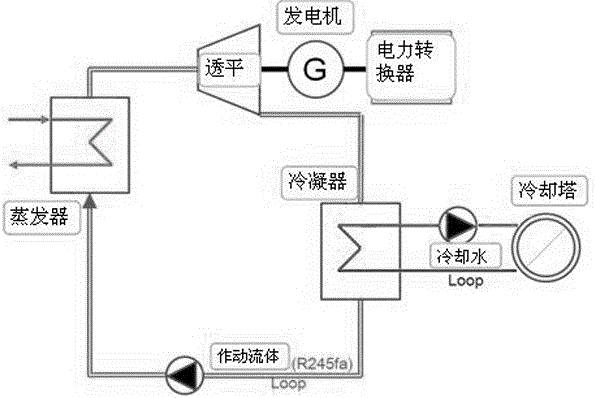

Composite heat exchanger for organic Rankine cycle power generating system

A heat exchanger and Rankine cycle technology, applied in the field of composite heat exchangers, can solve problems such as difficult, difficult to realize, and flow rate differences, and achieve the effect of reliable heat exchangers and small volumes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

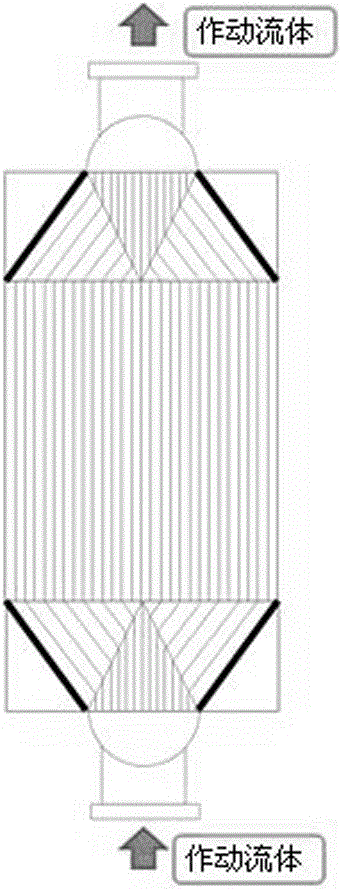

[0028] Example 1, such as Figure 4 , Figure 5 As shown, a composite heat exchanger for an organic Rankine cycle power generation system includes a liquid-phase sensible heat zone 1, a gas-liquid latent heat zone 2, and a gas-phase sensible heat zone 3.

[0029] The liquid-phase sensible heat zone 1 is arranged at the bottom of the heat exchanger. The liquid-phase sensible heat zone 1 is ring-shaped, and the liquid-phase sensible heat zone 1 is where the flow medium undergoing phase change undergoes heat exchange from a liquid-phase state.

[0030] The gas-liquid latent heat zone 2 is arranged in parallel with the liquid-phase sensible heat zone 1, and the annular inner surrounding space of the liquid-phase sensible heat zone 1 is the gas-liquid latent heat zone 2, and the gas-liquid latent heat zone 2 and the liquid-phase sensible heat zone 1 are connected. , the gas-liquid latent heat zone 2 has a larger cross-sectional area than the liquid-phase sensible heat zone 1, and ...

Embodiment 2

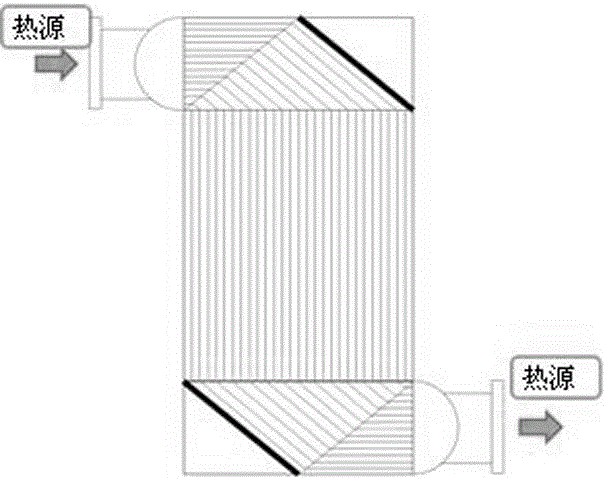

[0032] Example 2, such as Figure 4 , Figure 5 , Figure 6 As shown, a composite heat exchanger for an organic Rankine cycle power generation system includes a liquid-phase sensible heat zone 1, a gas-liquid latent heat zone 2, and a gas-phase sensible heat zone 3.

[0033] The liquid-phase sensible heat zone 1 is arranged at the bottom of the heat exchanger. The liquid-phase sensible heat zone 1 is ring-shaped, and the liquid-phase sensible heat zone 1 is where the flow medium undergoing phase change undergoes heat exchange from a liquid-phase state.

[0034] The gas-liquid latent heat zone 2 is arranged in parallel with the liquid-phase sensible heat zone 1, and the annular inner surrounding space of the liquid-phase sensible heat zone 1 is the gas-liquid latent heat zone 2, and the gas-liquid latent heat zone 2 and the liquid-phase sensible heat zone 1 are connected. , the gas-liquid latent heat zone 2 has a larger cross-sectional area than the liquid-phase sensible heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com