Biosafety asepsis room with monitoring function

A biosafety and sterile room technology, used in household appliances, heating methods, lighting and heating equipment, etc., can solve problems such as hidden safety hazards, interception, and difficult filtration of small organisms, and achieve reduced maintenance costs and high safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with the drawings and specific embodiments, the present invention will be described in detail. Before describing the technical solutions of the various embodiments of the present invention in detail, the terms and terms involved will be explained. In this specification, the same name or the same number Components represent similar or identical structures and are for illustrative purposes only.

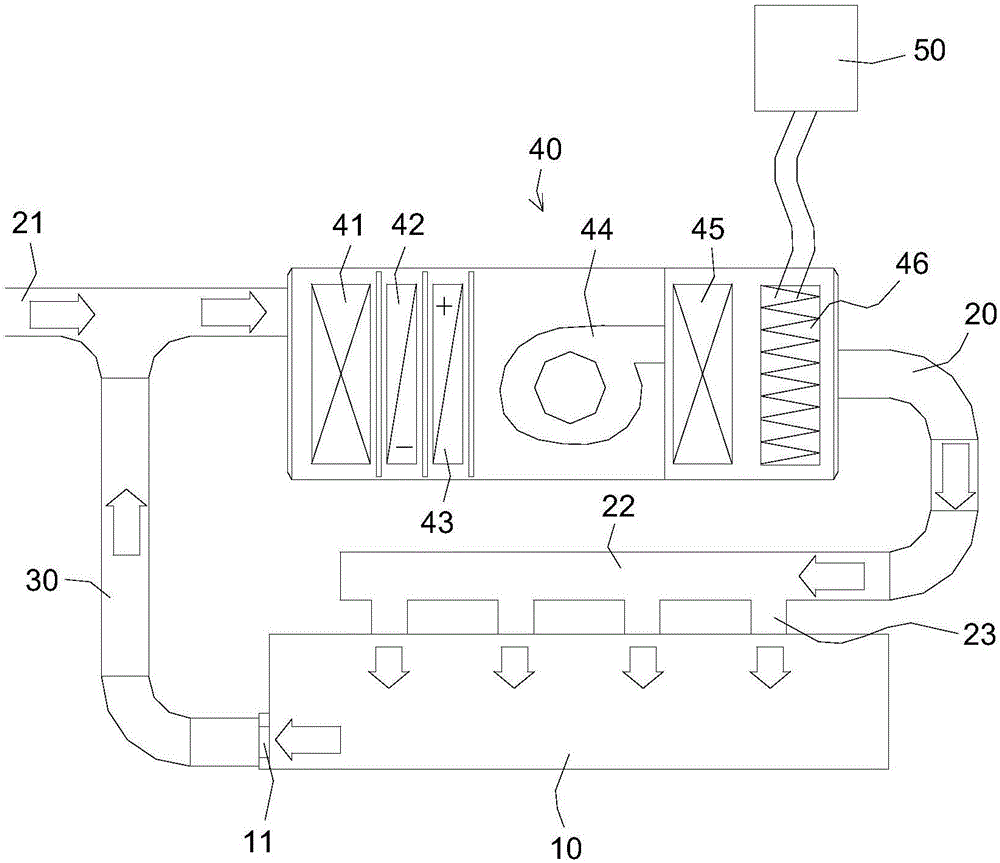

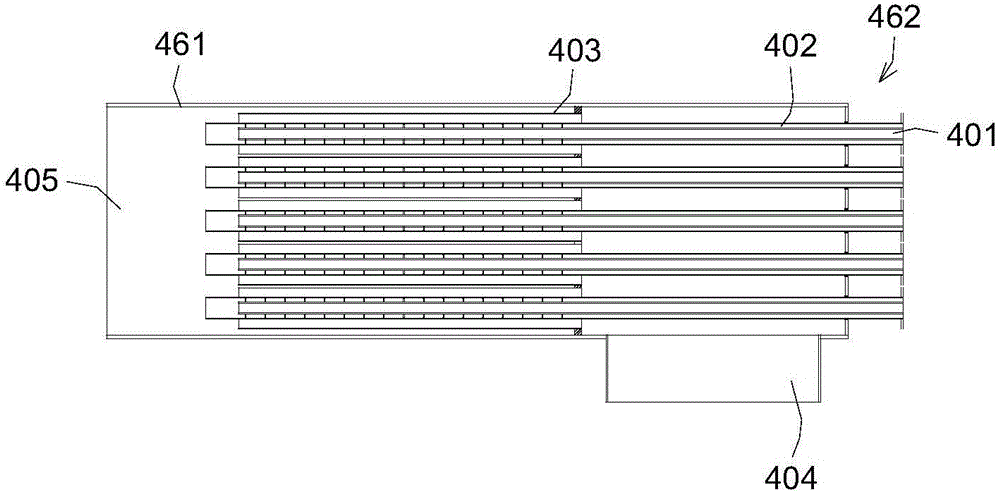

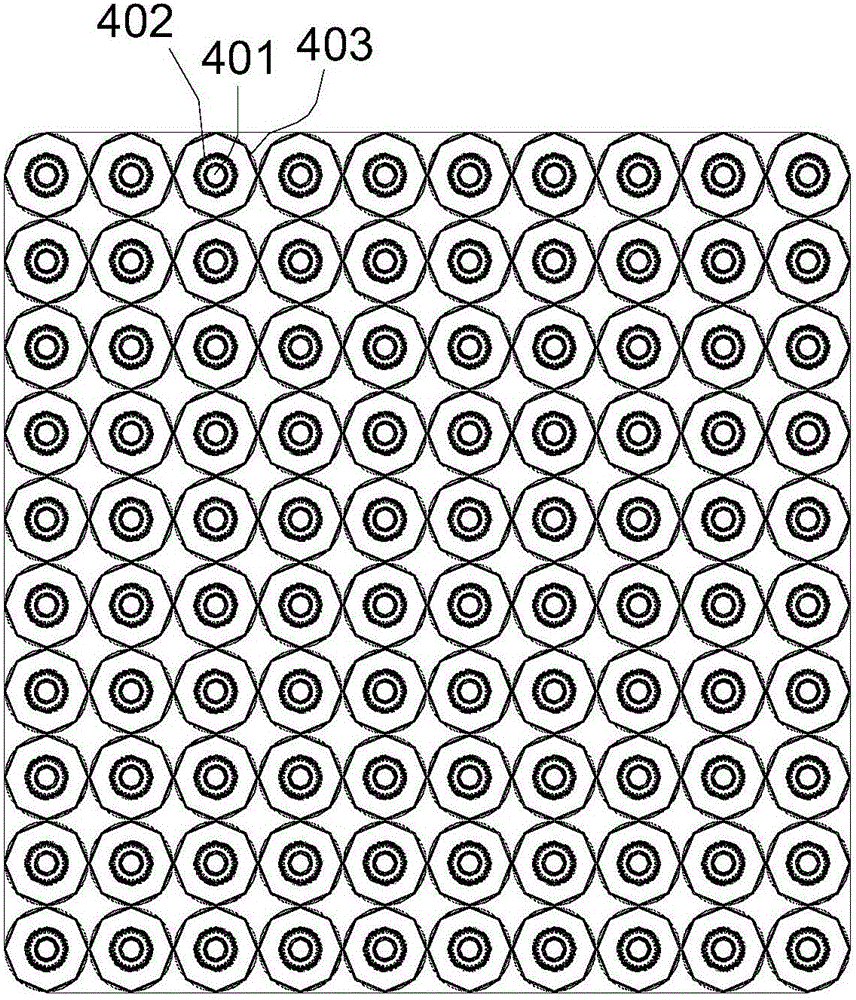

[0021] Such as figure 1 As shown, the biological safety level sterile room includes an aseptic operation room 10, an air supply pipe 20, a return air pipe 30, and a purifier 40 arranged in the air supply pipe. The air inlet 21 of the air supply pipe communicates with the outside, The air outlet 22 of the air supply pipe communicates with the aseptic operation room, and the air return port 11 of the aseptic operation room communicates with the air inlet of the air supply pipe through the air return pipe, and the air supply pipe communicates with the aseptic o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com