Tubular cracking furnace

A tubular cracking furnace and furnace lining technology, used in cracking, hydrocarbon cracking to hydrocarbon production, non-catalytic thermal cracking, etc. Increase the rate of cracking reaction, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing.

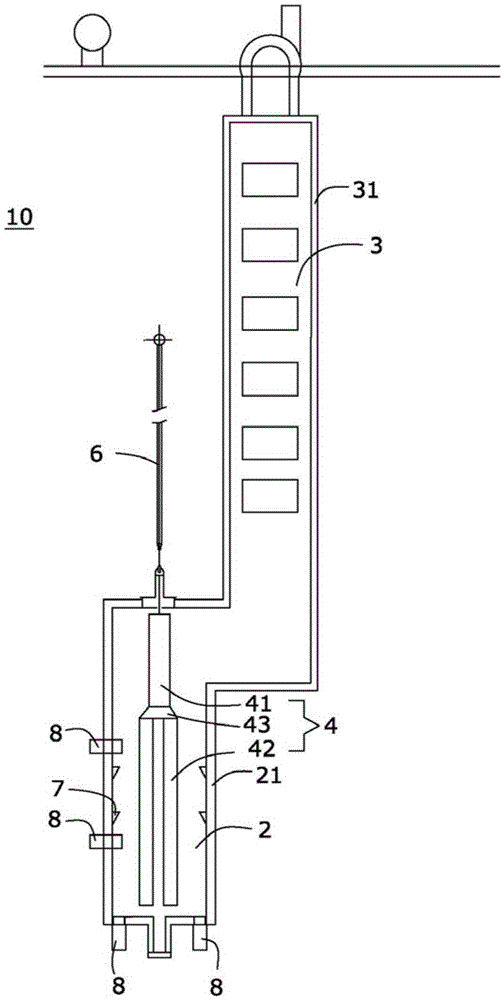

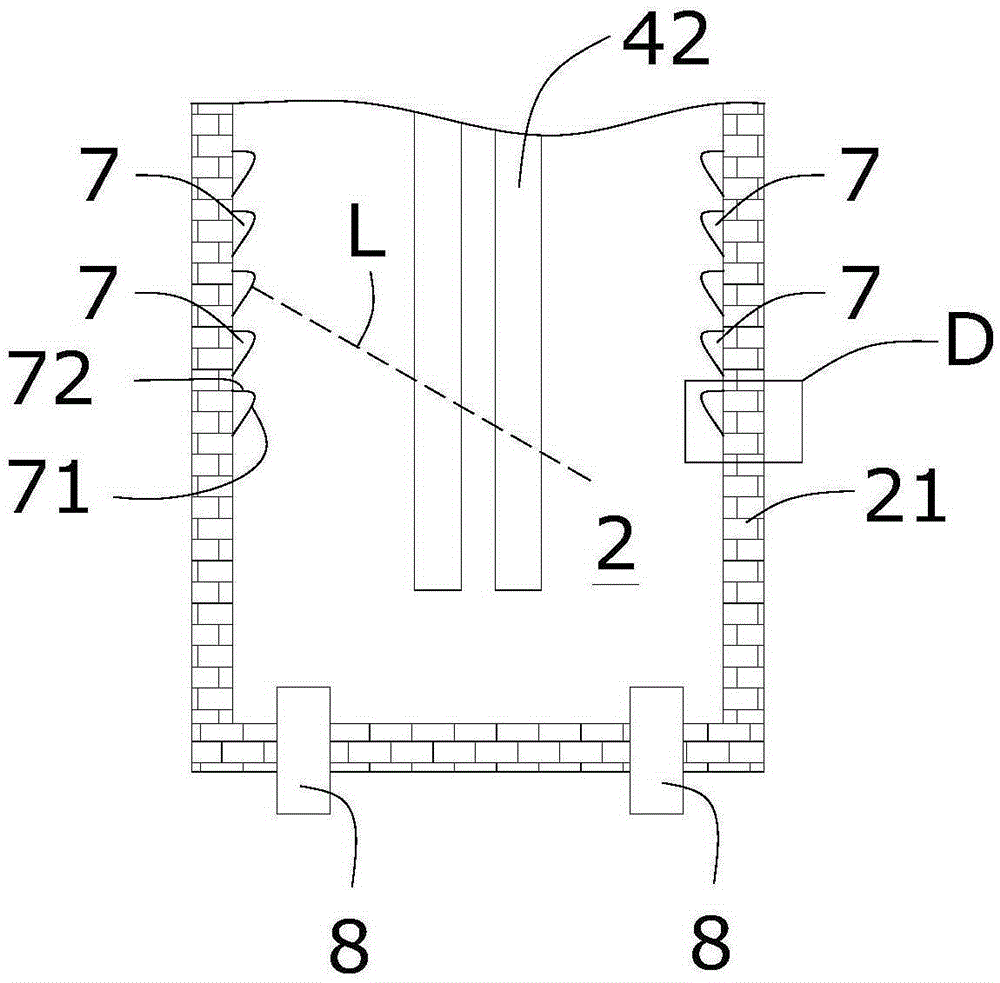

[0031] figure 1 It is a structural schematic diagram of the tubular cracking furnace 10 according to the present invention. The tubular cracking furnace 10 is mainly used for heating various cracking raw materials such as natural gas, refinery gas, crude oil and naphtha, so as to promote the carbon chain breaking chemical reaction of the cracking raw materials to generate low-carbon hydrocarbons such as ethylene, propylene and / or butadiene. Carbene and various by-products.

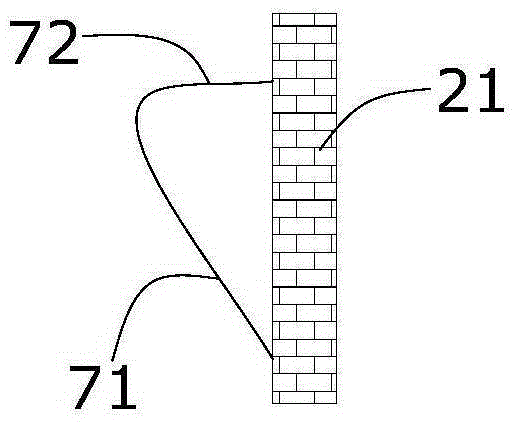

[0032] Such as figure 1 As shown, the tube cracking furnace 10 includes a radiation chamber 2, a convection chamber 3 connected to the radiation chamber 2 and staggered higher than the radiation chamber 2, and a furnace tube assembly 4 arranged in the radiation chamber 2, located on the top of the radiation chamber 2 A quenching boiler 6 (a conventional product in the field) above and communicated wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com