Method for connecting steel beams and laminated slabs

A connection method and a technology of laminated panels, which are applied in the direction of construction and building construction, can solve the problems of increasing manpower, material resources, and financial resources, high requirements for construction quality, and increased construction costs, and achieve high processing accuracy, easy quality, and energy saving The effect of engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described in detail below with reference to accompanying drawing and embodiment:

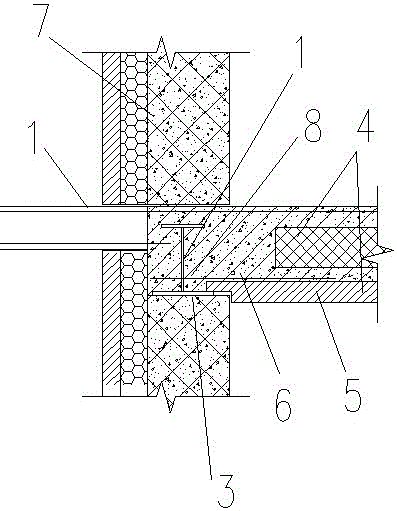

[0032] attached Figure 1-2 It can be seen that a method for connecting steel beams and laminated slabs,

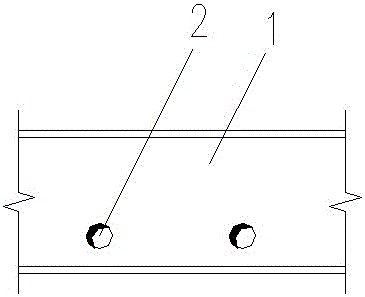

[0033] Open a round hole 2 on the steel beam web 1;

[0034] A prefabricated laminated hollow floor slab 4 is erected on the upper surface of the lower flange 3 of the steel beam;

[0035] On the top of the prefabricated layer 5 of the prefabricated laminated hollow floor slab 4, lay laminated slab reinforcing bars 6 along the horizontal direction;

[0036] The end of the laminated slab reinforcing bar 6 protrudes from the end of the prefabricated laminated hollow floor slab 4;

[0037] The end of the laminated steel bar 6 passes through the round hole 2 opened on the web of the steel beam;

[0038] Prefabricated laminated hollow-core slabs and steel beams are cast-in-place;

[0039] Concrete is poured on the surface of the prefabricated laminated hollow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com