Cyclonic high sound intensity dust cleaning system

A cyclone and high-sound technology, applied in the field of cyclone-type high-sound-intensity ash cleaning system, can solve the problems of high equipment failure rate, large equipment installation, low operating efficiency, etc., and achieve high operating efficiency, convenient installation and debugging, and reduce cables. The effect of laying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

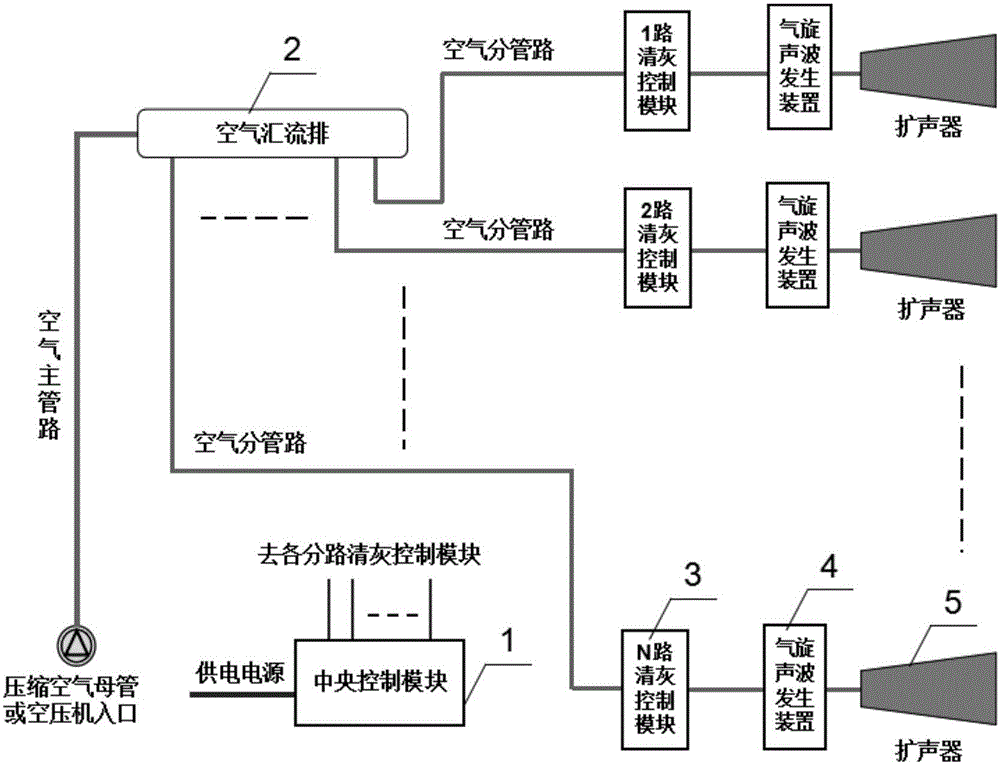

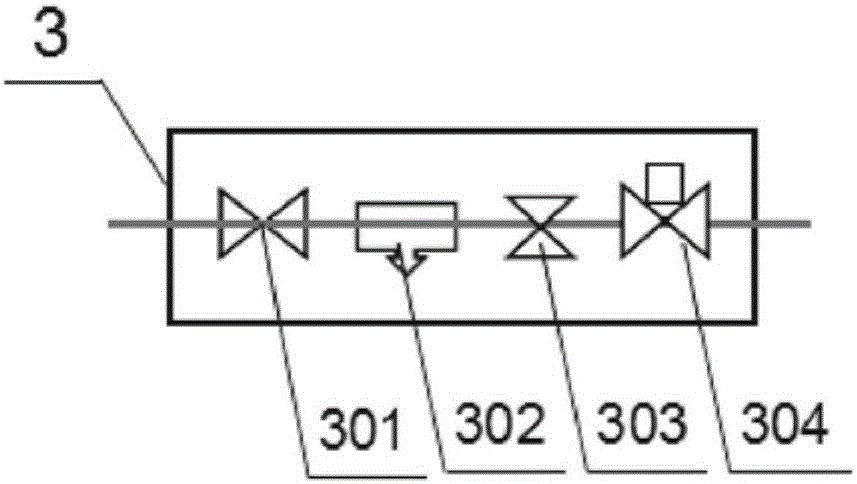

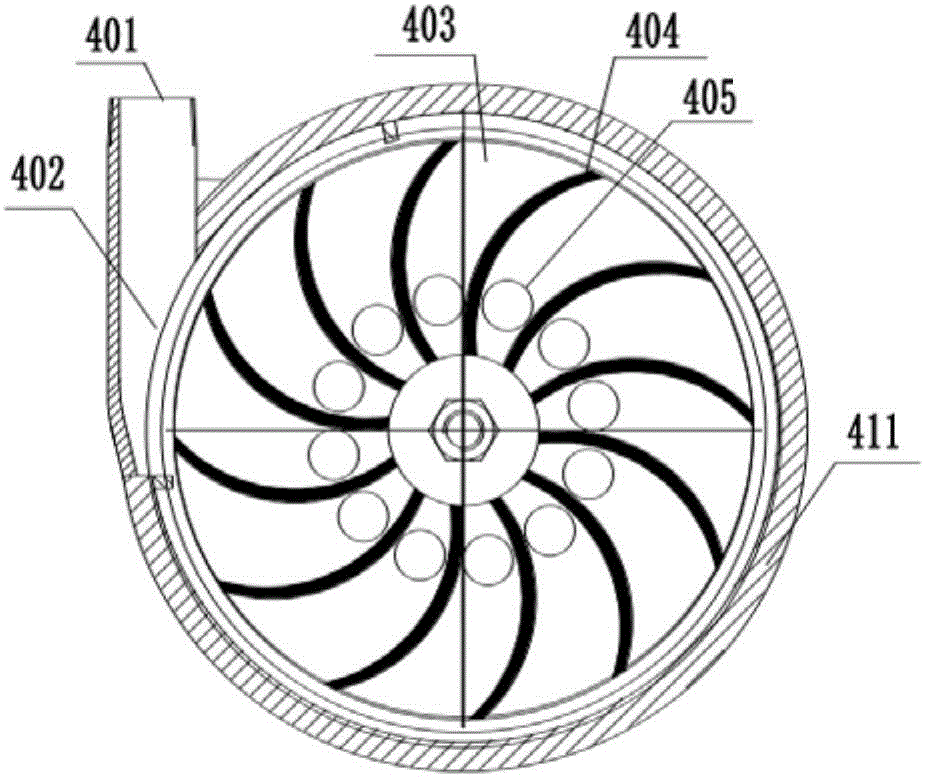

[0044] like figure 1 As shown, the present embodiment provides a cyclone-type high-sound intensity cleaning system, including a central control module 1, an air bus bar 2, a cleaning control module 3, a cyclonic sound wave generating device 4, and a loudspeaker 5; the central control The module 1 is connected to one or more of the dust removal control modules 3 by a circuit relationship through a control cable; the inlet of the air bus bar 2 is connected to the compressed air main pipe or the air compressor, and the compressed air main pipe or The air supply pressure of the air compressor is above 0.4MPa, preferably 0.5-1.0MPa; one or more outlets of the air busbar 2 and one or more air inlets of the dust removal control module 3 are corresponding The air path relationship is connected one-to-one; the air outlet of one or more of the cleaning control modules 3 is connected to the air inlet of one or more of the cyclone sound wave generating device 4 according to the correspond...

Embodiment 2

[0050] like Figure 5 As shown, this embodiment provides a cyclone type high-sound intensity cleaning system, wherein the blades on the rotating blade disc 404 in the cyclone sound wave generating device 4 are linear, and the other technical solutions of this embodiment are the same as those of Embodiment 1. .

[0051] The working process of a cyclone type high sound intensity cleaning system provided by the embodiment of the present invention is as follows:

[0052] like figure 1 As shown, the central control module 1 controls the opening or closing of the solenoid valve 304 of one or more ash removal control modules 3 according to the programmed control program; One or more outlets deliver compressed air to the air inlet of one or more ash removal control modules 3; After pressure or pressure regulation, through the opening or closing of the solenoid valve 304, the air inlet 401 of the connected cyclonic sound wave generator 4 is delivered or stopped, and the compressed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com