Large steel tube stacking support and stacking method

A steel pipe, large-scale technology, applied in the field of steel pipe storage devices, can solve the problems of easy deformation, achieve the effect of reducing land use, simple bracket structure, and convenient manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

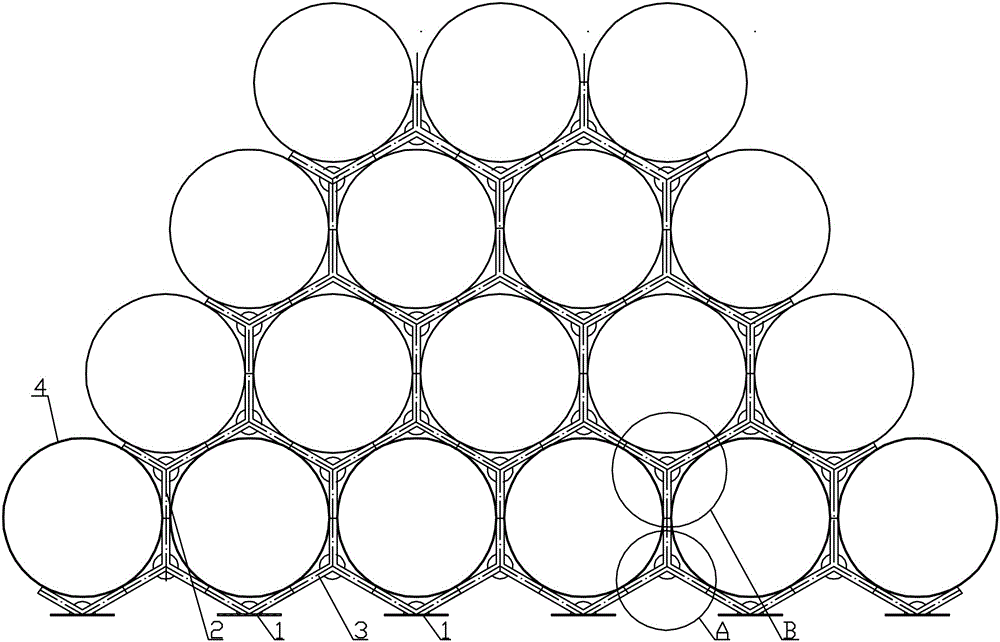

[0034] As shown in Figure 1-6, the large-scale steel pipe stacking bracket includes a base bracket 1, and the base bracket 1 is connected with the A-type intermediate bracket 2 and the B-type intermediate bracket 3 by plugging. The support 2 and the B-shaped intermediate support 3 are plugged together to form a multi-level grid-like frame.

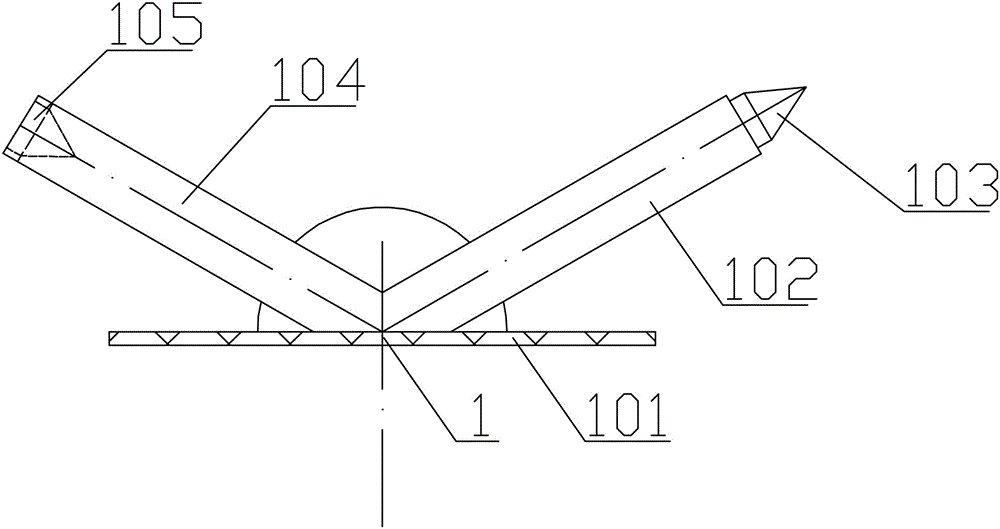

[0035] Further, the base bracket 1 includes a bottom plate 101, the top center of the bottom plate 101 is symmetrically provided with a left support rod 104 and a right support rod 102, the end of the left support rod 104 is processed with a first tapered hole 105, so The end of the right support rod 102 is processed with a first tapered end 103, and the included angles between the left support rod 104, the right support rod 102 and the bottom plate 101 are all 30°.

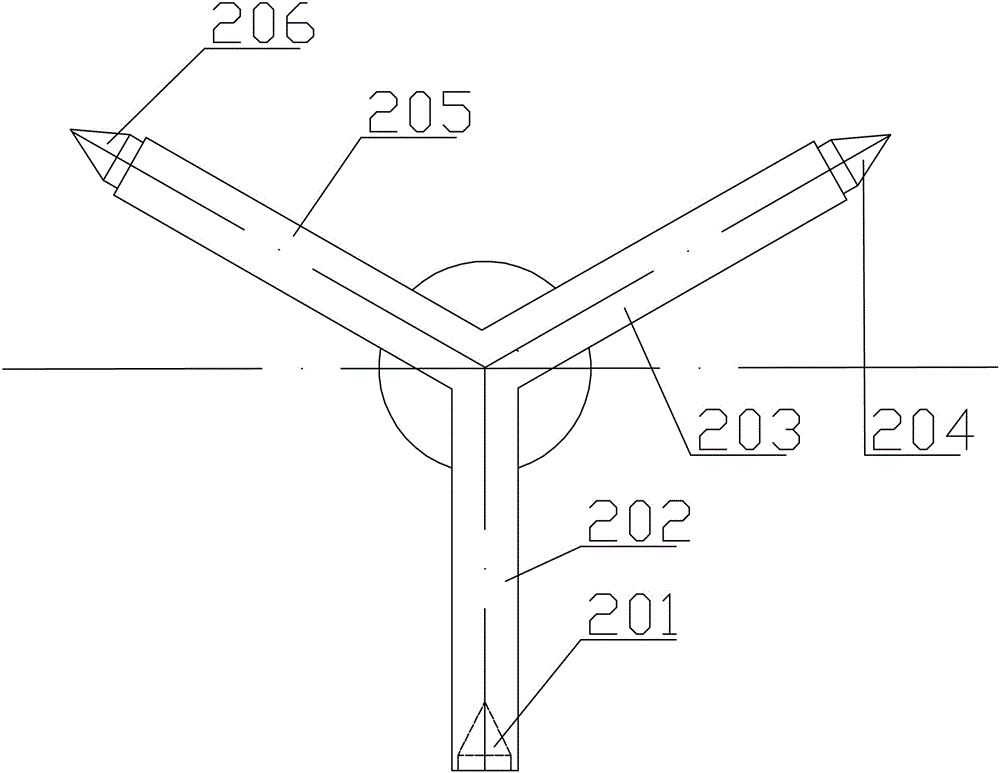

[0036] Further, the A-type intermediate support 2 is formed by cross-welding three evenly distributed A-type support rods 202, 203, 205, and the end of one of the A-type supp...

Embodiment 2

[0042] Introduce the concrete implementation steps of the present invention as follows in conjunction with legend 1-6:

[0043] 1. Make a simple and practical steel pipe stacking bracket

[0044] 1. When making large-scale penstocks for hydropower, first determine the height of the stacked steel pipes according to the site where the steel pipes can be stacked and the number of steel pipes, and then calculate and design the structural size of the stacked steel pipe supports according to the diameter, length, quantity and planned stacking height of the steel pipes, and select Materials used to make the bottom bracket, type A mid bracket and type B mid bracket.

[0045] 2. Make the support rods of the bottom bracket A-type intermediate bracket and B-type intermediate bracket. One end of the support rod is welded with a tapered end or a tapered hole to ensure that the tapered end and the tapered hole on the support rod are conveniently and firmly inserted into each other.

[0046...

Embodiment 3

[0049] 2. The practice of stacking steel pipes with brackets

[0050] 1. When stacking steel pipes 4, first ensure that the stacking site is flat and firm.

[0051] 2. Install the base bracket first, and then install the A-type intermediate bracket. The A-type intermediate bracket and the base bracket adopt a plug-in connection, that is, insert the tapered end (tapered hole) of the A-type intermediate bracket support rod into the tapered hole of the base bracket ( plug connector), after the installation of the A-type intermediate support on the first layer is completed, erect the bottom steel pipe;

[0052]3. After the bottom steel pipe is installed, install the B-type intermediate bracket and the A-type intermediate bracket in sequence by plugging in two layers, then erect the second layer of steel pipes, and so on, install the brackets, and erect the steel pipes; when erecting each layer of steel pipes, along the steel pipe Two sets of brackets can be placed in the length d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com