Assembly type thermal-insulating wall body construction structure

A thermal insulation wall and prefabricated technology, which is applied in the direction of walls, building components, building structures, etc., can solve the problems of large engineering volume, long construction period, and inconvenient connection, etc., and achieve enhanced stability, good thermal insulation effect, and stable laying Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with embodiment the present invention is further described in detail.

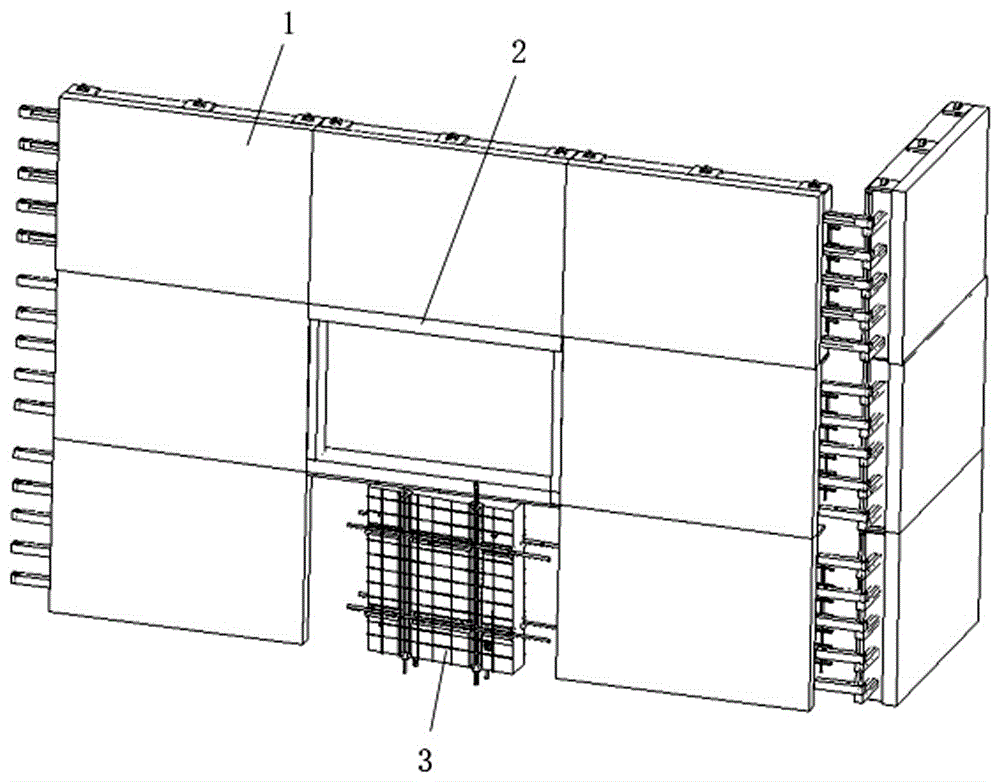

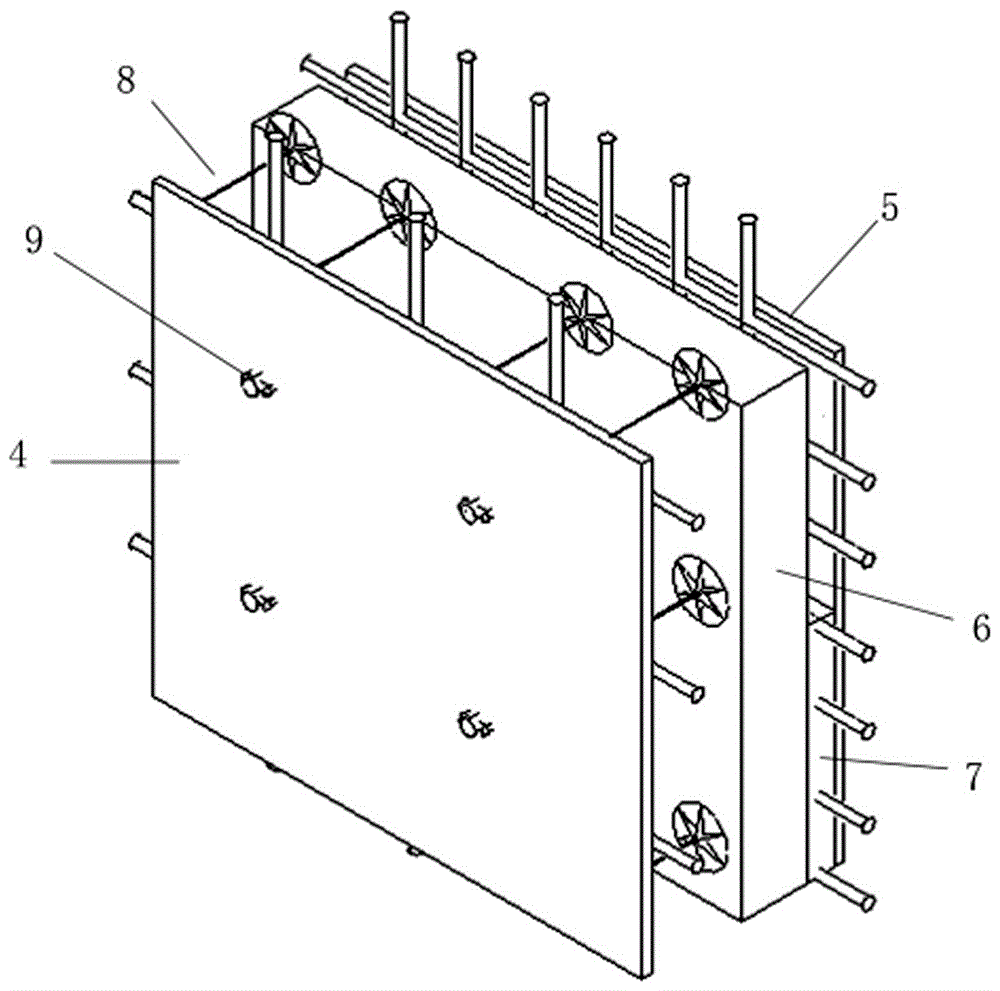

[0021] like Figure 1 to Figure 6 As shown, a kind of prefabricated thermal insulation wall construction structure comprises a structural wall 1, a window sill frame 2 and a filling wall 3; the structural wall 1 includes an inner template 4, an inner mortar layer 8, an insulation board 6, an outer mortar layer 7 and The outer template 5, the inner mortar layer 8 and the outer mortar layer 7 are provided with a reinforcement layer 8; the inner mortar layer 8, the outer mortar layer 7 and the insulation board 6 are provided with a cross-shaped positioning member 9;

[0022] The structural walls 1 are arranged and connected vertically and horizontally, the window sill frame 2 is arranged between the structural walls 1, and the filling wall 3 is installed at the position below the window sill frame 2;

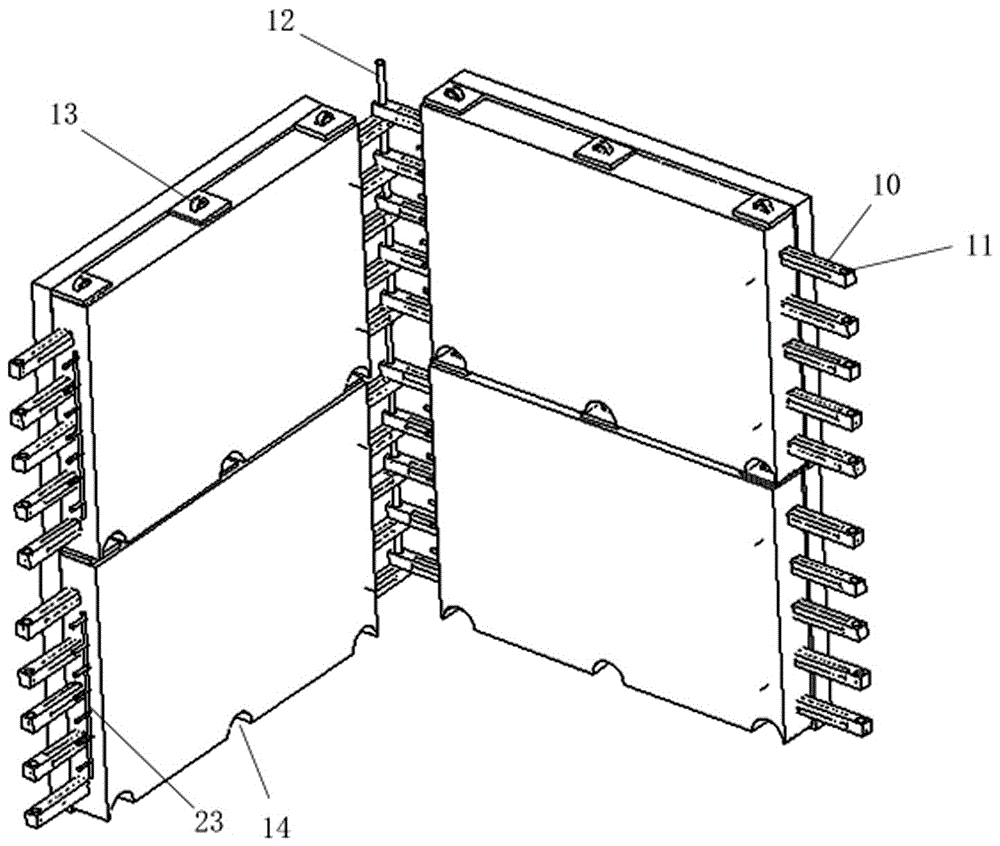

[0023] The left and right sides of the structural wall 1 are provided with over...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com