Assembled building door/window installation structure

A technology for building doors and windows and installation structures, which is applied to building components, building structures, buildings, etc. It can solve the problems of low installation efficiency, cumbersome installation, and inability to realize prefabricated installation, and achieve fast installation, improved waterproof performance, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

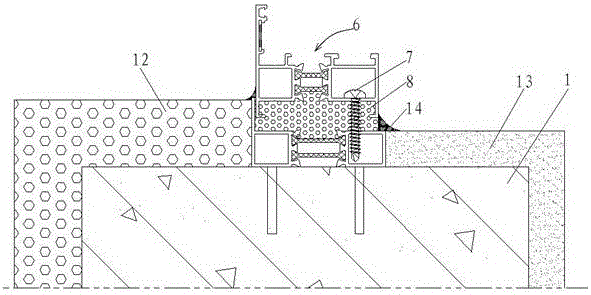

[0020] Such as figure 1 , 2 The door and window installation structure of the prefabricated building shown in 3 includes a prefabricated wall 1, a door and window hole 2 is reserved on the wall 1, a subframe 3 is fixed around the door and window hole 2, and a fixing part is provided at the bottom of the subframe 3 4 is pre-buried in the wall 1, the outer wall of the sub-frame 3 is provided with a positioning baffle 5 higher than the sub-frame body, the door and window frame 6 is fixed above the sub-frame 3 by screws 7, and the outer wall of the door and window frame 6 is against the place On the inner side of the positioning baffle 5, the gap between the door and window frame 6 and the sub-frame 3 is filled with a sealing foaming agent 8.

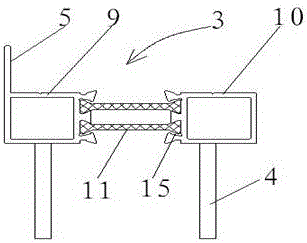

[0021] In this embodiment, the sub-frame 3 includes an outer frame 9, an inner frame 10, and heat insulation strips 11 connected between the inner and outer frames, and has a broken bridge structure with good heat preservation effect. The posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com