Heat field structure for growth of low-dislocation single crystals by czochralski method and growing process of single crystal

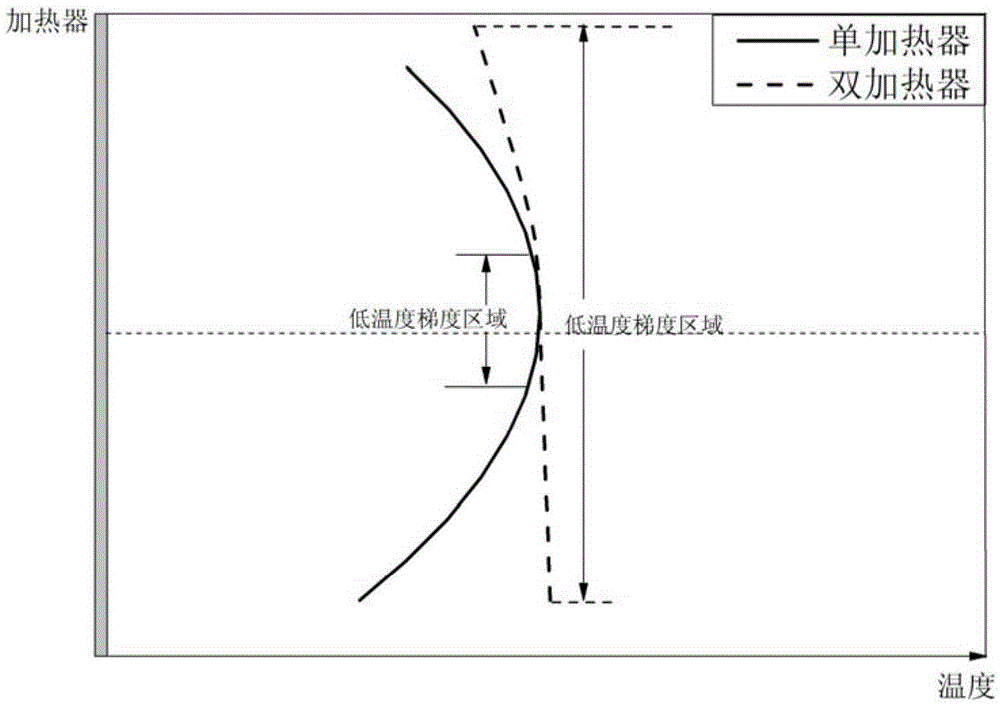

A technology of low dislocation and Czochralski method, which is applied in the directions of crystal growth, single crystal growth, self-melt pulling method, etc., can solve the problems of large temperature gradient and small range of low temperature gradient area, and achieve the reduction of temperature gradient and increase of Large and low temperature gradient area, the effect of lengthening the effective length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

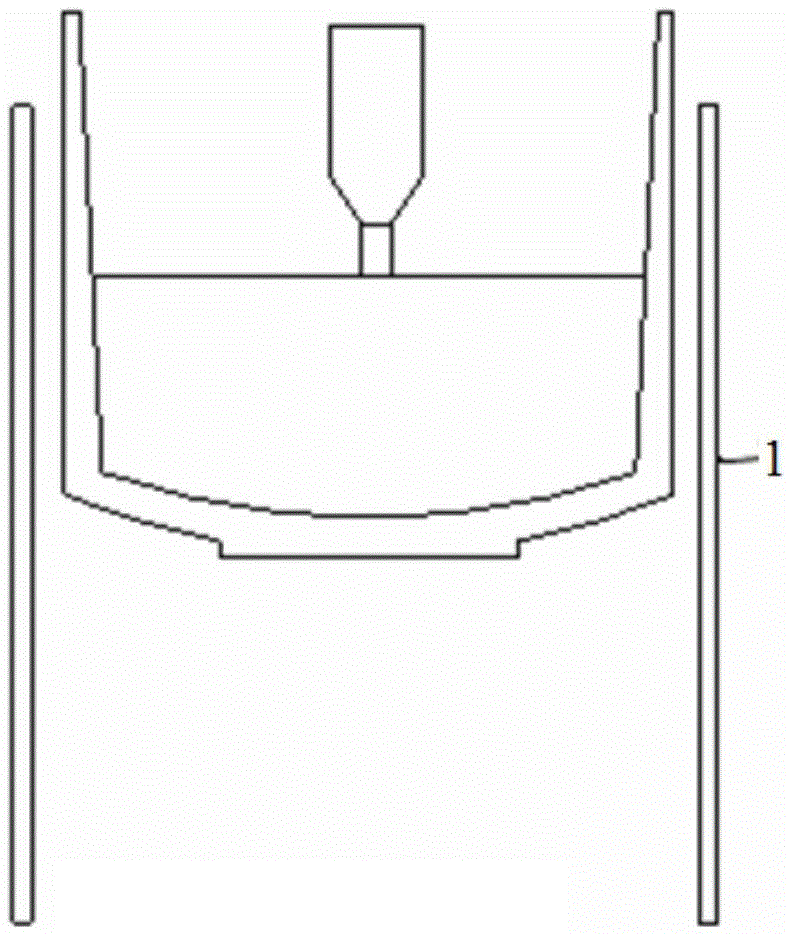

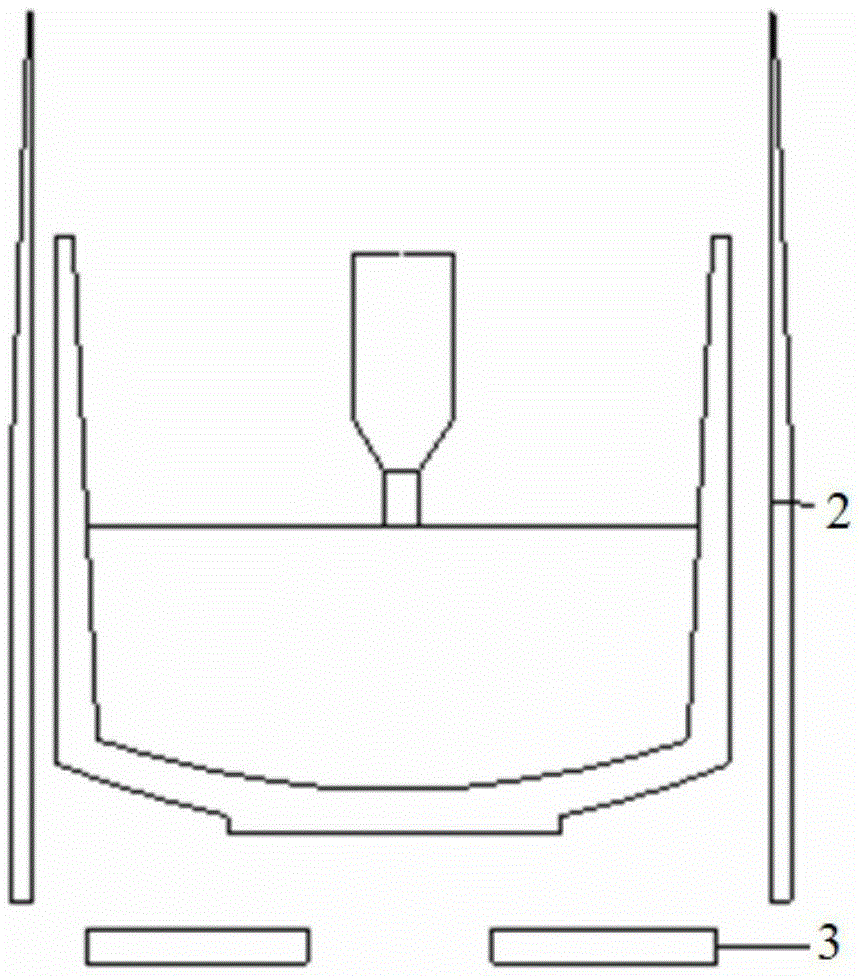

Image

Examples

Embodiment

[0027] Change the heat field structure in comparative example 1 into the heat field structure of the present invention, during materialization, main heater power is about 42kw; Bottom heater power is about 10kw; At this moment in main heater (diameter and length and comparative example 1 The single heater is the same as the upper edge of about 1 / 4 of the length of about 450mm below the range of about 450mm, near the melting point of germanium at 937°C, the available temperature gradient is reduced to below 0.3k / cm, and the power of the heater before seeding is stable for 6-10 hours , use seed crystal and melt fusion directly at the low crucible position (low temperature gradient area), observe the method of solid-liquid interface change state when the seed crystal contacts the melt, find the seeding temperature, and then seed the crystal at the seeding temperature for about Put it directly on the shoulder after 1 hour, and use the industrial programmable controller to independe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap