A kind of polysiloxane with electrochromic performance and preparation method thereof

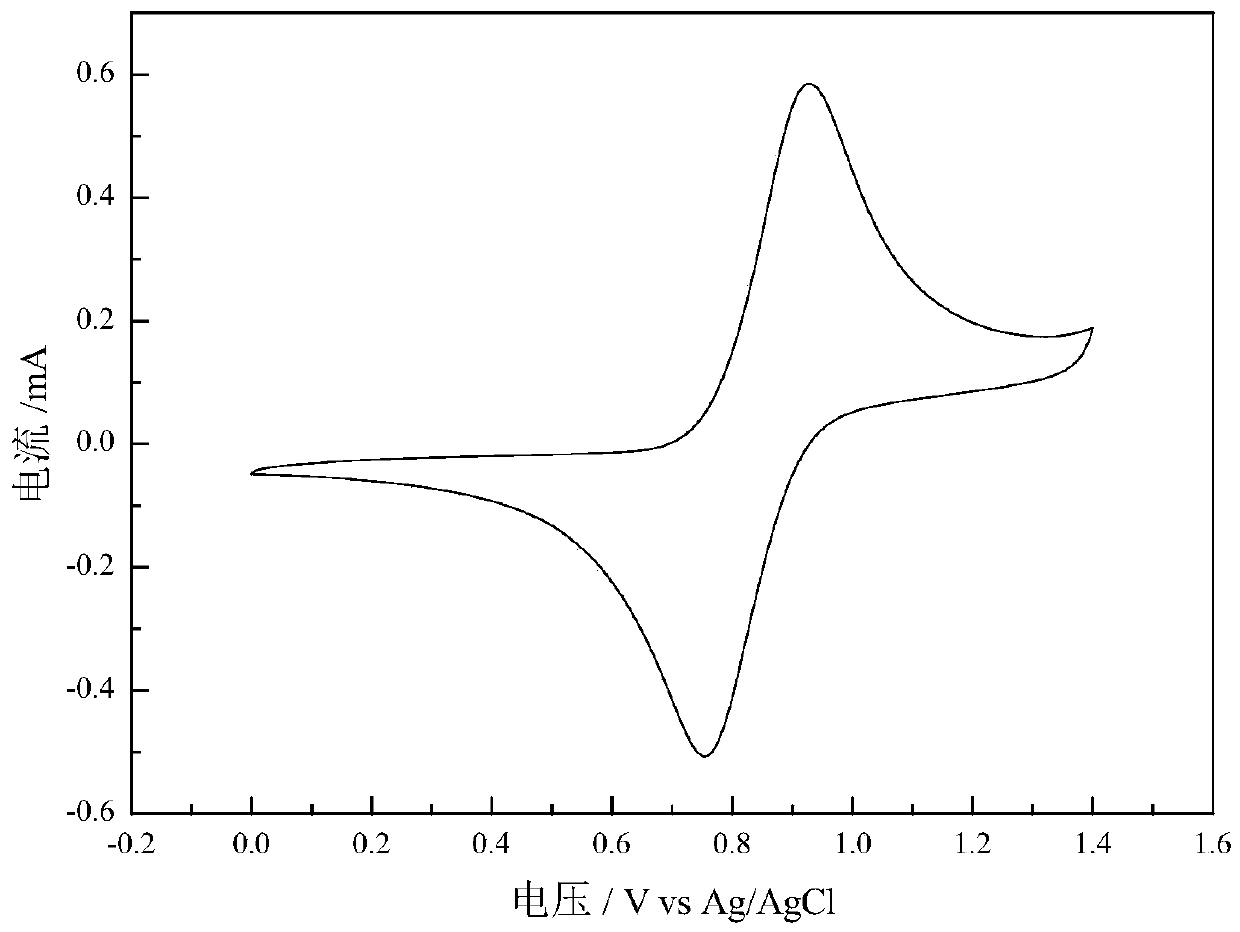

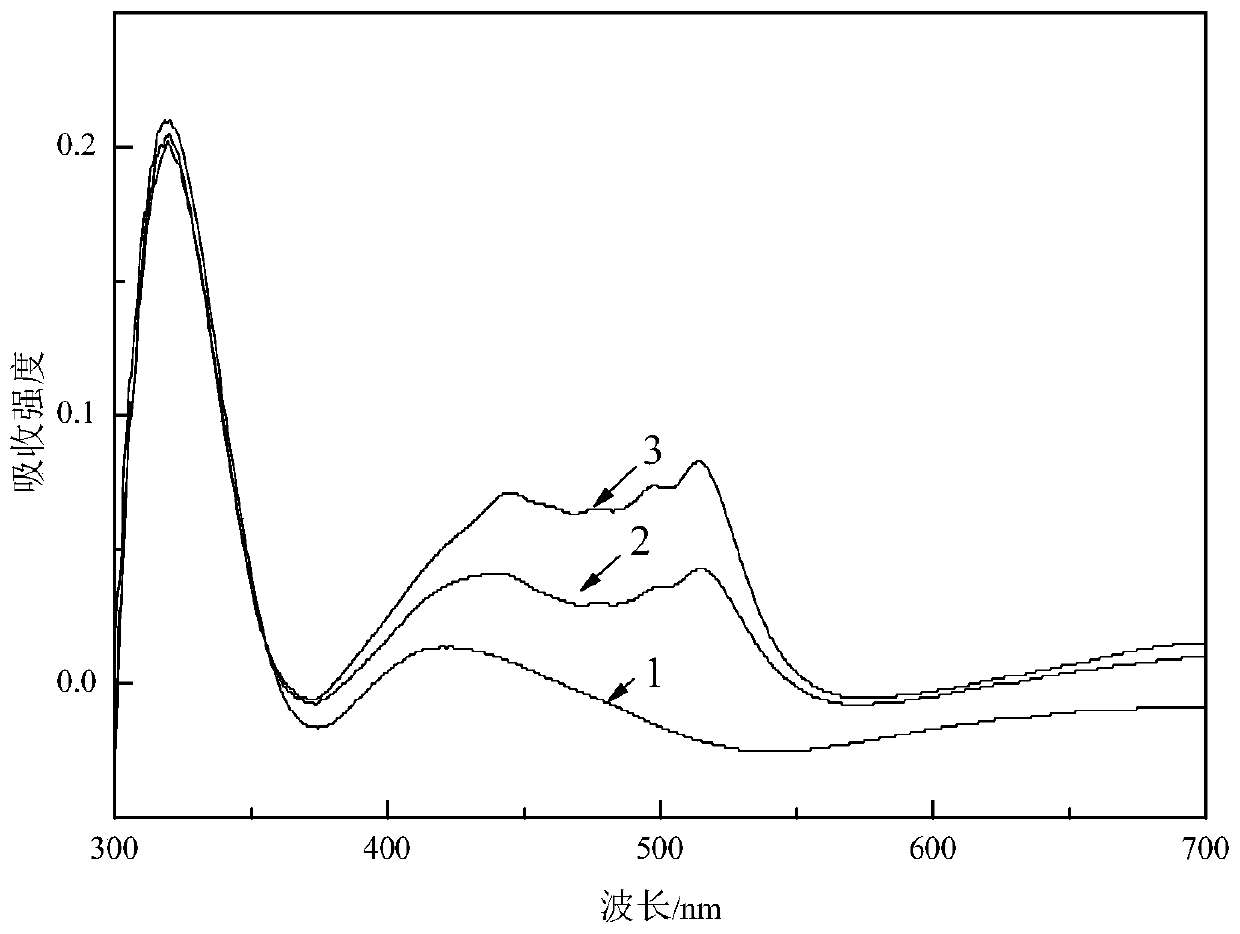

A polysiloxane, electrochromic technology, applied in the preparation of organic compounds, the preparation of carboxylic acid amides, chemical instruments and methods, etc. Effects of stability, good electrochemical redox reversibility, and high cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

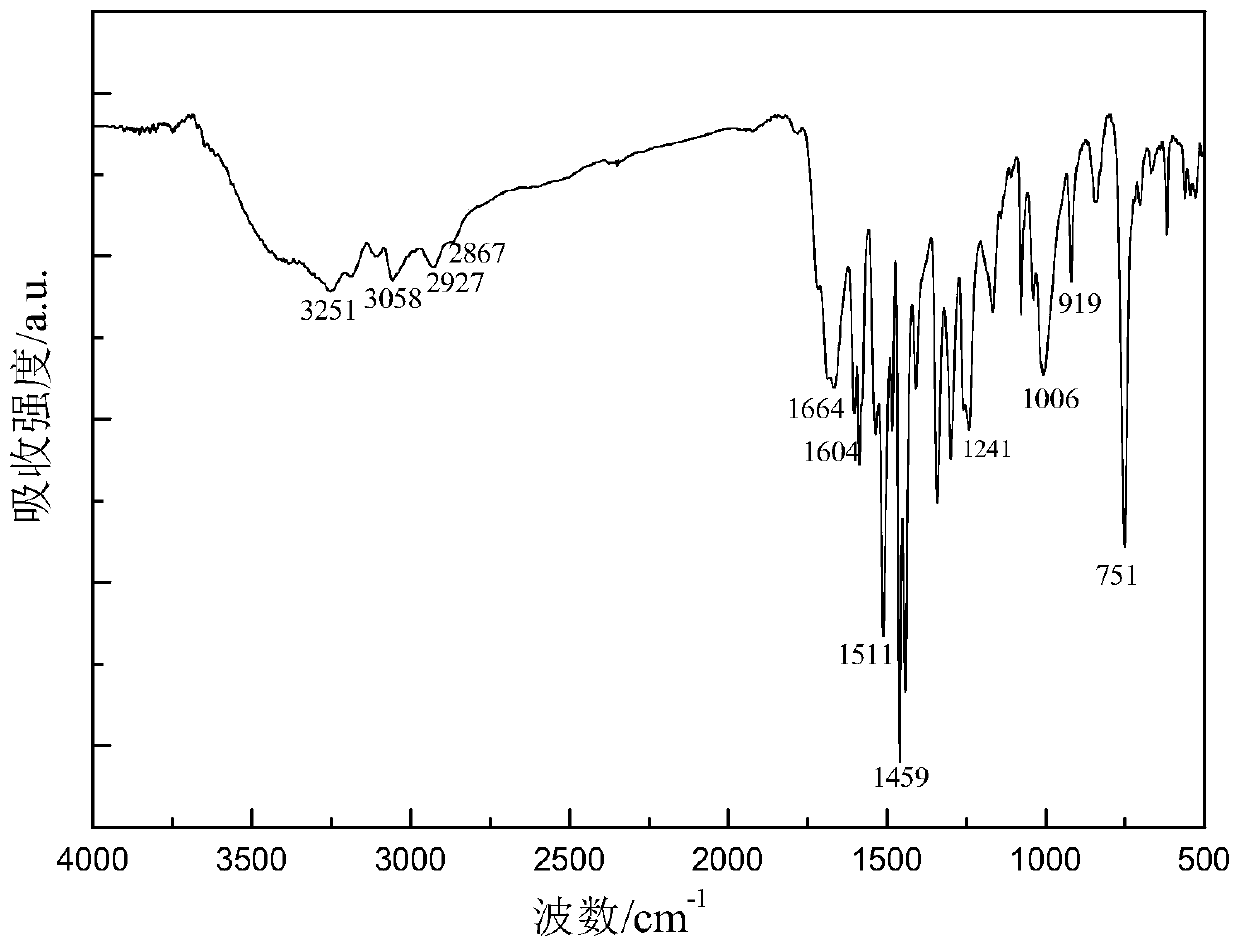

[0061] Specific embodiment 1: This embodiment is a polysiloxane with electrochromic properties. The structural formula is:

[0062] where R is

[0063] The value range of n is 1≤n≤10000, the value range of m is 1≤m≤10000, and both m and n are integers.

specific Embodiment approach 2

[0064] Specific embodiment two: This embodiment is a method for preparing polysiloxane with electrochromic properties, which is specifically completed according to the following steps:

[0065] 1. Synthetic monomer:

[0066] ①. Dissolve an aminoaniline derivative in N,N-dimethylformamide, and then stir at a stirring speed of 200r / min~500r / min for 20min~40min to obtain a clear transparent solution;

[0067] The volume ratio of the amount of an aminoaniline derivative described in step 1. to N,N-dimethylformamide is 5mmol:100mL;

[0068] ②. Add triethylamine to the clear transparent solution, and then stir for 3 minutes to 5 minutes at a stirring speed of 200r / min to 500r / min to obtain a mixed solution I;

[0069] The mol ratio of triethylamine described in step 1.2 and an aminoaniline derivative in the clear transparent solution is 1:1;

[0070] ③. Dissolving acryloyl chloride in N,N-dimethylformamide to obtain acryloyl chloride solution;

[0071] The volume ratio of the amo...

specific Embodiment approach 3

[0096] Specific embodiment three: the difference between this embodiment and specific embodiment two is: the one-aminoaniline derivative described in step one ① is 4-aminotriphenylamine, 4-aminophenyl-N-carbazole, 4- Aminophenyl-N-phenothiazine, 4-amino-4',4"-di-tert-butyltriphenylamine, 4-amino-4',4"-dimethoxytriphenylamine or N-(β-naphthalene base)-N-phenyl-p-phenylenediamine. Others are the same as in the second embodiment.

[0097] The structural formula of the 4-aminophenyl-N-phenothiazine described in this embodiment is The structural formula of described 4-amino-triphenylamine is The structural formula of the described 4-amino-4', 4 "-di-tert-butyltriphenylamine is: The structural formula of the N-(β-naphthyl)-N-phenyl-p-phenylenediamine is: The structural formula of described 4-aminophenyl-N-carbazole is The structural formula of described 4-amino-4',4 "-dimethoxytriphenylamine is

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com