Kudzu rotary cutter

A technology of rotary cutting machine and kudzu root, applied in metal processing and other directions, can solve the problems of small flake area, difference in radius or width, affecting appearance quality, etc., and achieve the effect of uniform shape and size and small shape difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

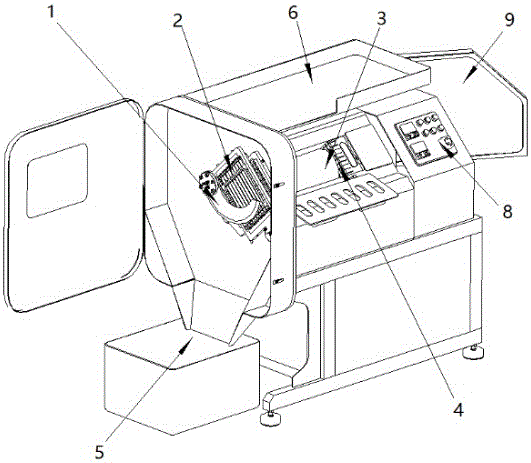

Image

Examples

Embodiment 1

[0025] Embodiment one (such as figure 1 Shown): A kudzu root rotary cutting machine, including: rotary machete 1, broaches 2, feed bin 3 and numerical control propulsion mechanism 4, the front end of feed bin 3 is numerical control propulsion mechanism 4, and the rear end of feed bin 3 is sequentially broach 2 And the machete 1, the direction of the cutting surface of the machete 1 is perpendicular to the direction of the cutting surface of the broach 2, the bottom of the machete 1 is the collecting tank 5, and the rotation axis of the machete 1 is located on the side of the discharge port of the silo 3, opposite to the discharge port The kudzu root is rotary cut, and the broach 2 is located in the discharge port of the feed bin 3, and the broach 2 is installed on the knife seat 21 that can move back and forth horizontally, and cuts the kudzu root vertically.

[0026] As a further specific description, the broach 2 includes two layers of blades 22, and the two layers of blades...

Embodiment 2

[0032] Embodiment 2: The difference from Embodiment 1 is that: as a further optimization, the broach 2 includes two layers of blades 22, and the blades 22 are perpendicular to each other.

Embodiment 3

[0033] Embodiment 3: The difference from Embodiment 1 is that the broach is divided into front and rear blades 22, and the front blade 22 and the rear blade 22 are perpendicular to each other.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap