Preparation method of perovskite single crystals

A perovskite and single crystal technology is applied in the field of preparation of perovskite single crystals, which can solve the problems of long time consumption, low solution utilization rate, and large number of crystal nuclei of perovskite single crystals, so as to reduce the number of fine crystal nuclei, The effect of improved utilization and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

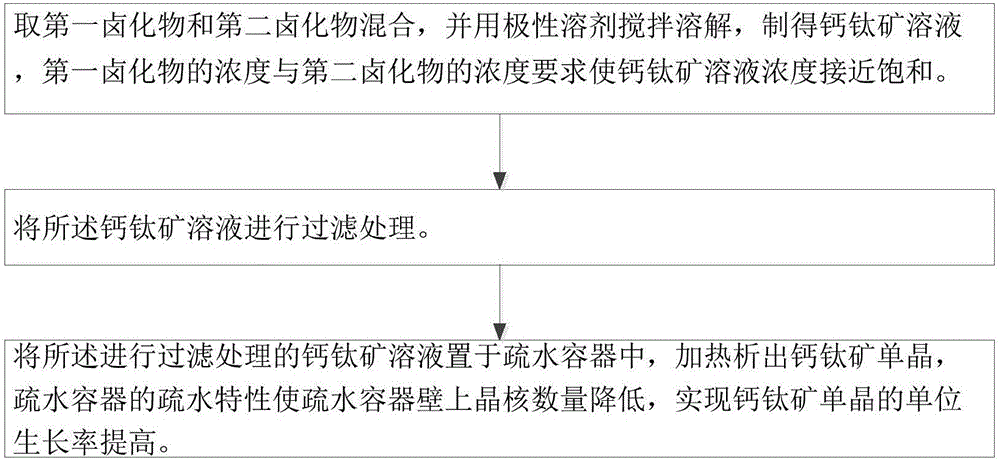

[0027] The first embodiment of the preparation method of the perovskite single crystal provided by the present invention, its specific preparation steps are as follows:

[0028] (1) Weigh 1.59g of methylamine iodide (CH 3 NH 3 I, MAI) and 3.688g lead iodide (PbI 2 ), dissolved in 10mL of γ-butyrolactone (GBL), stirring and dissolving at 60°C for 12-24h to obtain a perovskite solution;

[0029] (2) Filter the perovskite solution with a 0.45 μm filter head;

[0030] (3) Clean the PTFE container with deionized water for 10 minutes, clean the PTFE container with acetone for 10 minutes, clean the PTFE container with isopropanol for 10 minutes, clean the PTFE container with deionized water for 10 minutes, and then dry it with a nitrogen gun;

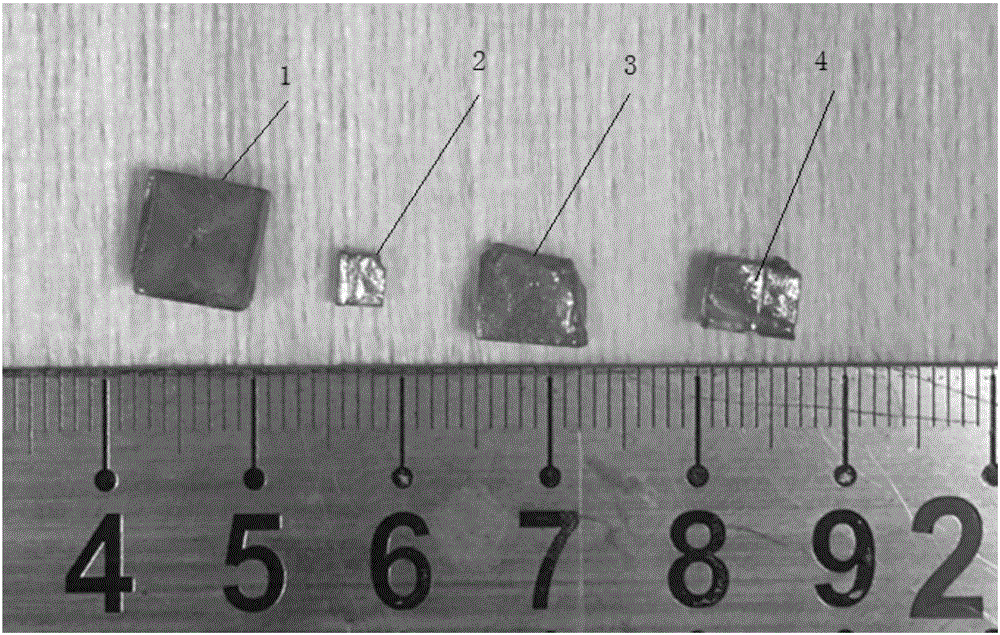

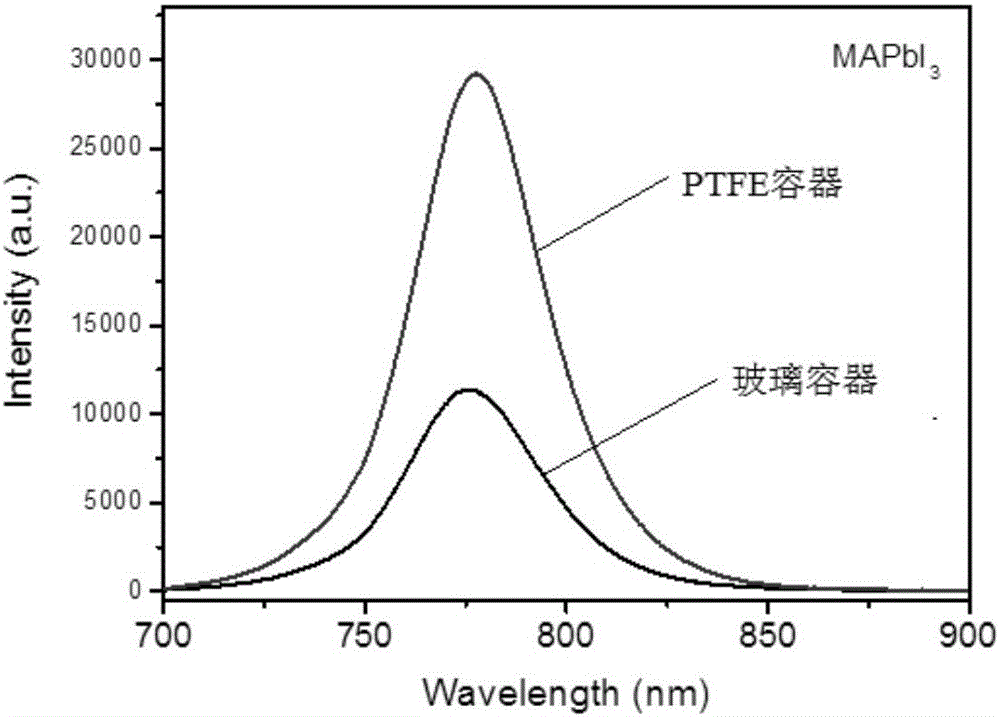

[0031] (4) Take 10mL of the filtered perovskite solution and carefully place it in a PTFE container, heat it on a heating platform at 100°C to slowly evaporate the solvent, the perovskite solution reaches supersaturation, and the crystals g...

no. 4 example

[0043] The fourth embodiment of the preparation method of the perovskite single crystal provided by the present invention, its specific preparation steps are as follows:

[0044] (1) Weigh 1.12g of methyl bromide (CH 3 NH 3 Br) and 3.688g lead bromide (PbI 2 ), dissolved in 10mL of N,N-dimethylformamide (DMF) and γ-butyrolactone (GBL) mixed solution, the volume ratio of N,N-dimethylformamide and γ-butyrolactone is 2:8, stirring and dissolving at 60°C for 12-14h to obtain a perovskite solution;

[0045] (2) Obtain the perovskite solution by filtering with a 0.45 μm filter head;

[0046] (3) Clean the PTFE container with deionized water for 10 minutes, clean the PTFE container with acetone for 10 minutes, clean the PTFE container with isopropanol for 10 minutes, clean the PTFE container with deionized water for 10 minutes, and then dry it with a nitrogen gun;

[0047] (4) Take 10mL of the filtered perovskite solution and place it in a PTFE container, place it on a heating pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com