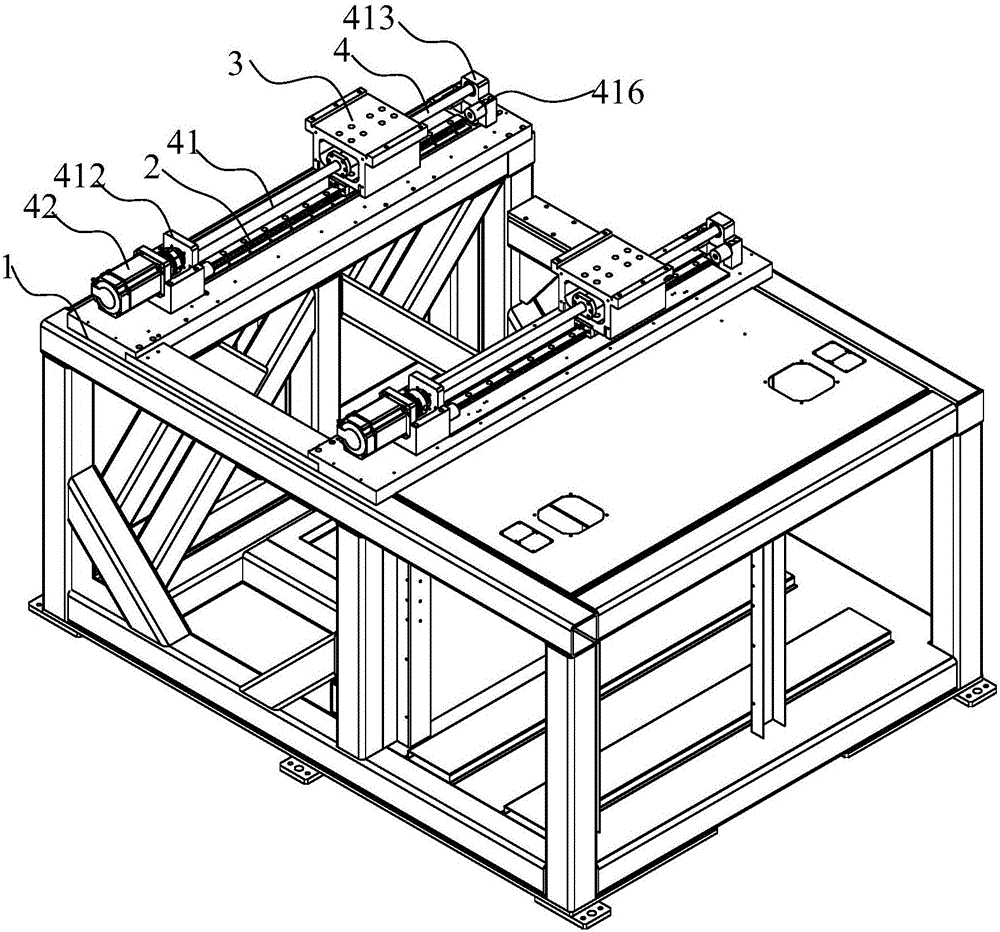

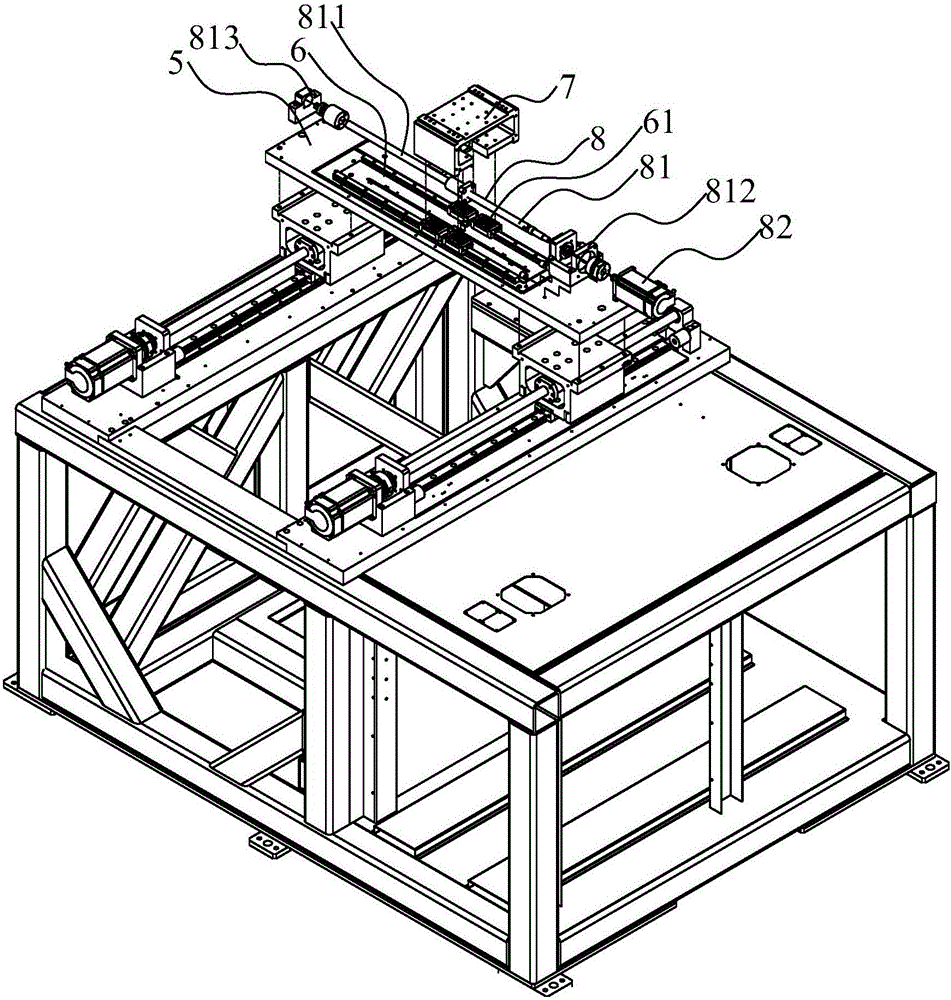

[0022] see figure 1 and figure 2 As shown, the embodiment of the present invention provides a gantry structure of a laser cutting machine, comprising: a main bed 1, two Y-axis guide rail groups 2, the two Y-axis guide rail groups 2 are arranged on the main bed body 1 in parallel with each other, and the guide rail groups There is a pair of Y-axis slide blocks 21; two Y-axis slide seats 3, the two Y-axis slide seats 3 are respectively arranged on the two Y-axis guide rail groups 2, and the Y-axis slide seats 3 are respectively arranged on the Y-axis of the Y-axis guide rail group 2 On the slider 21; two Y-axis sliding seats 3 are symmetrical along the center line of the two Y-axis guide rail groups 2; two Y-axis drive assemblies 4, each Y-axis drive assembly 4 is connected to a Y-axis sliding seat 3; Servo control device (not shown in the fig...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap