High-effective movable sewage treatment device

A sewage treatment equipment, sewage treatment technology, applied in water/sewage treatment equipment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of poor mobility, poor applicability, simple process, etc. The effect of equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0030] The composition and function introduction of each module:

[0031] Energy supply module 8: divided into operation control area 8-1, power generation area 8-2 and fuel storage area 8-3. Operation control area 8-1: internally equipped with general power distribution cabinet, PLC control cabinet, monitoring computer and other facilities, used to control the operation and management of the whole set of mobile sewage treatment equipment; power generation area 8-2: for some remote areas that do not have power supply conditions In the region, the use of self-provided generators can effectively ensure the energy supply of sewage treatment equipment; fuel storage area 8-3: used to ensure the fuel used by generators, mainly diesel oil storage.

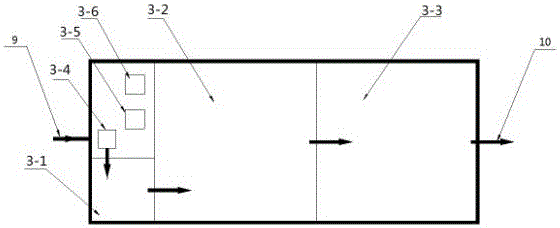

[0032] Pretreatment module 3: The sewage passes through the grid area 3-1, the primary sedimentation area 3-2, and the primary strengthening area 3-3 in sequence for pretreatment. The grid area 3-1 mainly removes large-grained inorganic ...

Embodiment 1

[0065] Embodiment 1: High-efficiency mobile sewage treatment equipment mainly includes an energy supply module 8, a pretreatment module 3, a chemical treatment module 4, a biological treatment module 5, a sedimentation filtration module 6, and an advanced treatment module 7. The energy supply module 8 is operated by Composed of a control area 8-1, a power generation area 8-2 and a fuel storage area 8-3; the pretreatment module 3 is mainly composed of a grid area 3-1, a primary sedimentation area 3-2 and a primary strengthening area 3-3 connected in series Composition; the chemical treatment module 4 is mainly composed of a drug storage area 4-1, a pH adjustment area 4-2, a reaction precipitation area 4-3 and an oxidation / reduction area 4-4; the biological treatment module 5 is mainly composed of an anaerobic Oxygen zone 5-1, anoxic zone 5-2 and aerobic zone 5-3; said precipitation filtration module 6 mainly includes two parts of precipitation zone 6-1 and filtration zone 6-2; s...

Embodiment 2

[0067] Embodiment 2: High-efficiency mobile sewage treatment equipment mainly includes an energy supply module 8, a pretreatment module 3, a chemical treatment module 4, a biological treatment module 5, a sedimentation filtration module 6, and an advanced treatment module 7. The energy supply module 8 is operated by Composed of a control area 8-1, a power generation area 8-2 and a fuel storage area 8-3; the pretreatment module 3 is mainly composed of a grid area 3-1, a primary sedimentation area 3-2 and a primary strengthening area 3-3 connected in series Composition; the chemical treatment module 4 is mainly composed of a drug storage area 4-1, a pH adjustment area 4-2, a reaction precipitation area 4-3 and an oxidation / reduction area 4-4; the biological treatment module 5 is mainly composed of an anaerobic Oxygen zone 5-1, anoxic zone 5-2 and aerobic zone 5-3; said precipitation filtration module 6 mainly includes two parts of precipitation zone 6-1 and filtration zone 6-2; s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com