Multi-degree-of-freedom series-parallel polishing system

A degree of freedom and hybrid technology, applied in the direction of grinding/polishing equipment, surface polishing machine tools, grinding/polishing safety devices, etc., can solve problems such as instability, low efficiency, and surrounding environmental impact, and achieve grinding Stable quality, high grinding efficiency and quick response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

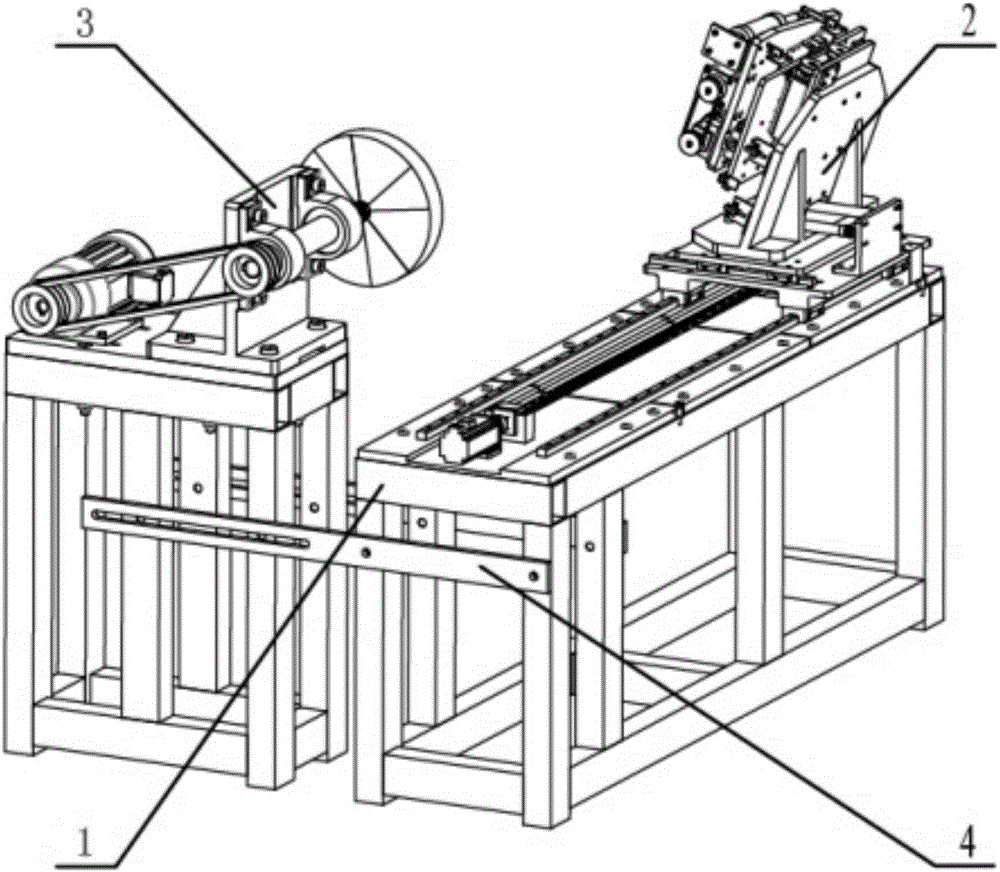

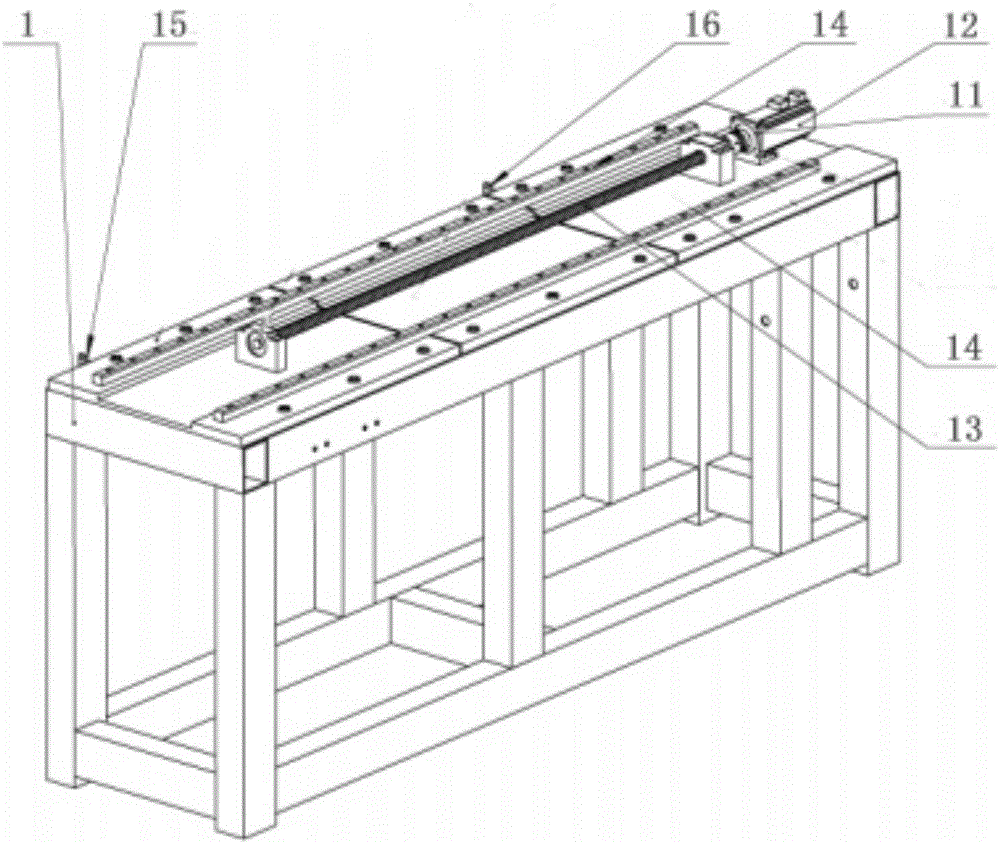

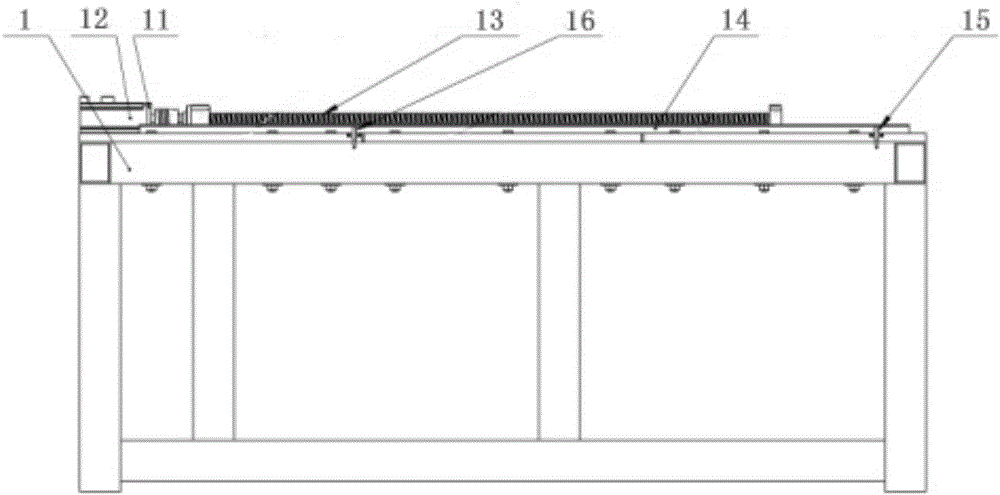

[0026] refer to Figure 1-Figure 9 , a multi-degree-of-freedom hybrid polishing system of the present invention includes a workbench 1, a clamping drive device 2 arranged on the workbench 1 for multi-angle movement of the workpiece, and a polishing device for polishing the workpiece Device 3, the workbench 1 is provided with a servo drive system 11 for driving the clamping drive device 2 in different positions to perform different process operations, and the clamping drive device 2 includes a clamping table for clamping and rotating the workpiece 21. The transverse sliding table 22 for driving the lateral movement of the clamping table 21, the longitudinal sliding table 23 for driving the horizontal sliding table 22 to move longitudinally together with the clamping table 21, and the drive for clamping according to the change of the surface shape of the workpiece itself Table 21, horizontal sliding table 22 and longitudinal sliding table 23 together perform rotary motion and li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com