Bridge deck pavement surface layer structure and maintenance construction method

A bridge deck pavement and pavement layer technology, which is applied in bridge maintenance, bridges, bridge parts, etc., can solve the problems of difficult service life, poor waterproofness, and no revolutionary improvement in structural layers, etc., and achieves low project cost, Improve waterproof performance, good compression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

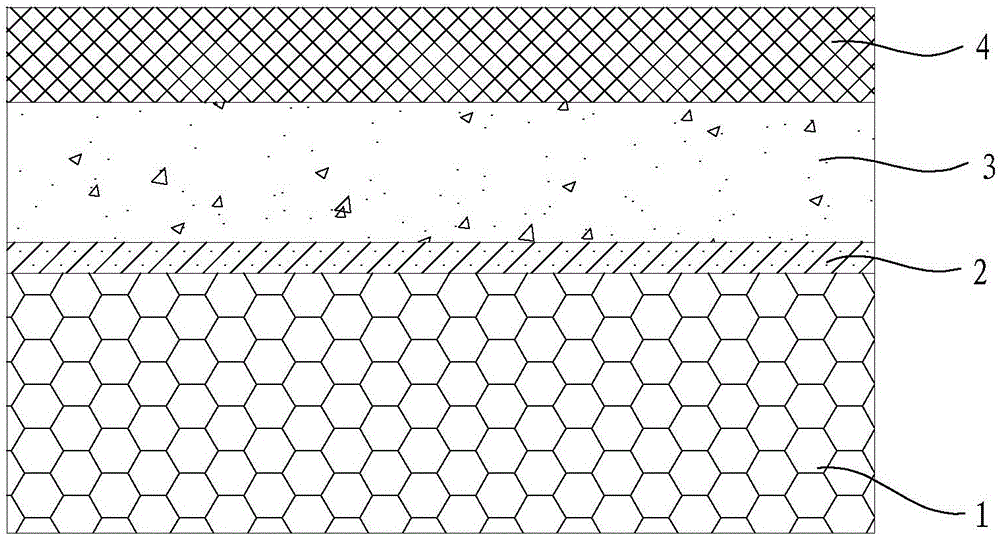

[0026] Such as figure 1 As shown, a bridge deck pavement surface structure in this embodiment includes a bridge deck concrete pavement layer 1, a bonded waterproof layer 2, a colloidal concrete pavement layer 3 and an anti-skid layer 4, wherein the bridge deck Concrete pavement layer 1 can adopt asphalt concrete pavement layer, bonded waterproof layer 2 is coated on the asphalt concrete pavement layer with ester binder as primer, colloidal concrete pavement layer 3 is made of curing agent, polyurethane and Aggregate is mixed, and the colloidal concrete pavement layer 3 is laid on the bonding waterproof layer 2 , and the anti-skid layer 4 is arranged on the colloidal concrete pavement layer 3 .

[0027] In this embodiment, the components of the ester binder include a thermosetting adhesive polyester, a catalyst and an oxidizing agent. The cata...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com