Ventilating system for vehicle

A ventilation system and vehicle technology, applied in the field of vehicle ventilation systems, can solve the problems of low heat dissipation efficiency in the engine compartment, increased drag coefficient, and disordered airflow field, and achieve the effects of reducing the risk of heat damage, reducing wind resistance, and reducing the drag coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

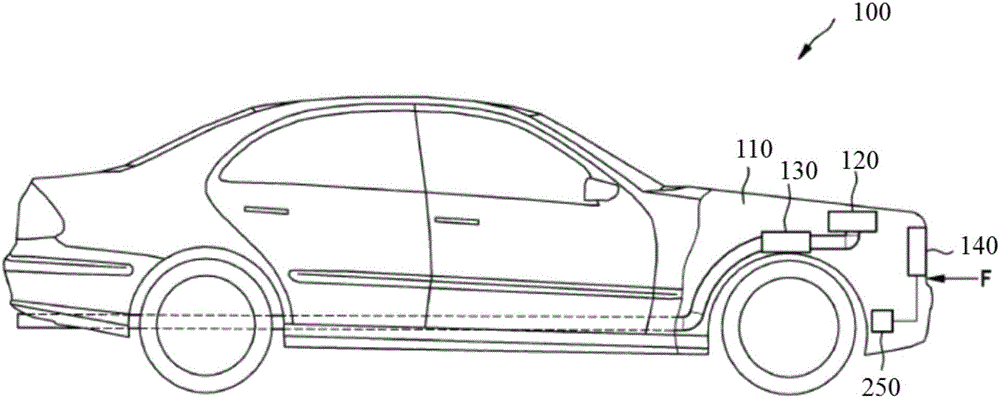

[0050] figure 1 Vehicle 100 is shown schematically with engine compartment 110 . Generally, one or more components that can dissipate heat when the vehicle 100 is running can be disposed in the engine compartment 110 , such as the internal combustion engine 120 and the exhaust device 130 . The internal combustion engine 120 exhausts combustion exhaust gas through an exhaust system 130 . The engine compartment 110 is basically closed, but there are gaps through which outside air can flow. The engine compartment 110 is generally located at the front of the vehicle 100, but is not limited thereto. The engine compartment 110 communicates with an air intake device 140 such as an air intake grill so that external air can flow through the engine compartment 110 as a headwind F.

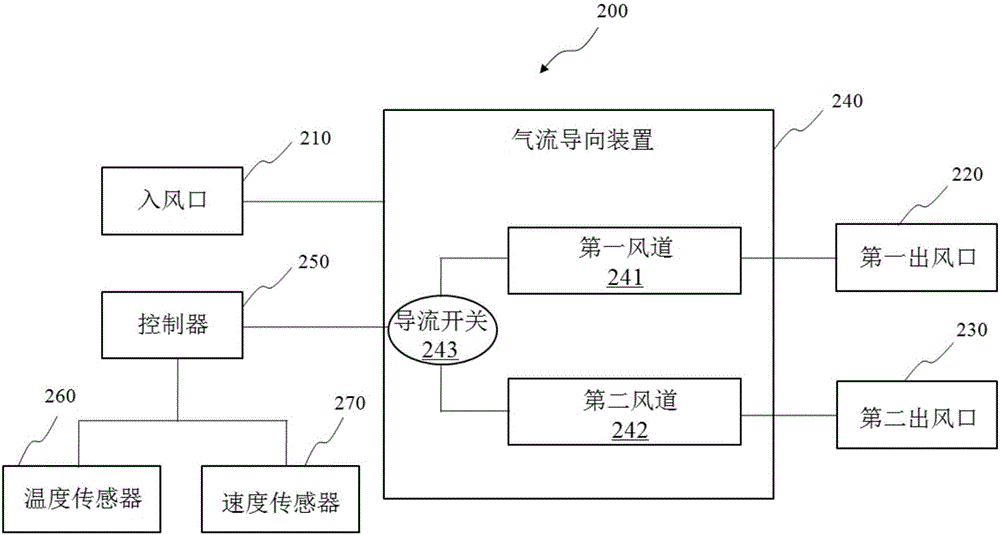

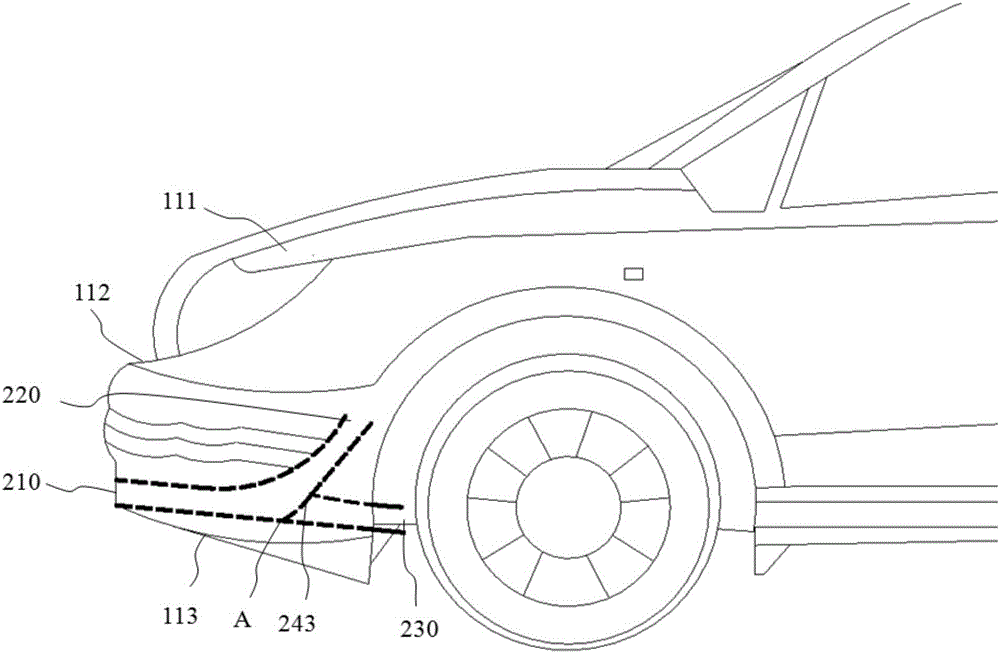

[0051] figure 2 A structural block diagram of a ventilation system 200 for a vehicle 100 according to an exemplary embodiment of the present invention is shown. image 3 and Figure 4A schematic side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com