Drag parachute housing with combined rear cover for aircraft

A combined, drag parachute technology, applied in aircraft parts, fuselage, parachutes, etc., can solve problems such as adverse effects on aircraft aerodynamic performance, and achieve the effects of simple structure, reduced flight resistance, and reduced probability of failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

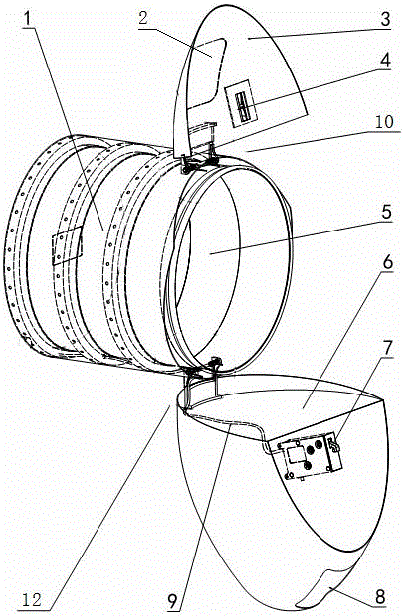

[0027] combined with Figure 1-4 Shown, a kind of aircraft resistance parachute cabin with combined back cover, comprises outer tube 1, inner tube 5, small cover shell 3, big cover shell 6, and described big cover shell 6 is provided with belt locking hook The electromagnetic unlocker 7, the small cover housing 3 is provided with a shaft pin 4, the lock hook on the electromagnetic unlocker 7 is adapted to the shaft pin 4, the electromagnetic unlocker 7 communicates with the cable 9, the The cable 9 is arranged between the outer cylinder 1 and the inner cylinder 5, the outer cylinder 1 and the inner cylinder 5 are connected by a Z-shaped rib provided on the inner cylinder, and the small cover housing 3 is hinged by the first support 10 On the inner cylinder 5 , the large cover housing 6 is hinged on the inner cylinder 5 through the second support 12 .

[0028] Technician packs resistance parachute in the present invention, manually closes large cover housing 6 and small cover ...

Embodiment 2

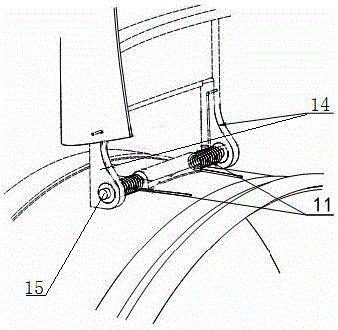

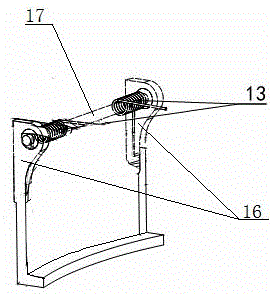

[0030] On the basis of Example 1, in conjunction with the attached Figure 1-4 As shown, the first support 10 includes a first support frame 14 and a first rotating shaft 15, the second support 12 includes a second support frame 16 and a second rotating shaft 17, and the first rotating shaft 15 and The second rotating shaft 17 is fixedly connected to the outer surface of the inner tube 5 respectively, and the first support frame 14 and the small cover housing 3, and the second support frame 16 and the large cover housing 6 pass through relatively The high-lock bolt connection with good shear resistance improves the fatigue resistance of the joint between the support frame and the shell, and enhances the durability and reliability of the components.

[0031] Further, a first torsion spring 11 is provided on the first rotating shaft 15, one end of the first torsion spring 11 is clamped on the small cover housing 3, and the other end is clamped on the outer surface of the inner c...

Embodiment 3

[0033] On the basis of embodiment 1 or 2, in conjunction with the attached Figure 1-4As shown, a first quick-release cover 2 is provided on the small cover housing 3 , and a second quick-release cover 8 is provided on the large cover housing 6 . When the present invention is maintained and maintained in the case of a power failure, the first quick release cover 2 on the small cover housing 3 and the second quick release cover 8 on the large cover housing 6 are removed, and the large cover shell is manually closed Body 6 and small cover housing 3, the lock hook on the electromagnetic unlocker 7 is inserted into the shaft pin 4 and locked automatically. The technician can check the locked situation from the first quick release port. If it is not automatically locked, it can be locked. Pull the lock hook of the electromagnetic unlocker 7 to lock it manually; when opening, those skilled in the art will put their hands into the large cover housing 6 through the second quick releas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com