Preparation method of large-particle powder transmission electron microscope sample

A technique for TEM samples and large particles, which is used in material analysis, measurement devices, and instruments using wave/particle radiation. The effect of unclear problems, strong practicability and short sample preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

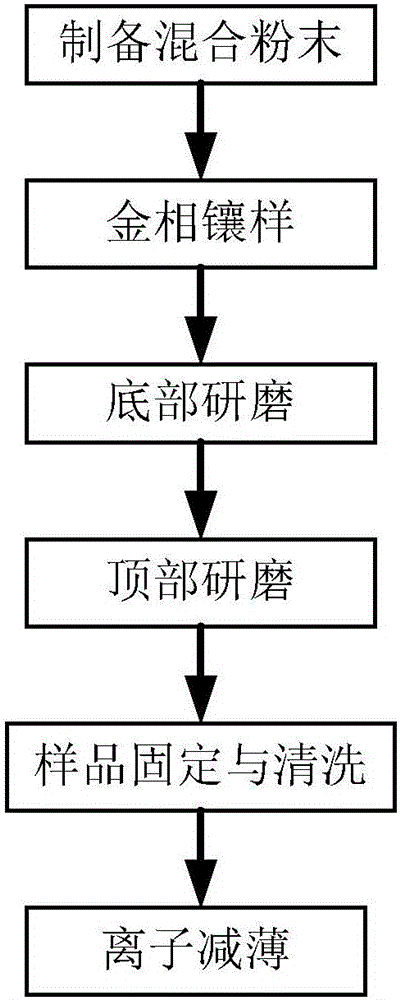

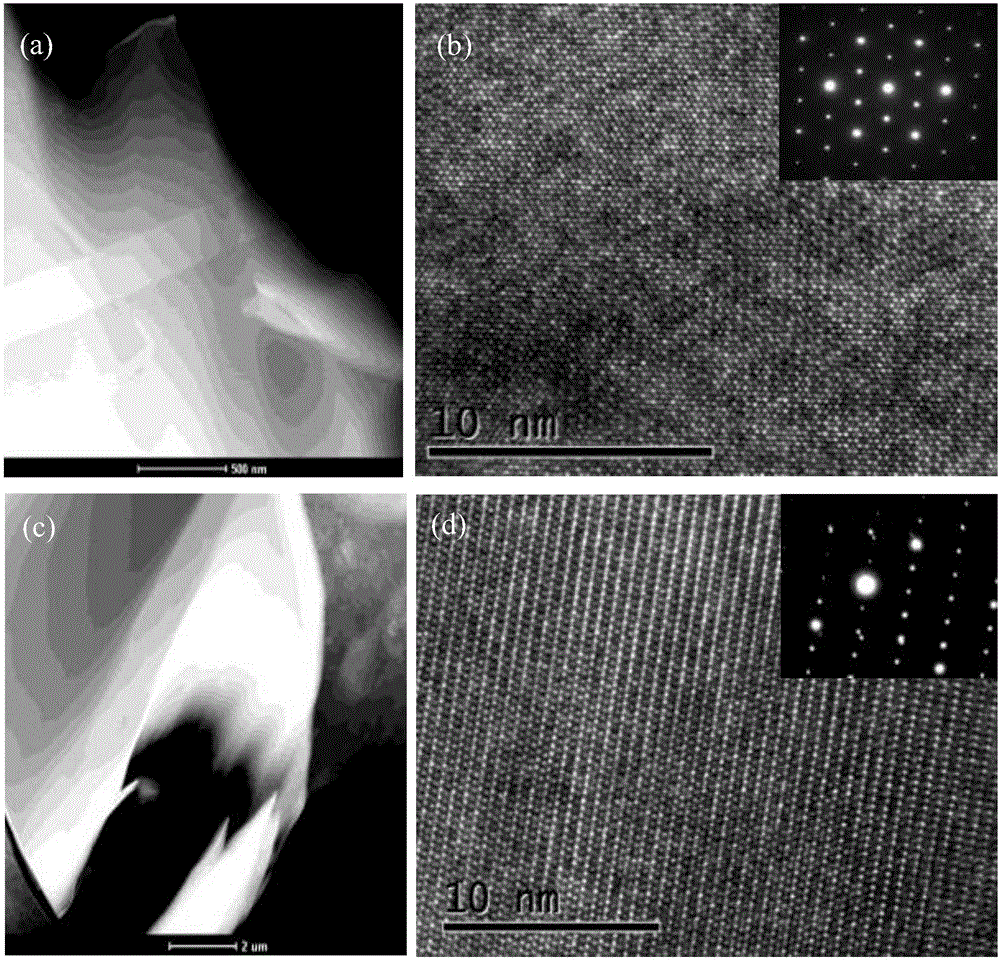

[0020] according to figure 1 According to the preparation process, the MnNiGe alloy brittle particle sample is mixed with carbon-containing conductive powder at a volume ratio of 1:99 to form a mixed powder; the mixed powder is put into a metallographic mounting machine, and the pressure of the mounting machine is controlled to 3MPa. The heating temperature is 180°C, the holding time is 2 minutes, and the cooling time is 3 minutes. Control the amount of mixed powder so that the height of the mounted sample is 0.5 cm and the diameter is 2 cm to make a metallographic sample; Melting will cause the large particle powder to settle to the bottom naturally, so directly grind the bottom of the metallographic sample with 4000 mesh sandpaper until the large particle powder can be seen, and the grinding time is 1min to make the initial grinding sample; The sandpaper of 2000 mesh and 2000 mesh is ground step by step, and the thickness of each sandpaper is about 100 μm, 50 μm and 35 μm re...

Embodiment 2

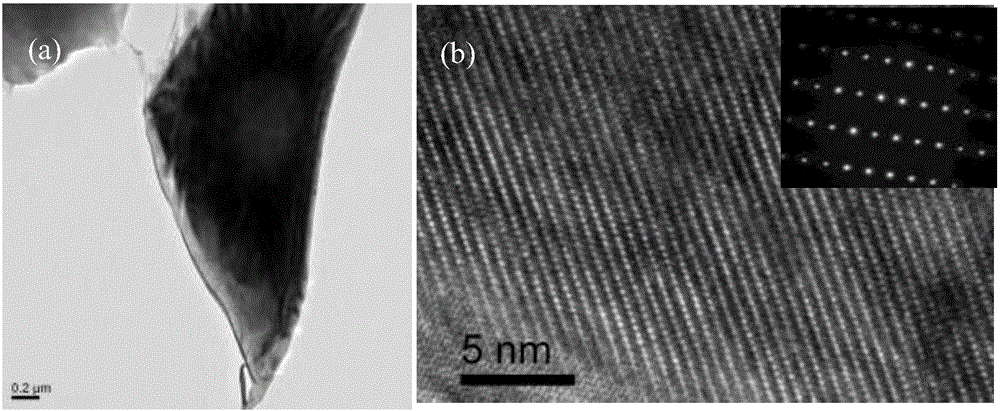

[0025] according to figure 1 The preparation process of the method is to take a large particle sample of MnCoGe alloy and mix it with carbon-containing conductive powder at a volume ratio of 1:4 to form a mixed powder; put the mixed powder into a metallographic mounting machine, and control the pressure of the mounting machine to 0.5MPa , the heating temperature is 150°C, the holding time is 5min, the cooling time is 3min, the amount of mixed powder is controlled so that the height of the mounted sample is about 0.5cm, and the diameter is 2cm to make a metallographic sample; The melting of the powder will cause the large particle powder to settle to the bottom naturally, so directly grind the bottom of the metallographic sample with 6000 mesh sandpaper until the large particle powder can be seen, and the grinding time is 3 minutes to make the initial polished sample; for the top of sample C, use 400 mesh , 1000-mesh and 2000-mesh sandpapers are ground step by step, and the thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com