Section steel embedded type FRP (Fiber Reinforce Plastic) sectional material arch supporting structure

A supporting structure and section steel technology, which is applied in shaft lining, tunnel lining, underground chamber, etc., can solve the problems of brittle failure, poor durability, and low elastic modulus of FRP, and achieve good ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] I-shaped steel belongs to one type of section steel. The technical solution of the present invention will be described in detail below with reference to the drawings and embodiments.

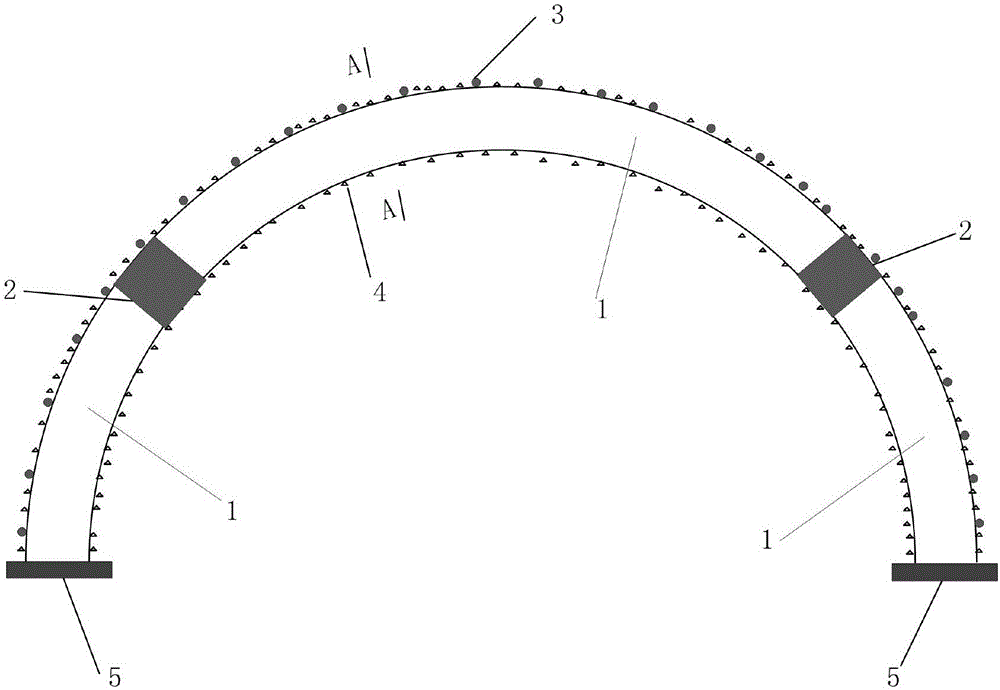

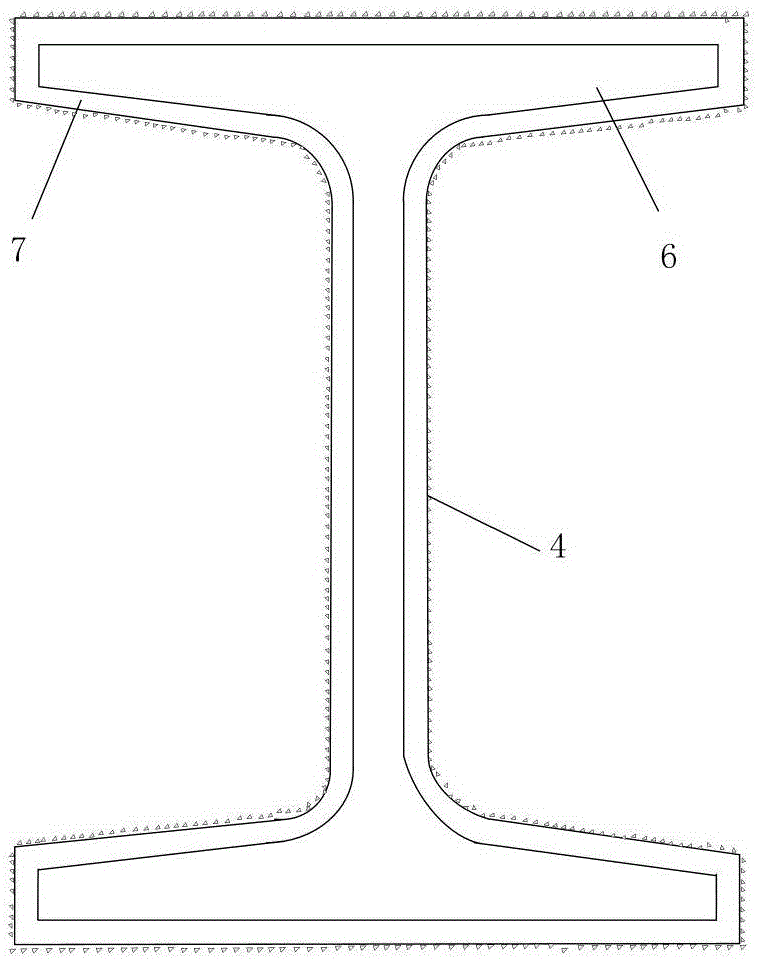

[0018] Such as figure 1 and figure 2 As shown, the present invention provides a FRP profile arch support structure embedded with I-shaped steel, and the FRP profile arch support structure embedded with I-shaped steel is welded by the FRP profile arch embedded with I-shaped steel and the longitudinal steel bar 3 made. The FRP profile arch is formed by connecting several FRP arc members 1 through connecting plates 2, and the FRP arc members 1 include I-shaped steel 6, FRP layer 7 and FRP layer fastened on the outer surface of I-shaped steel 6 Grit 4 on top.

[0019] The I-shaped steel 6 impregnated with epoxy resin and the fiber bundles impregnated with epoxy resin are fed into the pultrusion die together, and the volume ratio of the fiber bundles to the epoxy resin matrix after heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com