Built-in X-shaped opposite-pulling steel plate type welded rectangular concrete filled steel tubular column and construction method

A technology for rectangular steel pipe and concrete columns, applied in the direction of columns, pier columns, pillars, etc., can solve the adverse effects of welded rectangular steel pipe concrete columns on bearing capacity, interface cohesion and durability, core concrete bulging, cracks and temperature Deformation, reduction of core concrete confinement effects, etc., to avoid "X"-shaped cracks, improve anti-slip performance, and save materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described in detail with reference to accompanying drawing:

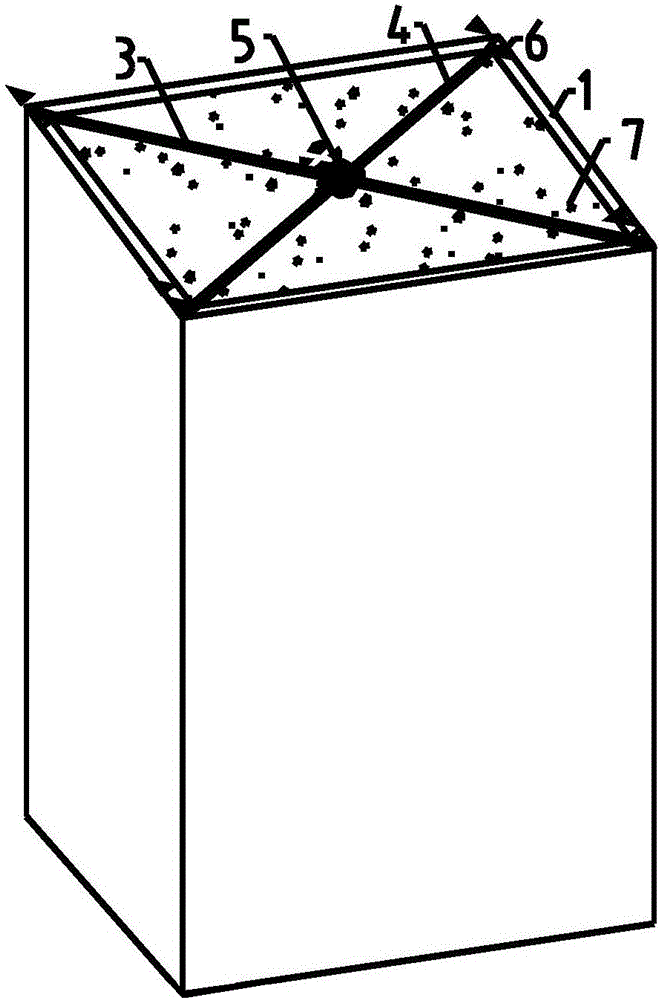

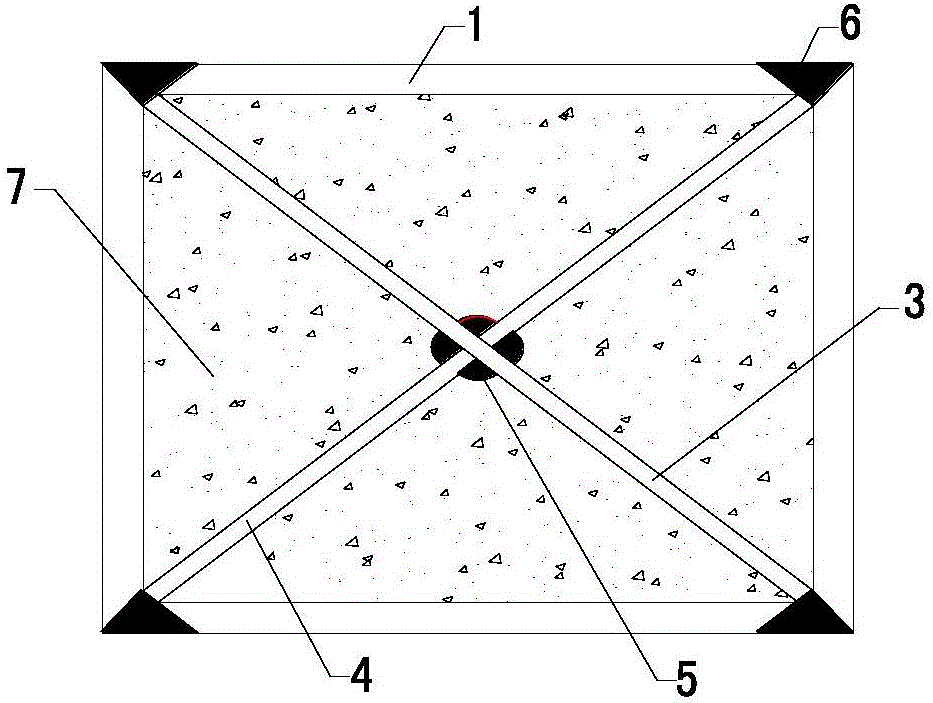

[0035] like Figure 1 to Figure 6 As shown, a built-in X-shaped double-tensioned steel plate type welded rectangular steel tube concrete column, which includes welded rectangular steel pipe 1, X-type double-tensioned steel plate 2 and core concrete 7; Pouring core concrete 7 in the space.

[0036] The welded rectangular steel pipe 1 is a steel pipe with a rectangular cross section welded by four steel plates.

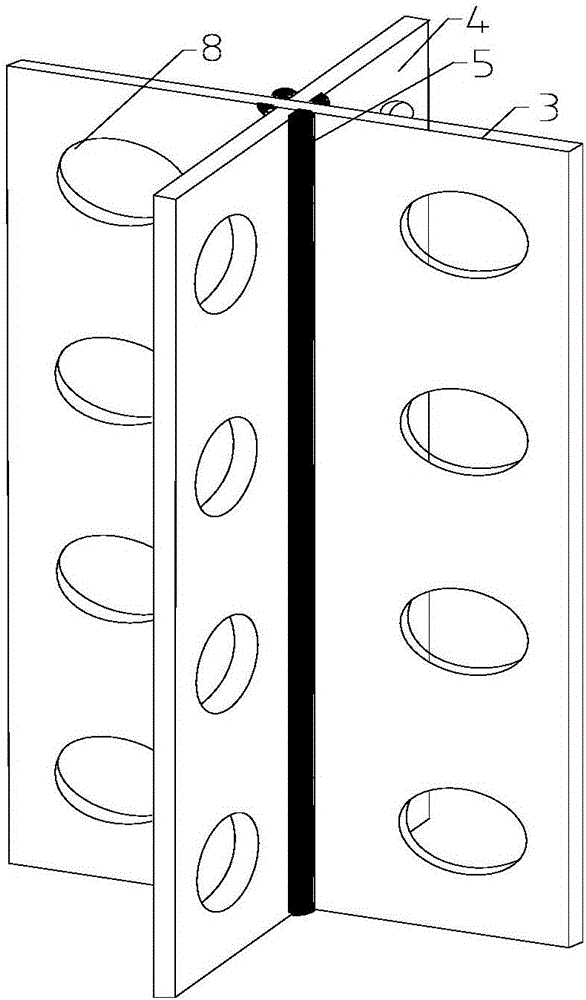

[0037] The X-shaped double-drawn steel plate 2 is a steel structural member with an X-shaped cross-section welded by a main steel plate 3 and two auxiliary steel plates 4; the device includes two X-shaped double-drawn steel plates 2, and the height is longitudinally welded rectangular steel pipes 1 / 4 of the net height of the concrete column is set at both ends of the column respectively; the shear bearing capacity at both ends of the column is strengthened, and the circular h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com